-44-

Item Phenomenon Cause

Factory

standard

Inspection, repair or adjustment

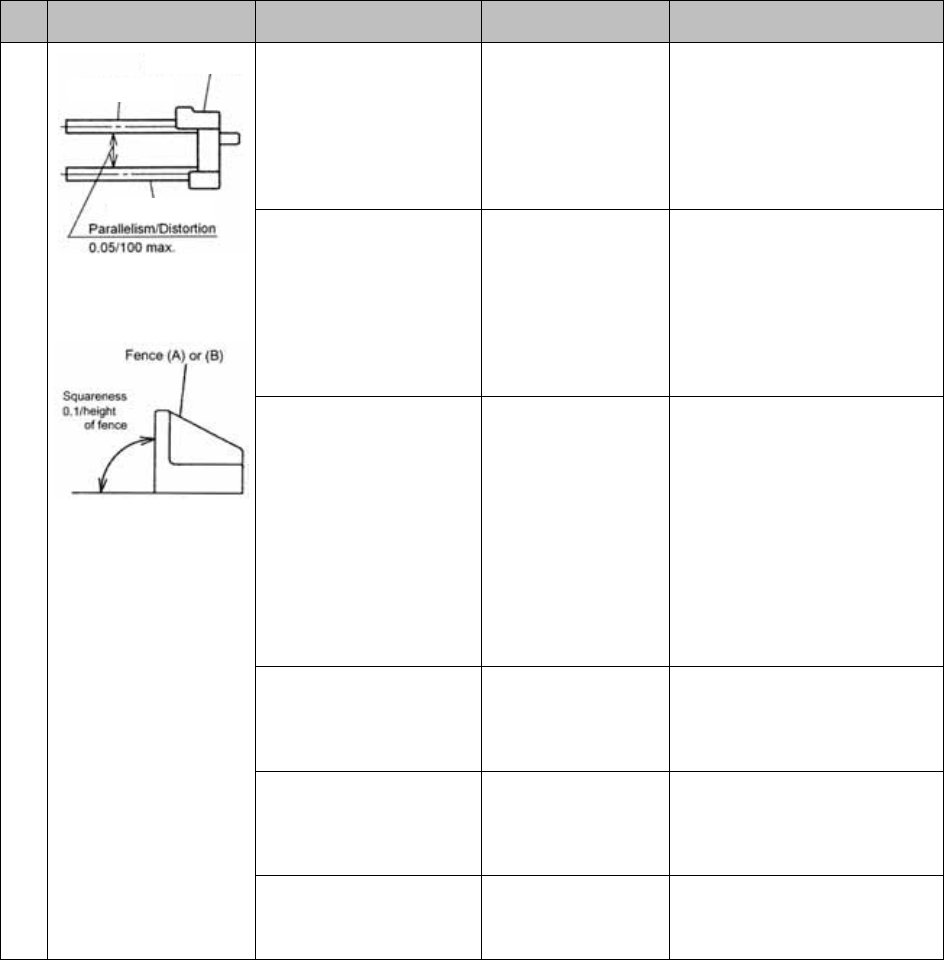

1 • Adjust the clearance between

the Bushing [115] and slide

pipe (A) with the Seal Lock

Hex. Socket Set Screw M6 x

10 [118]. Ensure that slide pipe

section slides smoothly with a

slide load of within 3 kgf.

(g) Inaccurate

squareness between

fences (A) and (B),

turn table and base

causes the workpiece

to tilt at an angle and

prevent accurate

cutting.

0.1/65

(height of Fence (A)

[55])

0.1/49

(height of Fence (B)

[47])

(Fig. 63)

• Replace Fence (A) [55] or

Fence (B) [47] as necessary.

(h) Loose fitting of

swiveling portion of

hinge (A) ass’y and

gear case, or sluggish

movement. As a result,

components may be

deformed because of

unstable gear case or

because the operator

must apply excessive

pressure during

operation.

- • Check the fitting surfaces of

Hinge (A) Ass’y [87], Gear

Case [198] and Hinge Shaft

(A) [92] for any foreign

substance (such as cutting

dust) and remove it as

necessary.

(i) Excessively fast cutting

speed causes

deflection of saw blade

and inaccurate cutting.

- • Reduce the cutting speed

(appropriately 6 seconds for a

square wood workpiece of 60

mm (2-3/8")).

(j) Excessive cutting force

(pressure) is required

because of dull saw

blade.

- • Sharpen the saw blade again.

(k) The workpiece moves

during cutting because

it is bent or deformed.

- • Correct bend, flex or other

deformation by planing and try

cutting.

Fig. 63

Fig. 62

Hinge (A) ass’y

Slide pipe (A)

Slide pipe (B)