-2-

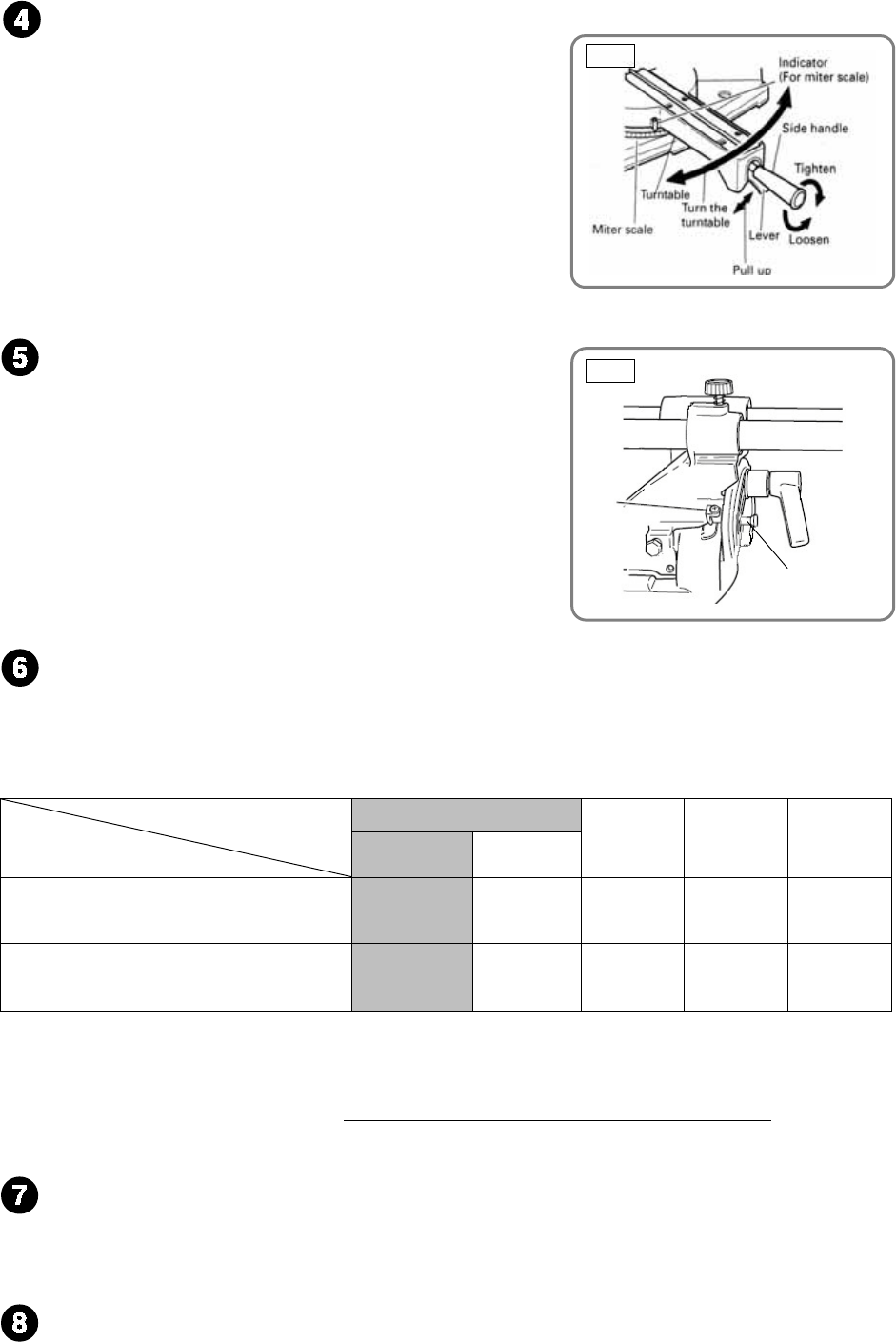

Positive angle stoppers

The Models C 8FSE and C 8FSHE have positive angle

stoppers in the turn table at the right and the left of the 0°

center setting, at 15°, 22.5°, 31.6° and 45° settings.

Thanks to the positive angle stoppers, positioning can be

done more securely than the ball index method utilized in

the current Model C 8FB2. In addition, a lever is provided

at the lower tip of the turn table to secure or release the

positive angle stoppers.

Adjustment of the turn table and positioning can be easily

done while holding the side handle.

Bevel cutting range: Left 48° to right 5°

Possible range of bevel cutting is from left 48 degrees to right 5

degrees. By the simple operation of the set pin, you can set the

position of the right angle and left 45 degrees.

In addition, setting to approximately 30 degrees and 33.9

degrees for crown molding cutting can be done by this set pin.

High dust collecting performance

The dust collecting performance of the Models C 8FSE and C 8FSHE are remarkably higher than the other

models thanks to the adoption of new dust guide and gear case.

HITACHI

C 8FSE

C 8FSHE

C 8FB2

P1 and P2 P3 B

Press cutting *

1

(Size of the workpiece:

60 mm x 60 mm (2-3/8” x 2-3/8”))

75.0 25.0 5.9 31.3 62.2

Slide cutting *

2

(Size of the workpiece:

30 mm x 150 mm (1-3/16” x 5-29/32”))

80.0 45.0 11.0 72.3 74.5

Soft grip handle

The handles are widely covered with soft-touch elastomer (rubber-like soft resin).

It is slip-resistant and securely fits in the palm of a hand even if the gripping hand sweats.

Legible scale

The Models C 8FSE and C 8FSHE have legibly labeled angle scale and bevel scale while the current

Model C 8FB2 has the scale printed on the die casting.

Table 1

(%)

Maker

Model

*1: This is a method to cut a workpiece by shaking the motor head.

*2: This is a method to cut a workpiece by sliding the motor head from the front.

The dust collecting performance is obtained from the following formula:

Weight of sawdust accumulated in the dust bag (g)

Weight of all sawdust during cutting (g)

Dust collecting performance (%) = x 100

Fig. 3

Set pin

Fig. 4

Cutting

method