H8203 Professional Drill Sharpening Machine

-19-

Drill Sharpening

Accessories

The following accessories are available for the

Model H8203:

T20238—CBN Grinding Wheel

Sharpens HSS, Tin-coated, and cobalt bits.

T20239—SDC Grinding Wheel

Sharpens carbide bits.

SECTION 5: MAINTENANCE

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person

-

al injury.

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily/Weekly Check

:

• Clean chips from grinding/trimming areas

and inside grinding wheel cover.

• Any other unsafe condition.

Monthly Check:

• Worn or damaged grinding wheel.

• Loose fan.

Schedule

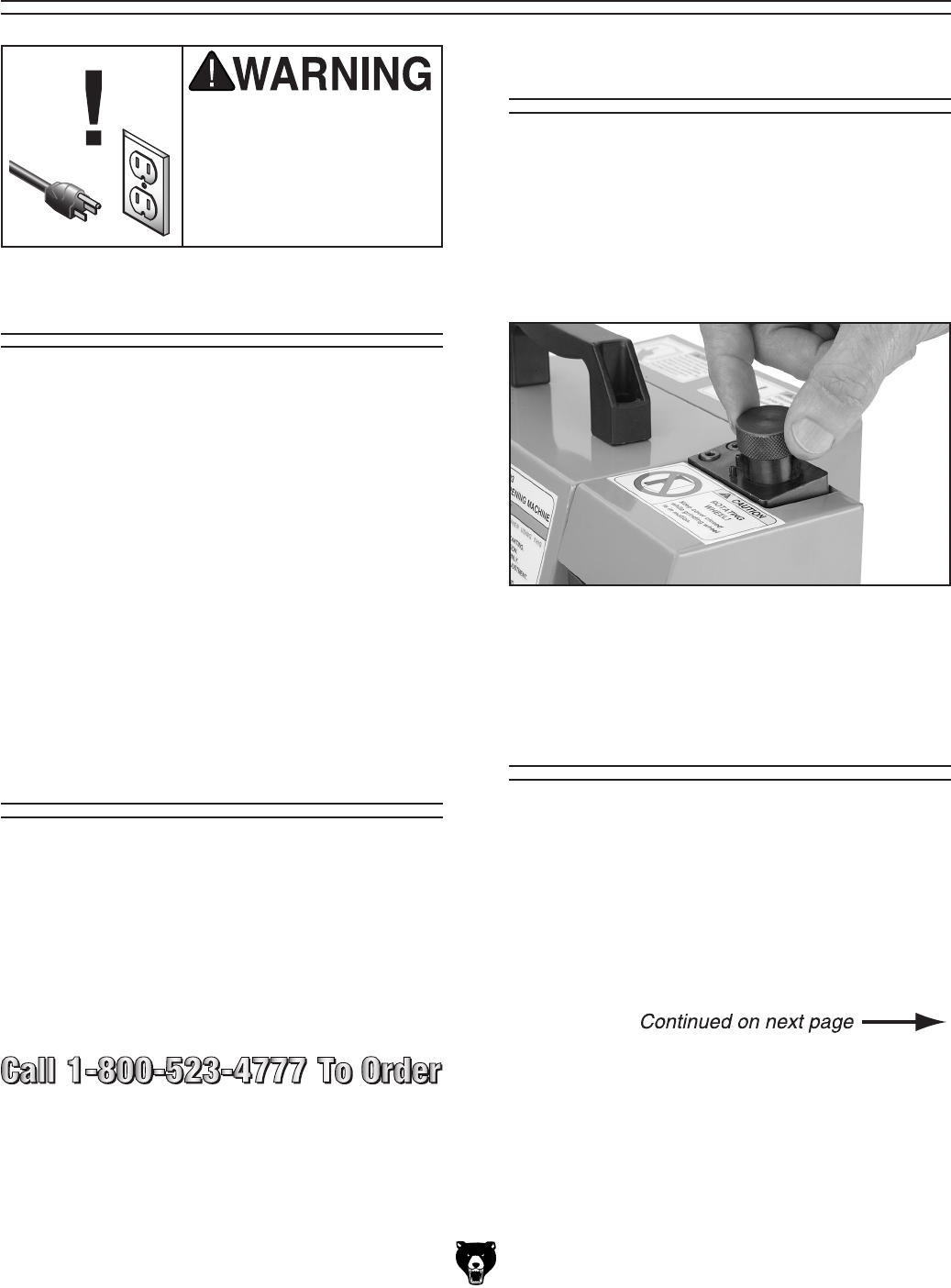

Cleaning the Model H8203 is relatively easy. Use

a vacuum or brush to remove excess metal chips

from around the grinding and trimming areas and

inside the grinding wheel cover. Use the included

cleaning brush (Figure 27) to clean the front

grinding and rear trimming shafts. Use a cloth to

remove remaining dust.

Cleaning

Changing Grinding

Wheel

A CBN 170 grinding wheel for sharpening HSS,

TiN-coated, and cobalt bits is preinstalled in the

H8203. Replace this grinding wheel when it no

longer sharpens drill bits to your satisfaction. How

often you will need to replace the grinding wheel

depends upon how often you use the machine.

You can also install the optional SDC 170 grinding

wheel, which sharpens carbide steel bits.

Figure 27. Cleaning rear trimming area.