H8203 Professional Drill Sharpening Machine

-13-

SECTION 4: OPERATIONS

Damage to your eyes and lungs could result

from using this machine without proper pro

-

tective gear. Always wear safety glasses and

a respirator when operating this machine.

Loose hair and cloth-

ing could get caught in

machinery and cause seri

-

ous personal injury. Keep

loose clothing and long

hair away from moving

machinery.

NOTICE

If you have never used this type of machine

or equipment before, WE STRONGLY REC

-

OMMEND that you read books, trade maga

-

zines, or get formal training before begin

-

ning any projects. Regardless of the con

-

tent in this section, Grizzly Industrial will

not be held liable for accidents caused by

lack of training.

Operation Safety

Overview

The Model H8203 features a tapered CBN (cubic

boron nitride grinding wheel that sharpens twist

drill bits using a three-step process. The included

CBN grinding wheel sharpens HSS, TiN-coated,

and cobalt bits. An optional SDC 170 grinding

wheel (Page 19) sharpens carbide bits.

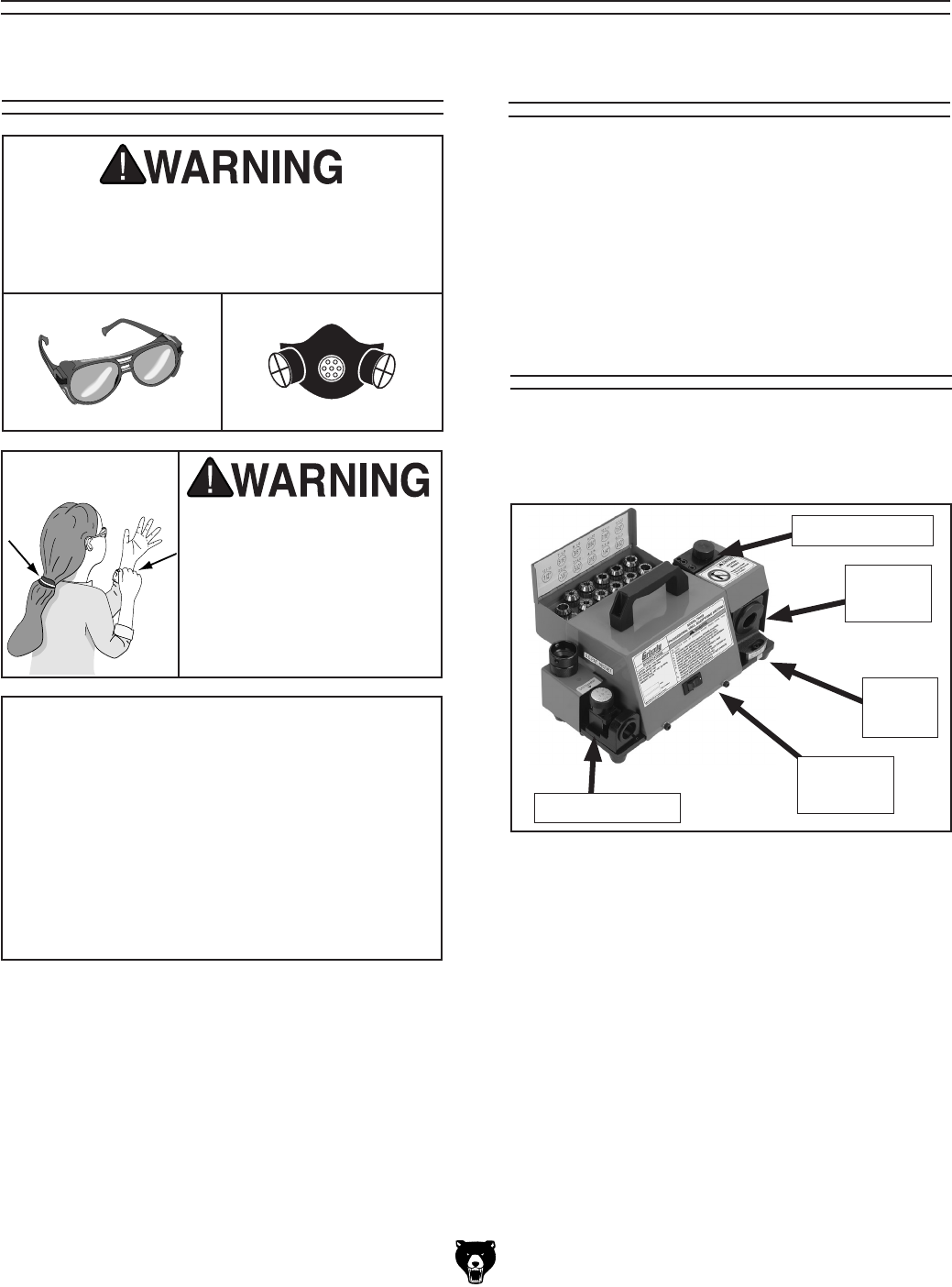

Figure 8. H8203 controls.

Basic Controls

Below is a list of the basic controls on the Model

H8203. Use the list with Figure

8 to become

familiar with your drill sharpening machine.

Calibrating Dial: Matches drill bit with correctly

sized collet. Ensures drill bit is correctly posi

-

tioned in the collet holder.

Trimming Area: Location where grinding wheel

thins the drill bit web.

Grinding

Area

ON/OFF

Switch

Angle

Scale

Calibrating Dial

Trimming Area