-43-

2. Troubleshooting guide

Item Phenomenon Cause

Factory

standard

Inspection, repair or adjustment

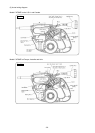

1 Inaccurate cutting

--- Inaccurate

squareness of the

cut surface

--- Cut surfaces do not

fit together properly.

(a) Inaccurate

squareness between

the turn table and the

saw blade causes the

saw blade to cut into

the workpiece at an

angle.

0.15/100

(Dummy disc)

(Fig. 59)

When sliding (tip)

0.25/100

(Dummy disc)

• Readjust squareness with the

Nylock Bolt M8 x 25 [123].

• Replace Hinge (A) Ass’y [87]

or Gear Case [198] or Turn

Table [13] or Base Ass’y [56]

(if deformed).

(b) Excessive deflection

of the saw blade

(Excessive vibration)

0.15

/φ205

(Dummy disc)

• Replace the TCT Saw Blade

[211].

• Check for surface defects on

Washer (D) [221] and repair

with a file as necessary.

• Replace Washers (D) [221].

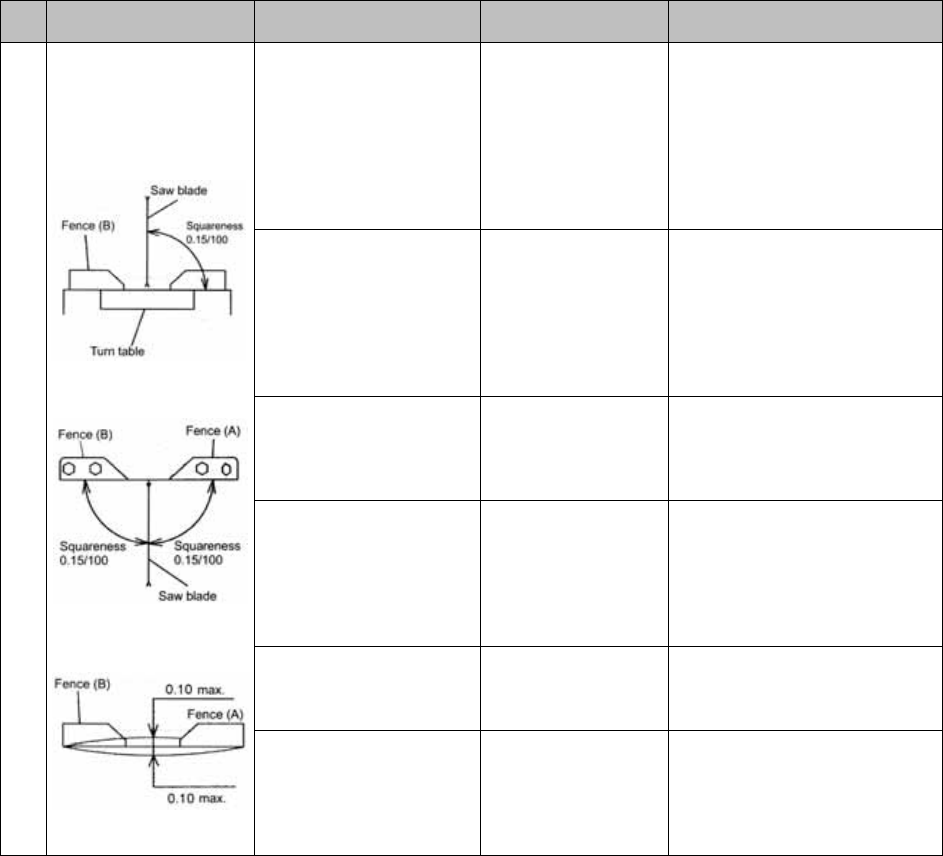

(c) Inaccurate

squareness between

fence (A) and fence

(B) and the saw blade

0.15/100

(Fig. 60)

• Loosen the Bolt M8 x 35 [43]

and adjust as necessary.

• Replace Fence (A) [55] and

Fence (B) [47].

(d) Surfaces of fence (A)

and fence (B) are not

accurately aligned,

causing workpiece to

deviate from proper

squareness.

0.10 or less

(Fig. 61)

• Loosen the Bolt M8 x 35 [43]

and adjust surface alignment

of Fence (A) [55] and Fence

(B) [47] as necessary.

• Replace Fence (A) [55] or

Fence (B) [47].

(e) Inaccurate surface

flatness of the turn

table.

0.15 or less

• Replace the Turn Table [13].

(f) Squareness between

the saw blade and the

turn table is changed

when sliding.

Same as (a)

(Fig. 62)

• Check precision after press-

fitting slide pipes (A) and (B)

of Hinge (A) Ass'y [87].

If precision is poor, replace

them as necessary. (Fig. 62)

Fig. 59

Fig. 60

Fig. 61