-16-

H8203 Professional Drill Sharpening Machine

The Model H8203 allows you to select a specific

point angle based on the type of material to be

drilled. For general purpose use, such as wood

and soft metal, set the point angle to 118º (see

Figure

16). Set the point angle at 135º or 140º for

drilling harder workpieces such as stainless steel,

or 90º-100

º for drilling soft cast iron workpieces.

To adjust the point angle:

1. Determine the point angle of your bit.

—If you want to grind the same angle that is

already on your bit, match the bit with one

shown in

Figure 16.

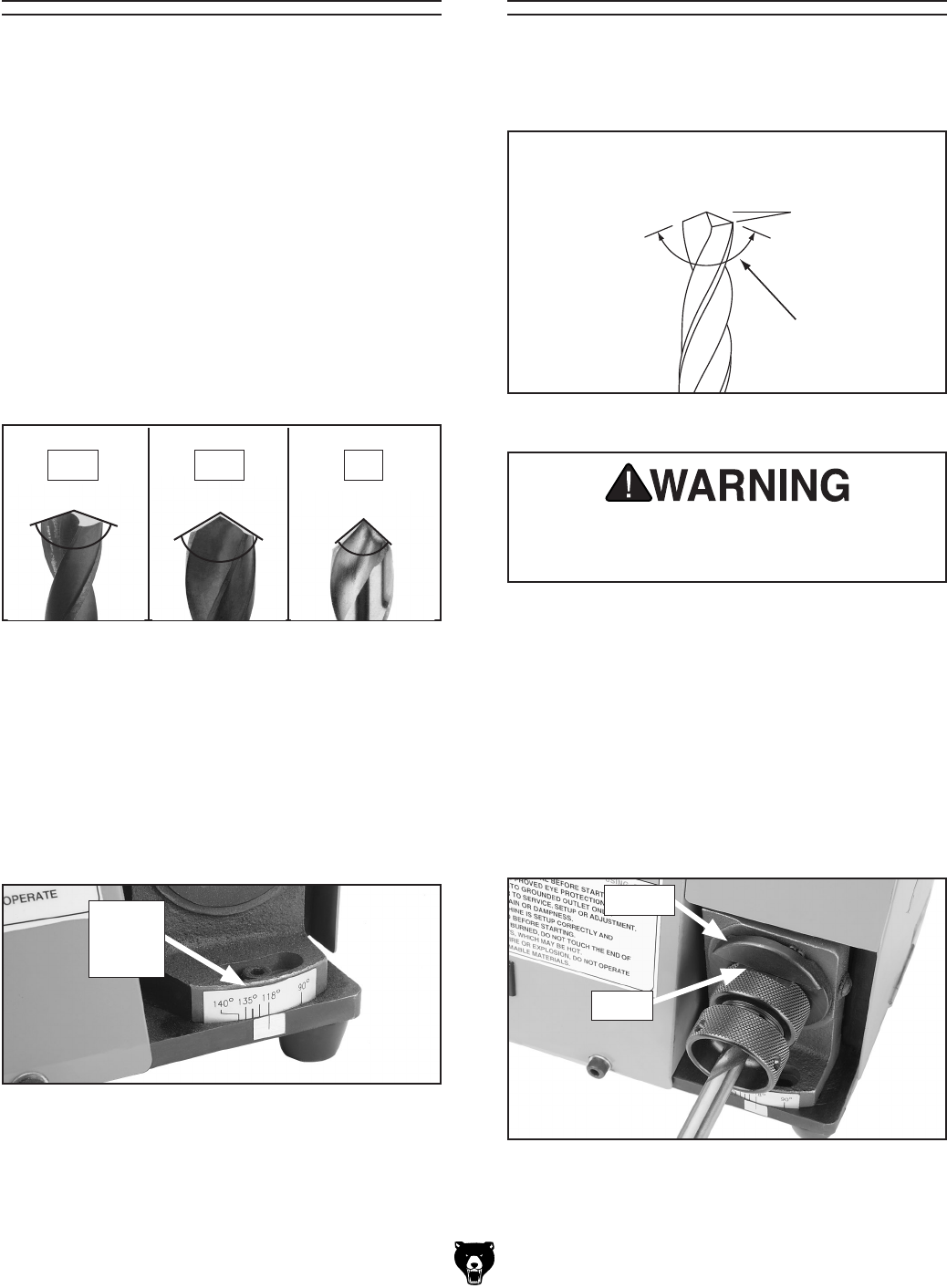

Figure 17. Point angle set to 118º.

Point

Angle

Scale

Setting Point Angle

Figure 16. Point angle examples.

—If you are not certain of the bit angle or

want to select a different point angle, base

the angle on the material softness or hard-

ness of your application.

2. Use the included hex wrench to loosen the

cap screw on the point angle scale (

Figure

17).

3. Turn the scale to the desired angle and tight-

en the cap screw.

118º135º 90º

Figure 19. Collet holder notch parallel to

grinding area flange.

Flange

Notch

Front Grinding Area

The grinding wheel adjusts the drill bit point angle

and taper relief angle in the front grinding area

(Figure 18).

To grind the point angle:

1. Make sure the grinding wheel cover is

secured, turn the machine

ON, and wait for

the machine to reach full speed.

2. Insert and rotate the collet holder into the

front grinding area so the notch on the collet

holder fits against the edge on the grinding

area flange, as shown in

Figure 19.

Figure 18. Drill bit point angle.

To reduce risk of fire or explosion from hot

metal or chips, do not operate machine near

flammable materials.