G1073/G1073Z 16'' Bandsaw -25-

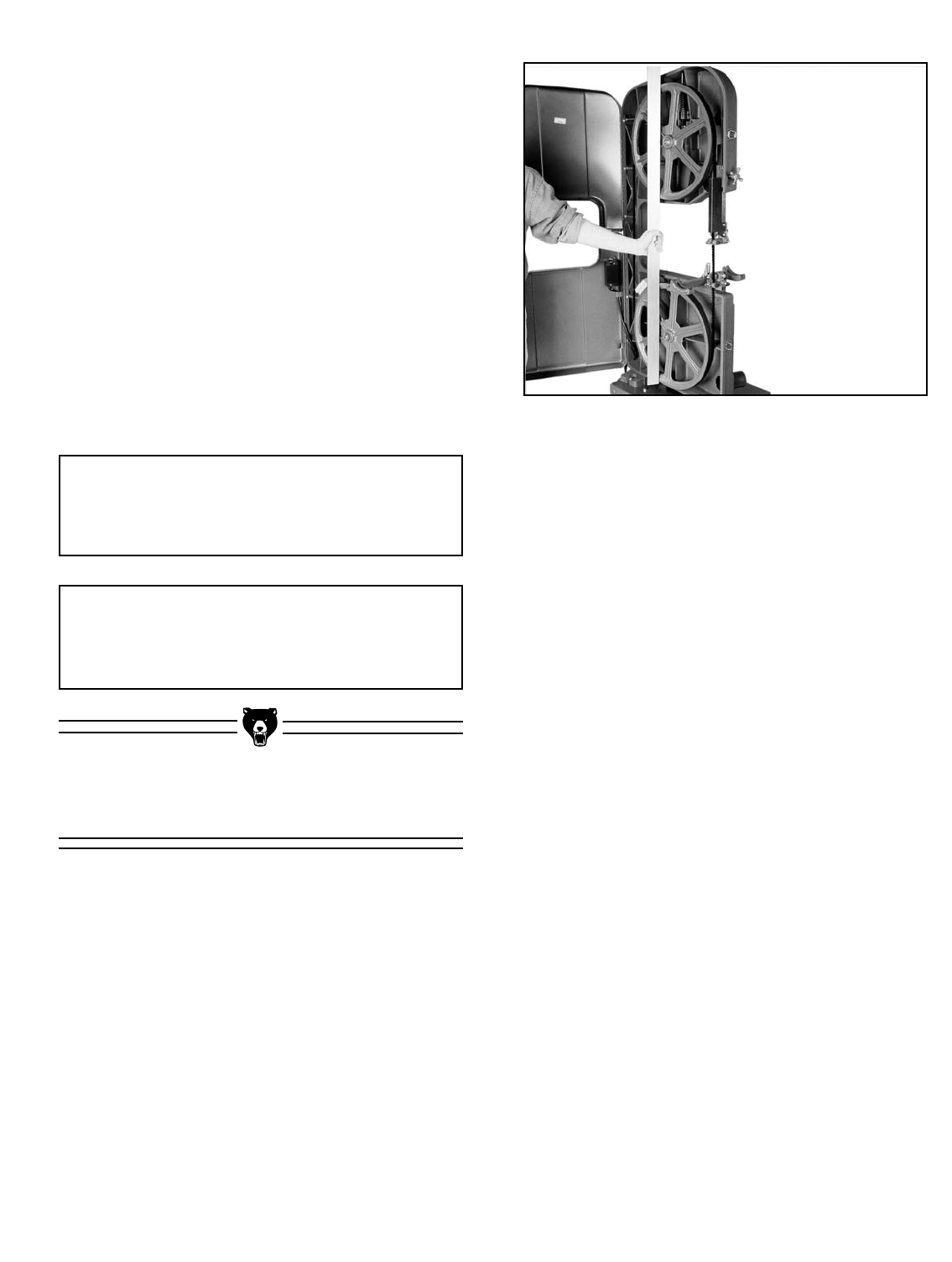

Figure 29. Holding a straightedge across both wheels.

Wheel Alignment

Wheel alignment is one of the easiest ways to

ensure you get optimal performance from your

bandsaw. When wheels are aligned, or coplanar,

the bandsaw is more likely to cut straight without

wandering; and vibration, heat, and blade wear

are considerably decreased because the blade is

automatically balanced on the wheel. This is

known as “Coplanar Tracking.”

To verify if the the upper and lower wheels are

coplanar:

1. With the blade on and properly tensioned,

hold a straightedge close to the center of

both wheels. Make sure it fully extends

across them as in Figure 29.

To compensate for lead if making straight

crosscuts using the miter gauge, you will

need to shift the table. To do this:

1. On a scrap piece of wood, mark a line that is

perpendicular to the front edge. Starting

where the line begins, cut the board by push-

ing it through the blade with the miter gauge.

2. Loosen the table mounting bolts according to

the instructions about “Table Parallelism” on

page 20. Shift the table to compensate for

the blade lead.

3. Repeat steps 1 and 2 until the blade cuts

straight when wood is pushed through with

the miter gauge.

NOTICE

Lead adjustments will change when new

blades are mounted in the saw.

NOTICE

If the table is shifted, the fence will be affect-

ed since it is attached.

2. A perfectly coplanar set of wheels will allow

the straightedge to touch the top and bottom

of the outside rims on each wheel. If this is

the case with your wheels, then they are

coplanar.

3. If your wheels are not coplanar, check them

for adjustment by placing the straightedge

on the upper wheel first – ensuring that it

touches both the top and bottom rim – and

adjust the tracking knob to see how the

straightedge lines up with the lower wheel.

If the straightedge only touches the top rim of

the lower wheel, then the upper wheel needs

to be shimmed.

If the straightedge only touches the bottom

rim of the lower wheel, then the lower wheel

needs to be shimmed.

Shimming a wheel.

1. Adjust the tracking knob so the top wheel is

parallel with the bottom wheel. With the

straightedge touching both points of the

wheel that does not need to be adjusted,

measure the distance away from the incor-

rect wheel with a fine ruler. See Figure 30.

The distance you measured with the ruler is

the distance the wheel must be corrected.