-18-

H8203 Professional Drill Sharpening Machine

To prevent getting burned during the next

step, do not touch the end of a freshly

ground bit, which may be hot.

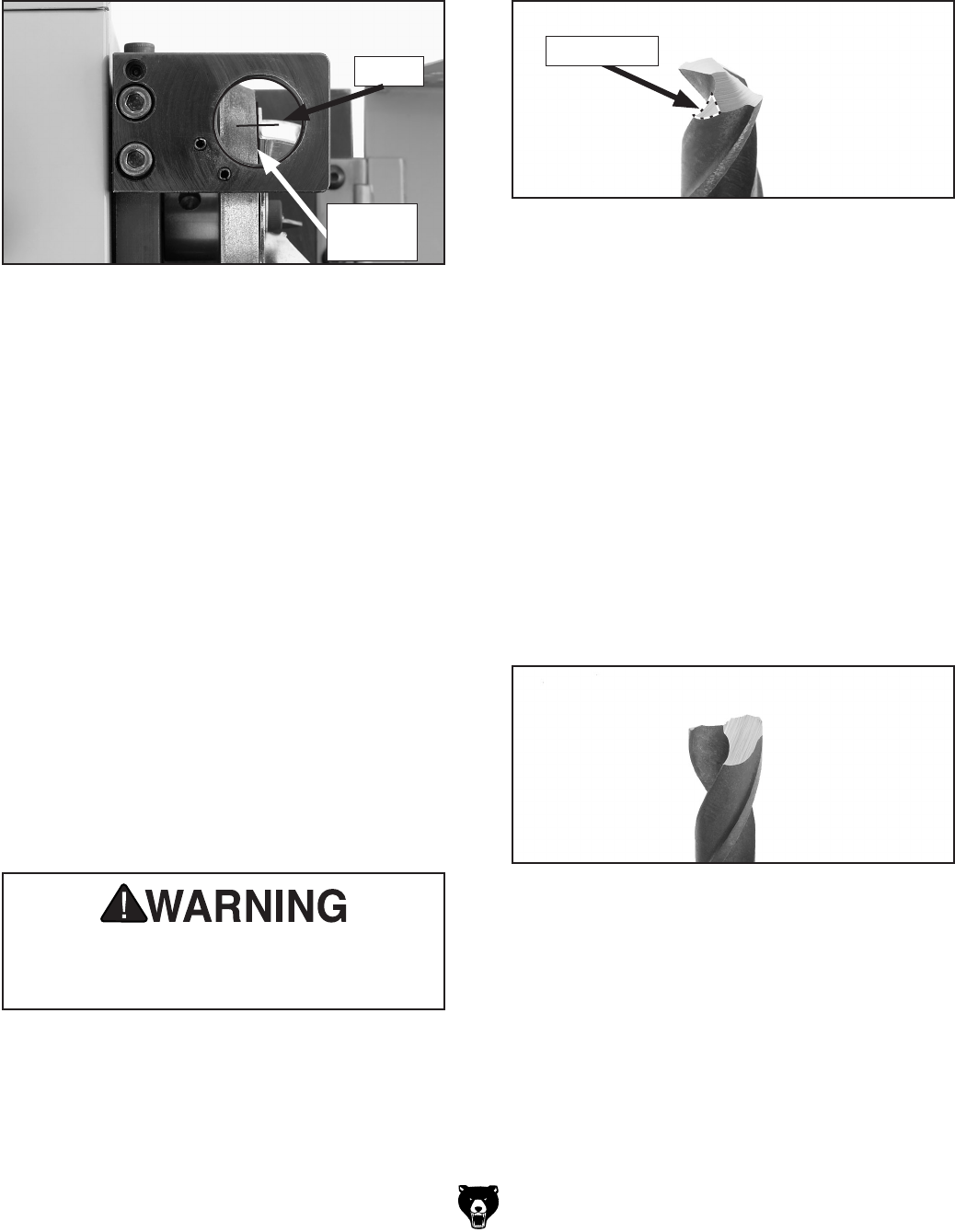

2. Tighten the cap screws, making sure the cen-

ter of the rear trimming hole is over the edge

of the grinding wheel, as shown in

Figure

24.

— If the back relief is not sufficient (Figure

25), continue lowering the adjusting block

until the back relief looks like the example

in Figure 21.

3. Make sure the grinding wheel cover is

secured, turn the machine

ON, and wait for

the machine to reach full speed.

4. Insert the collet holder and bit into the rear

trimming area so the pins fit into the notch on

the collet holder as shown in

Figure 23.

5. Press the collet holder and bit down, and

after about four seconds dip the tip in water.

Continue alternating between grinding and

cooling until the machine stops making grind

-

ing noises.

Note: The harder you press down on the

collet holder, the larger the back relief will

be.

6. Remove the collet holder and drill bit, rotate

them 180º, reinsert them into the trimming

area, and repeat Step 5.

Figure 24. Rear trimming hole center over

grinding wheel edge (cover removed for clarity).

8. Remove the bit from the collet holder.

To create a split point bit:

1. Follow Steps 1-7 for creating a back relief on

a standard bit.

2. Continue lowering the adjusting block, grind-

ing the drill bit on both sides, examining it,

and carefully adjusting the block down until

the back relief looks like the example in

Figure 22.

Be careful not to lower the adjusting block too

far, or the point may oversplit, as shown in

Figure 26.

Figure 25. Back relief on standard bit too small.

Back Relief

3. Remove the bit from the collet holder.

Figure 26. Oversplit point.

7. Remove the collet holder and examine the

bit.

— If the back relief matches the one in

Figure

21 you are finished.

Center

Wheel

Edge