-33-

Cross section viewed from the front

1. Special attention

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

(1) Prior to reassembly, measure the insulation

resistance of the armature, stator, switch and

other electrical components and confirm that

the insulation resistance of each part is more

than 5 MΩ.

(2) When replacing the Spring [85], apply 3 grams

of Hitachi Motor Grease to the inner

circumference of the new spring prior to

assembly.

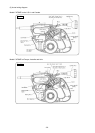

(3) When replacing or reassembling the Liner [54],

ensure that it is positioned and assembled as

illustrated in Fig. 46. In addition, coat 10 grams

of Hitachi Motor Grease on the liner sliding

portion of the Turn Table [13].

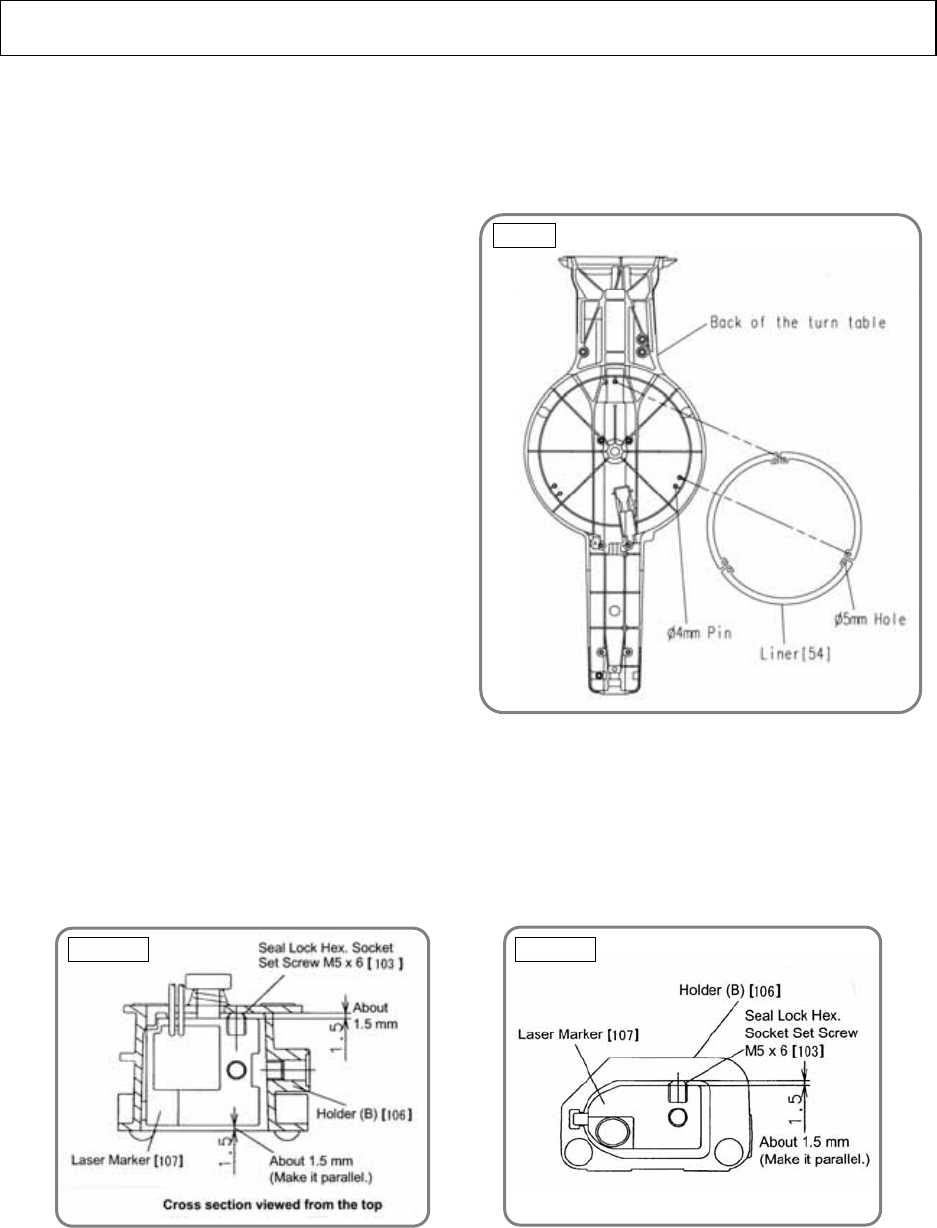

(4) When replacing the Laser Marker [107], screw the two Seal Lock Hex. Socket Set Screws M5 x 6 [103]

into the Laser Marker [107]. To adjust the accuracy of the Laser Marker [107] easily, protrude the tips of

the two Seal Lock Hex. Socket Set Screws M5 x 6 [103] about 1.5 mm from the Laser Marker [107]

using the 2.5-mm hex. bar wrench so that Holder (B) [106] and the Laser Marker [107] become almost

parallel as shown in Fig. 47-a and Fig. 47-b. Refer to "Adjustment of Laser Marker Accuracy" for

adjustment of the laser marker accuracy.

Reassembl

y

Fig. 47-a Fig. 47-b

Fig. 46