-45-

Item Phenomenon Cause

Factory

standard

Inspection, repair or adjustment

2 Rough cut surface

Parallelism (A)= 0.02/43

(a) Large deflection of

saw blade.

(Causes rough cut

surface.)

0.15

/φ205

(Dummy disc)

• Same as Item 1- (b).

(b) Poor movement of

slide pipe section

prevents smooth

cutting.

Slide load should be

within 3 kgf.

• Apply machine oil to the slide

pipe section.

• Check the slide pipe section

for any scratches or the like.

• Repair as necessary.

• Readjust the Bushing [115].

(c) Excessive clearance

at the slide pipe

section.

-

• Readjust the Bushing [115].

• Replace Hinge (A) Ass’y [87],

or the Ball Bushing [114] as

necessary.

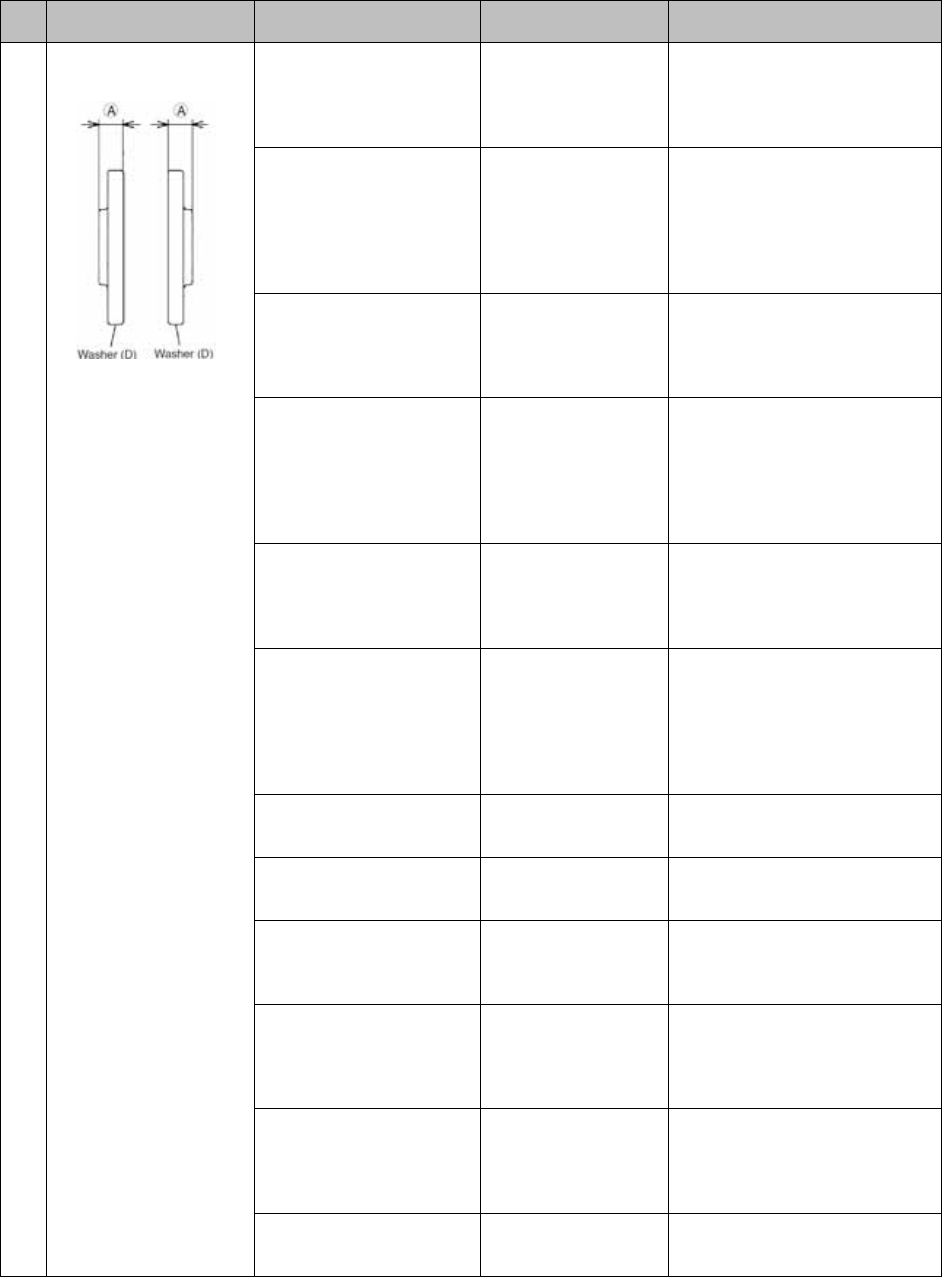

(d) Surface parallelism of

washers (D) is

inaccurate due to

surface defects such

as impact marks and

scratches.

0.02/43

(Fig. 64)

• Repair impact marks or

scratches at Washer (D) [221].

• Replace them if necessary.

(e) Improper slide cutting

technique.

- • See paragraph "Slide

Cutting." Do not apply

unnecessary force for

successful slide cutting.

(f) Inaccurate squareness

between turn table and

saw blade, causing

saw blade to cut at an

improper angle and

make cutting marks.

0.15/100

(Fig. 59)

• Same as Item 1- (a).

(g) Excessively fast

cutting speed.

- • Reduce cutting speed.

(h) Improper clamping of

workpiece.

- • Properly clamp workpiece with

Vise Ass’y [42].

(i) Turn table is not fixed

with side handle.

- • During cutting, fix the Turn

Table [13] in position with the

Side Handle [23] without fail.

(j) Loose fitting of

swiveling portion of

hinge and gear case,

or sluggish movement.

- • Same as Item 1- (h).

(k) Cutting operation

becomes sluggish

because workpiece is

warped or bent.

- • Correct warp or bend with

planer.

(l) Excessive vibration - • Recheck items (a), (c), (d) and

(i).

Fig. 64