-20-

G4015Z Lathe/Mill

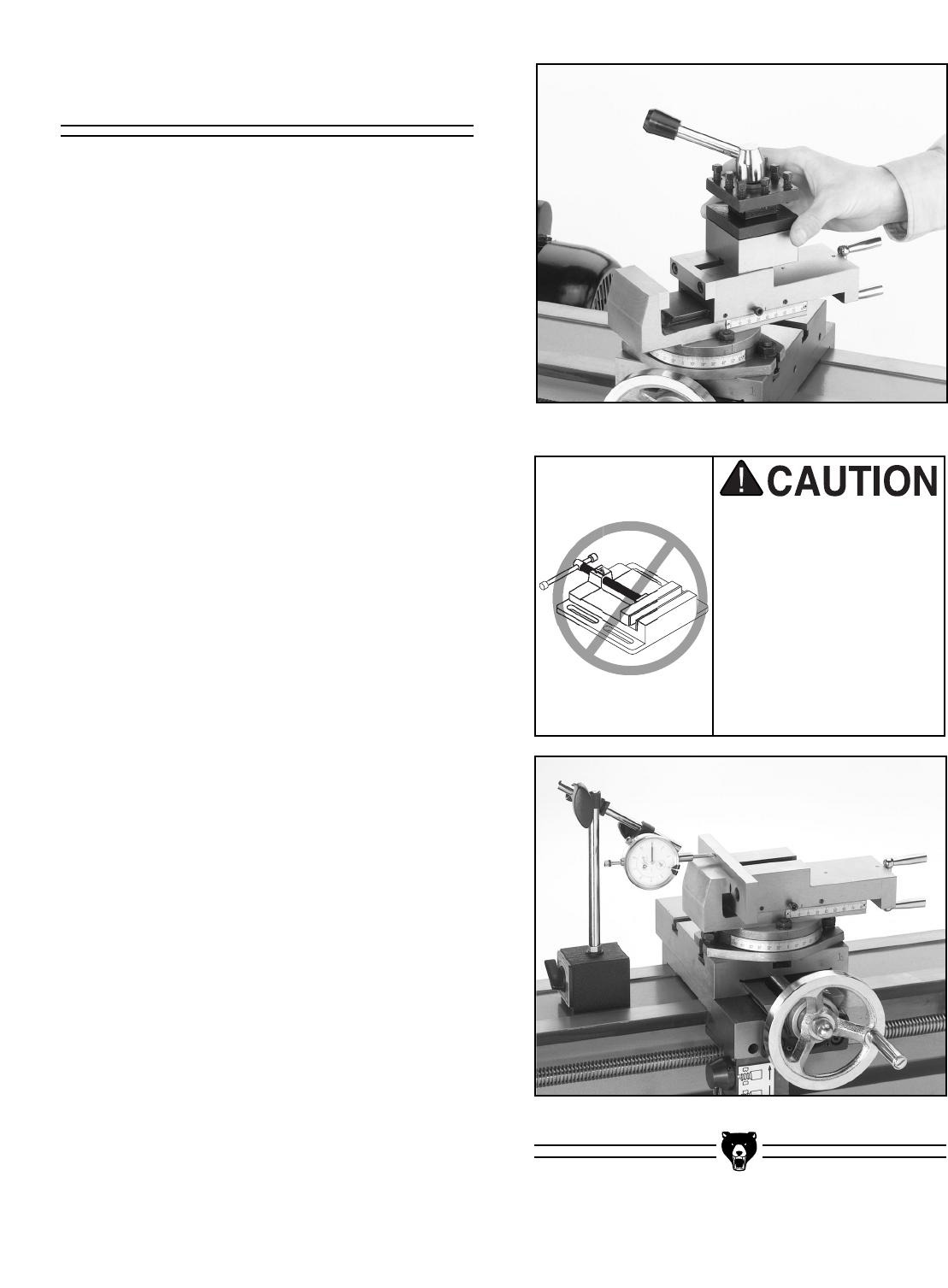

Machine Vise

The Model G4015Z comes supplied with a milling

vise which also serves as the compound for the

lathe. The 4-way tool post must be removed

before using the vise. Loosen the lock handle

and slide the tool post off of the compound/vise

as in Figure 13.

The milling vise can be aligned to 1 of the 2 axes

of the lathe or at any angle desired. Care must be

given to setting the vise if a precision angle is

needed. The following instructions are given to

make the jaws parallel to the travel of the cross

slide.

1. Remove the tool post as described above.

2. Loosen the swivel bolts on the

compound/vise so it can swivel freely. Pivot

the compound/vise so the jaws of the vise

are roughly aligned with the cross slide.

3. Mount the drill chuck into the milling spindle

and secure an indicator into it or, place a dial

indicator mounted to a magnetic base on the

bed as in Figure 14.

4. Position the cross slide and apron so the

indicator point contacts the stationary vise

jaw or a parallel mounted into the vise.

5. Move the cross slide with the hand wheel

and watch the dial. Note the direction the

needle is moving on the dial and by how

much.

6. When the vise has moved so the indicator is

at the other end of the parallel, pivot the vise

one half the amount of motion detected in

step 6.

7. Move the vise to the starting position and

note the difference. Again, pivot the vise one

half the difference.

8. Repeat steps 6 through 8 until the dial

remains stationary when the vise is moved.

9. Tighten the pivot bolts on the base of the

compound/vise.

Figure 13. Sliding the tool post off.

Figure 14. Aligning vise for precision.

Never use a vise for

milling unless it is rated

for milling machines.

Drill press or bench

vises are not designed

for the rigors of machin-

ing. Vise failure during

a milling operation may

lead to serious personal

injury.