21

English

2. Dismounting the saw blade

Dismount the saw blade by reversing the mounting procedures described in paragraph 1 above.

The saw blade can easily be removed after lifting the cutter shaft guard.

CAUTION: Never attempt to install saw blades larger than 10" (255 mm) in diameter.

Always install saw blades that are 10" (255 mm) in diameter or less.

OVERLOAD PROTECTIVE DEVICE FOR POLY–V–BELT

The power of the motor is transmitted to the saw blade by a Poly–V–Belt. When the Poly–V–Belt becomes

overloaded, the overload protective devise cuts off the current to stop the motor.

In this case turn the switch off immediately and raise the handle to its initial position. Then turn the switch

on and after running the tool for 20 seconds without a load for cooling of the motor. Then start the cutting

operatinon. The Poly–V–Belt or the motor will be damaged if the overload protective device turns off

frequently.

CAUTION: When the overload protective device stops the motor, the motor will start by turning

the switch on after turning it off. When turning the switch on, make sure that the

saw blade is not halfway in the material.

MAINTENANCE AND INSPECTION

WARNING:To avoid an accident or personal injury, always confirm that the trigger switch is turned

OFF and the power plug has been disconnected from the receptacle before performing

any maintenance or inspection of this tool.

1. Inspecting the saw blade

Always replace the saw blade immediately upon the first sign of deterioration or damage.

A damaged saw blade can cause personal injury and a worn saw blade can cause ineffective operation

and possible overload to the motor.

CAUTION: Never use a dull saw blade. When a saw blade is dull, its resistance to the hand

pressure applied by the tool handle tends to increase, making it unsafe to operate

the power tool.

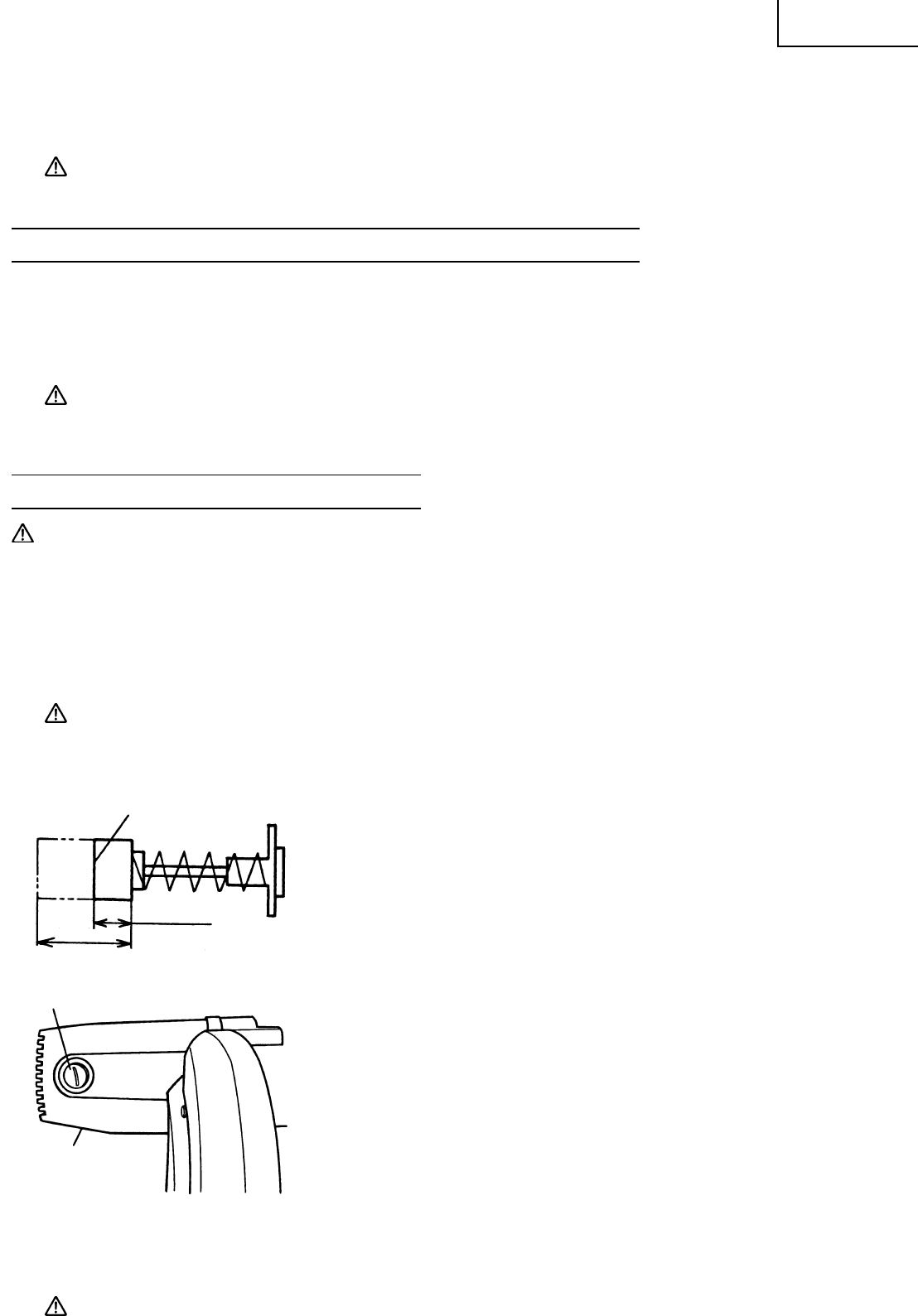

2. Inspecting the carbon brushes (Fig. 37 and Fig. 38)

The carbon brushes in the motor are expendable parts.

If the carbon brushes become excessively worn, motor trouble

might occur.

Therefore, inspect the carbon brushes periodically and replace

them. Check the carbon brushes after the first 50 hours of use for a

new machine or after a new set of carbon brush have been installed.

After the first check, examine them after each about 10 hours of

use until such time that replacement is necessary.

When the carbon on either brush is worn to 3/16" (5 mm) in length

or if either spring or shunt wire is burned or damaged in any way,

replace both carbon brushes (see Fig. 37). If the carbon brushes

are found serviceable after removing, reinstall them in the same

position as before removed.

Also, keep the carbon brushes clean so that they will slide smoothly

within the brush holders.

The carbon brushes can easily be removed after removal of the

brush caps (see Fig. 38) with a slotted (minus) screwdriver.

3. Inspecting the mounting screws

Regularly inspect each component of the power tool for looseness.

Re-tighten mounting screws on any loose part.

WARNING: To prevent personal injury, never operate the power tool if any components are loose.

Wear Limit Line

3/16" (5 mm)

43/64" (17mm)

Brush Cap

Motor Housing

Fig. 37

Fig. 38