-40-

8. Adjustment of laser marker accuracy

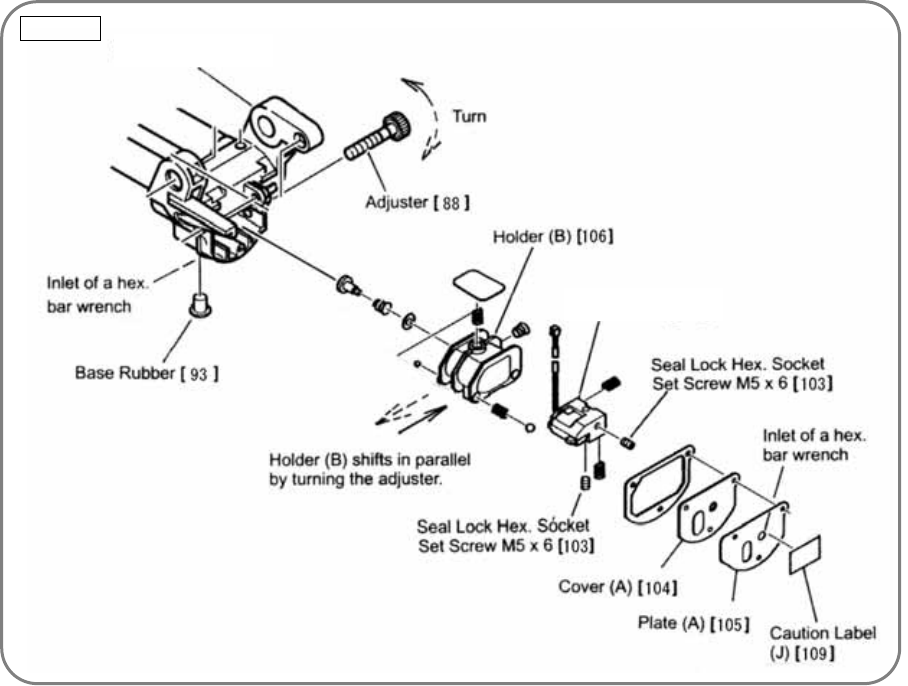

(1) Construction of laser marker and functions of each component

The Adjuster [88] located at the side of Hinge (A) Ass’y [87] is a screw used for moving the

Laser Marker [107] horizontally. The laser line can be aligned with the left side of the cutting width

(saw blade) or the ink line on the right side by means of the Adjuster [88]. The accuracy of the

Laser Marker [107] is adjusted by the two Seal Lock Hex. Socket Set Screws M5 x 6 [103].

The Seal Lock Hex. Socket Set Screw M5 x 6 [103] located at the front is mainly used for

adjusting the squareness with the fence surface.

The Seal Lock Hex. Socket Set Screw M5 x 6 [103] located under the Laser Marker [107] is mainly

used for adjusting the squareness with the base surface (Fig. 57-a).

The laser line will shift to the right in parallel when the Adjuster [88] is turned clockwise, and shift to

the left when turned counterclockwise.

CAUTION: Exercise utmost caution in handling the switch trigger for the position adjustment of

the laser line, as the power plug is plugged into the receptacle during operation.

If the switch trigger is pulled inadvertently, the saw blade can rotate and result in

unexpected accidents.

Do not stare into beam while the laser marker is lighting.

Do not observe beam directly with an optical instrument.

If your eye is exposed directly to the laser beam, it can be hurt.

Instruct the customer not to stare into beam. In addition, instruct the customer not to

give strong impact to the laser marker (main body of tool) and not to dismantle the laser

marker. Use of controls or adjustments or performance of procedures other than those

specified in this TECHNICAL DATA AND SERVICE MANUAL and the Instruction Manual

may result in hazardous radiation exposure.

Fig.55-a

Fig. 57-a

Laser Marker [107]

Hinge (A) Ass’y [87]