H8203 Professional Drill Sharpening Machine

-17-

3. While pressing the collet holder forward

gently, rotate the drill bit back and forth, and

about every four seconds, dip the bit in water

to cool the tip. This will help prevent the tip

from overheating and softening too much.

4. Continue grinding until the machine stops

making grinding sounds.

5. Remove the collet holder and drill bit, rotate

them 180º, then reinsert the collet holder and

drill bit into the front grinding area.

6. Repeat Steps 3 & 4.

7. Examine the point angle.

—If the point angle is even on both sides

of the bit, (

Figure 16), and no unground

material remains, as shown in

Figure 20,

the point angle is correct. Now,

go to Rear

Trimming Area to grind a back angle.

Note

: It is not necessary to grind a back relief

on a standard bit. However, doing so will

ensure the bit cuts more efficiently.

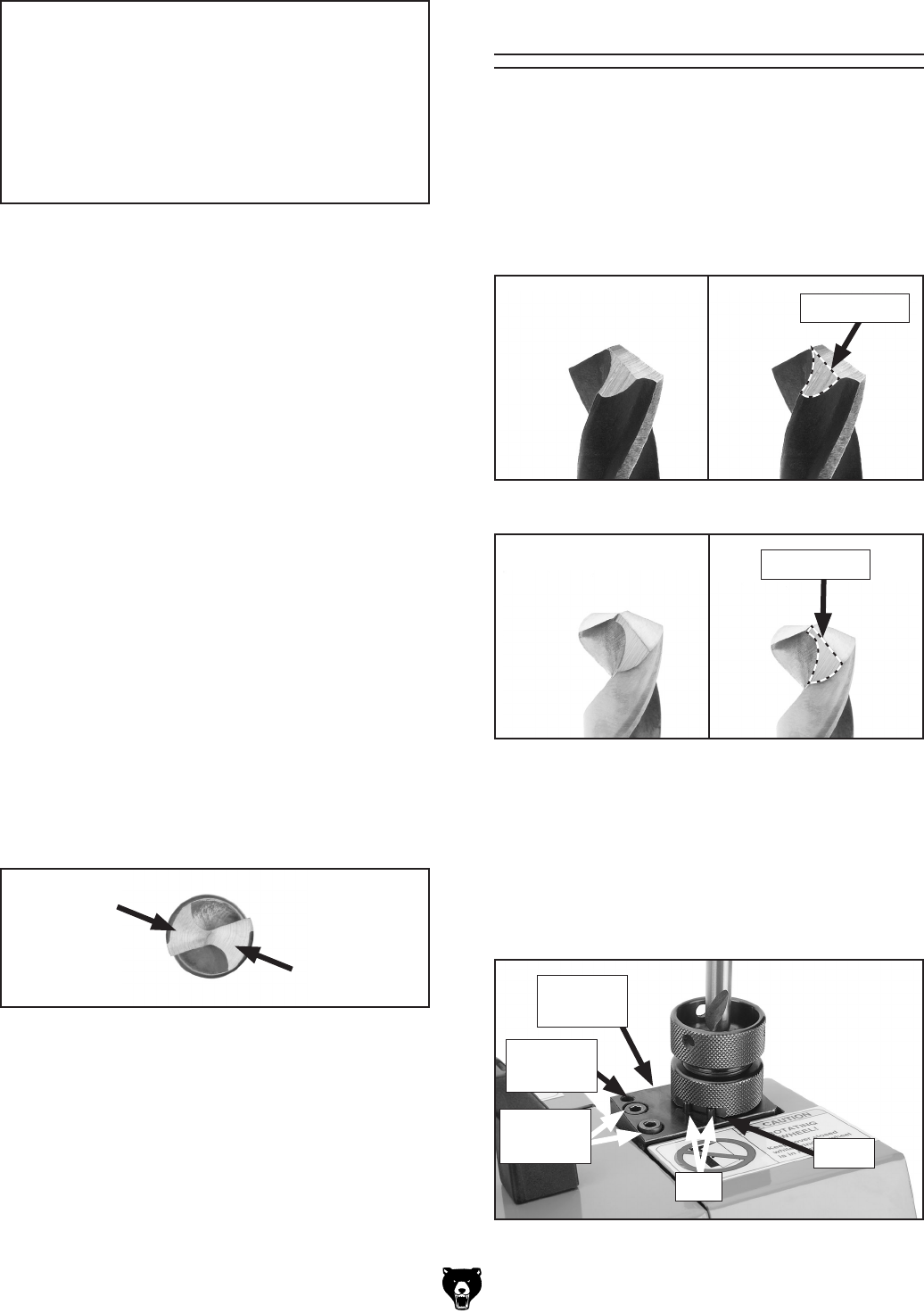

Rear Trimming Area

The grinding wheel grinds a back relief on stan-

dard and split point bits in the rear trimming area.

Adding back relief to a standard bit makes it more

efficient in removing material from a workpiece.

Some trial and error will be needed to determine

the correct amount of back relief, as shown in

Figures 21 & 22.

Figure 21. Correct back relief for standard bit.

Back Relief

Figure 22. Correct back relief for split point bit.

Figure 23. Collet and bit inserted into rear

trimming area.

Notch

Pins

Cap

Screws

Set

Screw

Adjusting

Block

To add back relief to a standard bit:

1. Loosen the cap screws (Figure 23) on the

rear trimming area and lower the set screw

to raise the adjusting block to its highest posi

-

tion.

Figure 20. No unground surfaces remain on bit

after point angle grinding (top view).

—If the surface of the drill bit retains unground

material, try grinding the bit again, or use a

different point angle setting.

—If the point angle is not shaped evenly,

repeat Steps 1-6, using even pressure to

grind both sides of the bit.

Back Relief

NOTICE

You can ruin a drill bit by grinding it too

long or too forcefully. Frequently dip the

bit in water to cool it and retain its original

hardness. If the tip becomes blue or purple,

it may have overheated and be too soft to

use.