-22-

H8203 Professional Drill Sharpening Machine

Sharpening Operations Continued

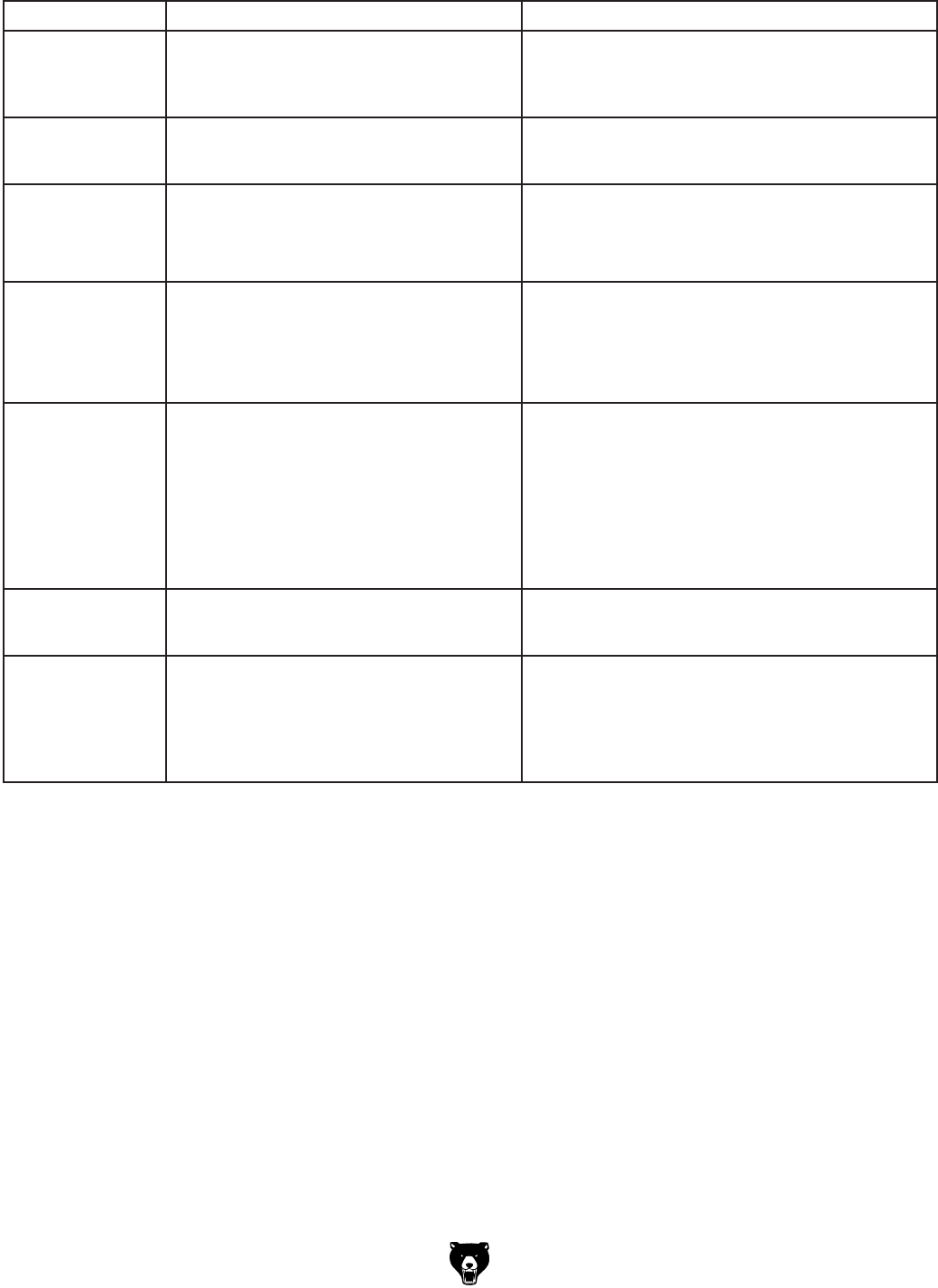

Symptom Possible Cause Possible Solution

Drill bit point over-

split and chisel

edges have been

removed.

1. Adjusting block set too low.

2. Adjusting block not secured; blocks sags,

allowing wheel to grind bit too much.

1. Regrind bit in front and rear areas, but do not lower

adjusting block so much.

2. Secure adjusting block before grinding.

Amount of back

relief ground into bit

is too small.

1. Adjusting block not low enough. 1. Lower adjusting block more (

Page 18).

Heavy grinding nois

-

es. Drill bit smokes

or tip has a black,

blue, or purple hue.

1. Too much pressure applied on drill bit dur

-

ing grinding.

2. Tip is too hot and may have been softened

too much.

1. Use less pressure (

Page 15) and take longer to

grind the bit.

2. Try using the bit. If it dulls quickly the tip was soft

-

ened.

Standard drill bit

point skips or

does not cut into

workpiece.

1. Bit has no back relief grind.

2. Heel is higher than cutting lip or is curved

up.

1. Follow instructions for grinding a back relief to

improve drill bit performance (

Page 14).

2. Regrind the point angle until it is correct. If the heel

is curved up, follow instructions for grinding a back

relief.

Notch on collet

holder will not fit into

grinding area flange

edge. Bit retains

unground material

or part of prior angle

after grinding in front

area.

1. Point angle on bit may be different from

angle set on front grinding area.

1. Select a point angle that matches or is closer to the

existing drill bit point angle. Continue grinding the

point angle (if between 118° and 135°) until the old

angle is removed.

Back relief ground

into opposite cutting

edge.

1. Adjusting block center point not directly over

grinding wheel edge.

1. Set center of adjusting block over edge of grinding

wheel (

Page 18).

Bits smoke or burn

consistently or it

takes a much lon

-

ger time to grind the

point angle or back

relief than normal.

1. The grinding wheel is dull. 1. Disconnect power and replace the grinding wheel

(Page 20).