-18- G1073/G1073Z 16" Bandsaw

Blade Guides

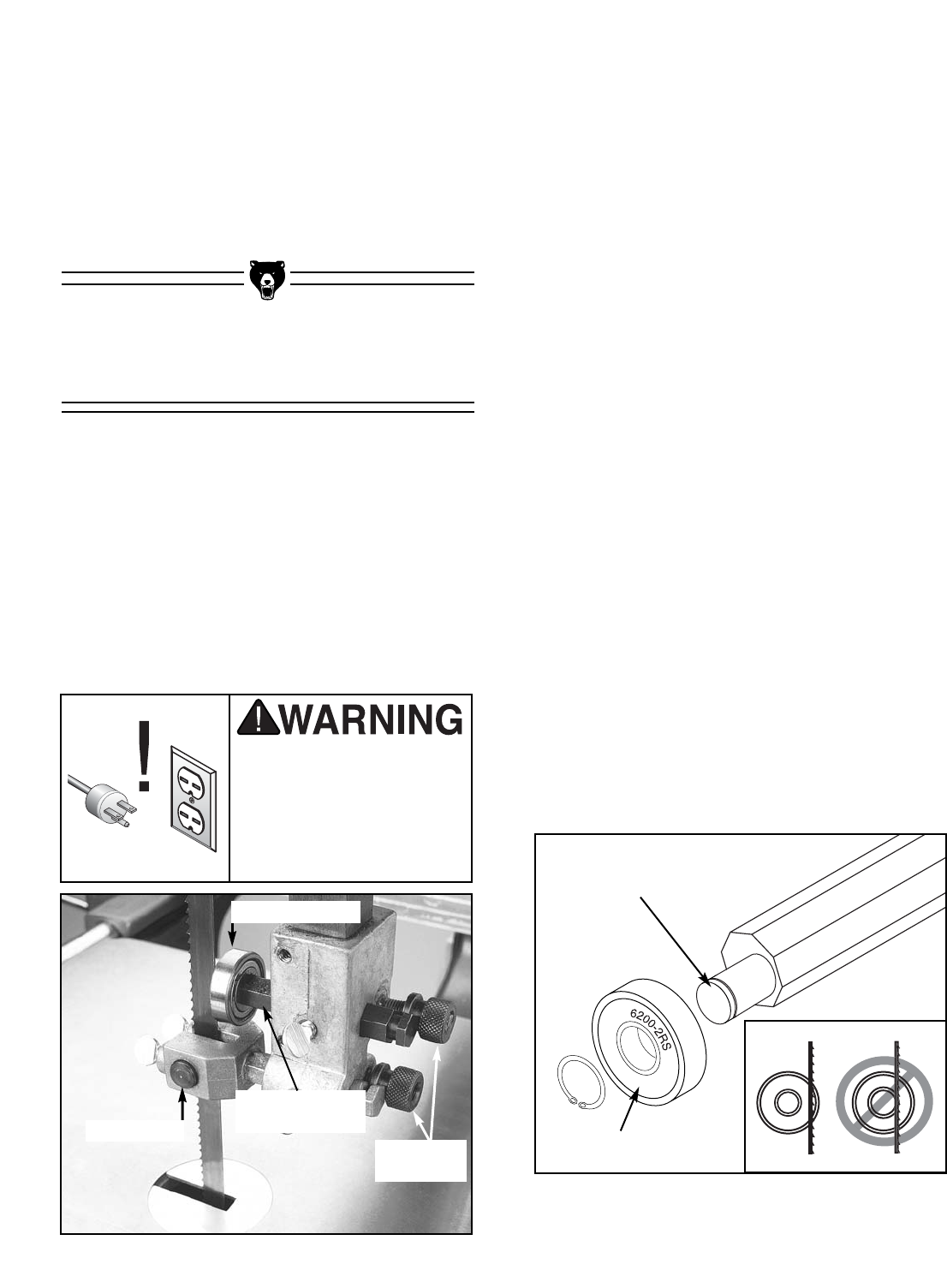

You must check the upper and lower support

bearings and guide blocks each time before start-

ing your bandsaw.

Always adjust the assemblies away from the

blade before installing a new blade or making

blade tracking adjustments. After blade tension

and tracking are set correctly, readjust the upper

and lower support bearings and guide block

assemblies into position. See Figure 18A control

locations.

Figure 18A. Upper guide assembly.

Figure 18B. Eccentric blade support.

Adjustment

Knobs

The support bearings back-up the blade during

the sawing operation. To adjust the support

bearings:

1. Loosen guide blocks and loosen the

setscrew that holds the guide block assem-

bly to the guide post. Remove the guide

block assembly.

2. Loosen the thumbscrew that secures the

support bearing shaft and unscrew the

adjustment knob that controls the support

bearing shaft. See Figures 18A/B for loca-

tions.

3. Remove the support bearing shaft from the

guide block assembly. Rotate the the shaft

so the blade will ride off-center against the

support bearing as shown in Figure 18B.

Install the shaft, tighten the mounting

setscrew and replace the adjustment cap.

4. Turn the adjustment cap so that the upper

and lower support bearings are approxi-

mately .016" (thickness of a dollar bill x 4)

behind the blade. Tighten the thumbscrews.

5. To adjust the lower support bearing, remove

the lower guide block assembly by taking out

the two setscrews that mount it to the band-

saw body. Make the same adjustments

described in steps 2-4 and mount the guide

block assembly back to the bandsaw body.

Support Bearing

Support Bearing

Shaft

Guide Block

Eccentric Shaft

Support Bearing

Always disconnect

power to the machine

when making adjust-

ments. Failure to do this

may result in serious

personal injury.

3. Tighten the lock collar and check the track-

ing.

For the best performance from your saw, regular-

ly maintain proper tracking of the blade.

For Coplanar Tracking, see the “Wheel

Alignment” instructions.