-14-

H8203 Professional Drill Sharpening Machine

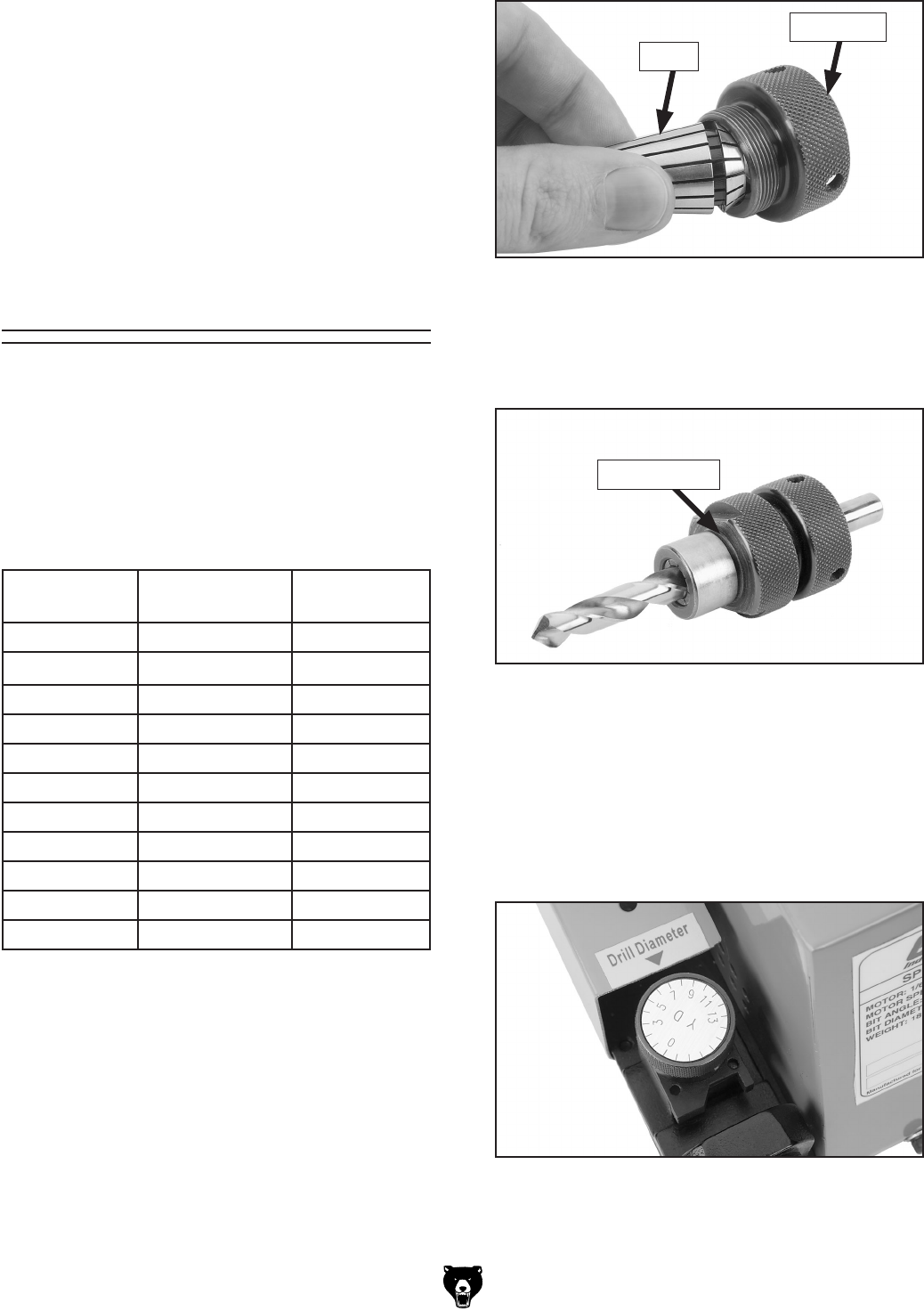

Figure 11. Calibrating dial set for a 7mm drill bit.

4. Turn the calibrating dial right until it stops at

the "0" position, then align the arrow on the

calibrating device with the number on the dial

that corresponds to the drill bit diameter.

For example, turn the dial to "7" for a 7mm

diameter drill bit, as shown in

Figure 11.

The following steps must be done to prepare the

drill bit to be sharpened.

To calibrate the drill bit:

1. Use the chart below or the one on the collet

tray cover to select the appropriate collet for

your drill.

Figure 9. Inserting collet into lock ring.

3. Thread the collet holder onto the lock ring two

turns for now, and insert the drill bit into the

collet holder as shown in

Figure 10.

Figure 10. Drill bit installed in collet holder.

Lock Ring

Collet

Collet Holder

Angle Scale: Indicates the point angle to be

sharpened; the angle can be adjusted from 90º—

140º depending upon the workpiece material to

be drilled.

Grinding Area: Location where the CBN wheel

grinds the drill bit point angle to the selected

angle.

ON/OFF Switc

h: Turns the machine ON or OFF.

2. Insert the collet at a slight angle into the lock

ring, as shown in

Figure 9.

Metric Size Fractional-

Inch Size

Collet No.

2.0-3.0 Less than

1

⁄8" 3 2

3.1-4.0

1

/8"-

5

/32" 4 3

4.1-5

11

/64"-

3

/16" 5 4

5.1-6

13

/64"-

1

/4" 6 5

6.1-7

17

/64"-

9

/32" 7 6

7.1-8

19

/64"-

5

⁄16" 8 7

8.1-9

21

/64"-

23

/64" 9 8

9.1-10

3

/8"-

25

/64" 10 9

10.1-11

13

/32"-

7

/16" 11 10

11.1-12

29

/64"-

15

⁄32" 12 11

12.1-13

31

/64"-

1

⁄2" 13 12

Calibrating Drill Bit