-24-

1. Bevel angle adjustment

Before shipping from the factory, the height of 8-mm bolts (A) and (B) is adjusted so that the saw blade

section (head) will stop at 0° (right angle), and 45° to the left. To change the head stop positions, instruct

the customer to adjust the height of 8-mm bolts (A) and (B) by turning them.

CAUTION:

If there is any clearance between the tip of 8-mm bolt (A) (stopper for 0°) and the fixing pin, the

angle of the saw blade relative to the upper surface of the turn table may not be an exact right angle.

(8-mm bolts (A) and (B) are located at the holder (A).) Press down on holder (A) and lock it in

position with the clamp lever so that there is no clearance between the fixing pin and 8-mm bolt (A).

2. Ball bushing (Linear bearing)

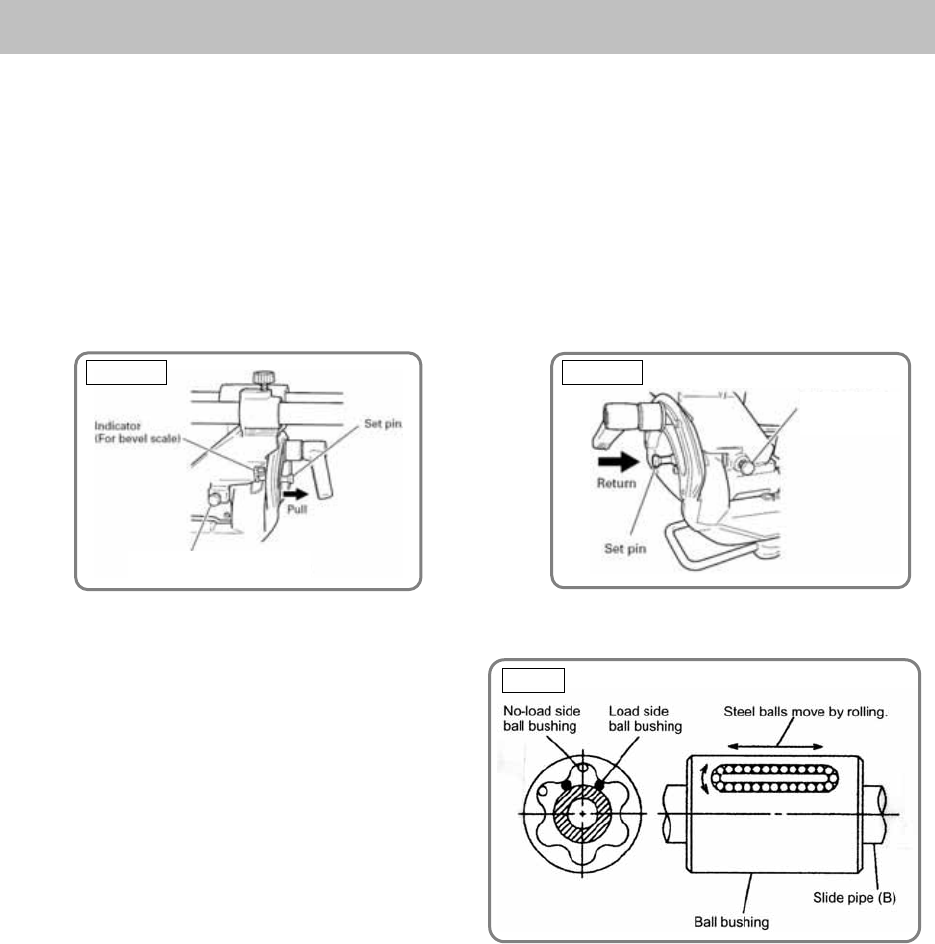

(1) Structure of the ball bushing

The ball bushing is commonly called a linear

ball bearing. Inside the bearing is elongated

guide grooves in which steel balls circulate

and roll when a load is applied. (as indicated

by the arrow marks in Fig. 34). This type of

device is widely used in automated machine

tools. The advantage of the ball bushing is

that its friction coefficient remains largely

unchanged even when the load is increased,

ensuring smooth sliding movement.

In addition, slide pipe (B), made of bearing steel and heat treated to a high degree of hardness (HRC 62

to 65), is highly resistant to wear.

Sales persons should have a good understanding of the structure and rugged characteristics of this

exceptional mechanism to enhance sales promotion.

(2) Lubrication

If it is necessary to replace the ball bushing, apply approximately 2 grams (0.1 oz) of grease (Nippeco

SEP 3A) on the steel balls and within the guide grooves of the new ball bushing. If grease is not applied,

it will shorten the service life of the ball bushing, and subsequent abrasive contact between the steel

balls and slide pipe (B) will cause abnormal noise during slide cutting operations. Customers should be

instructed to thoroughly remove sawdust and other foreign matter from slide pipe (A) and slide pipe (B)

and liberally coat them with machine oil at least once a month.

ADJUSTMENT OF COMPONENTS

Fig. 33-bFig. 33-a

Fig. 34

8 mm bolt (B)

(Stopper for left 45° bevel angle)

8 mm bolt (A)

(Stopper for 0°)