OM-356 Page 23

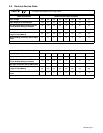

4-6. Start Mode

1 Start Mode

For SMAW welding, press button to toggle

LED to Off position.

For GTAW welding, use control to select Off

for no HF, Lift-Arct, HF for arc starting only,

or continuous HF. See Section 4-13 for ad-

justing high frequency intensity.

Application:

When Off is selected, use the scratch meth-

od to start an arc for both the SMAW and

GTAW processes.

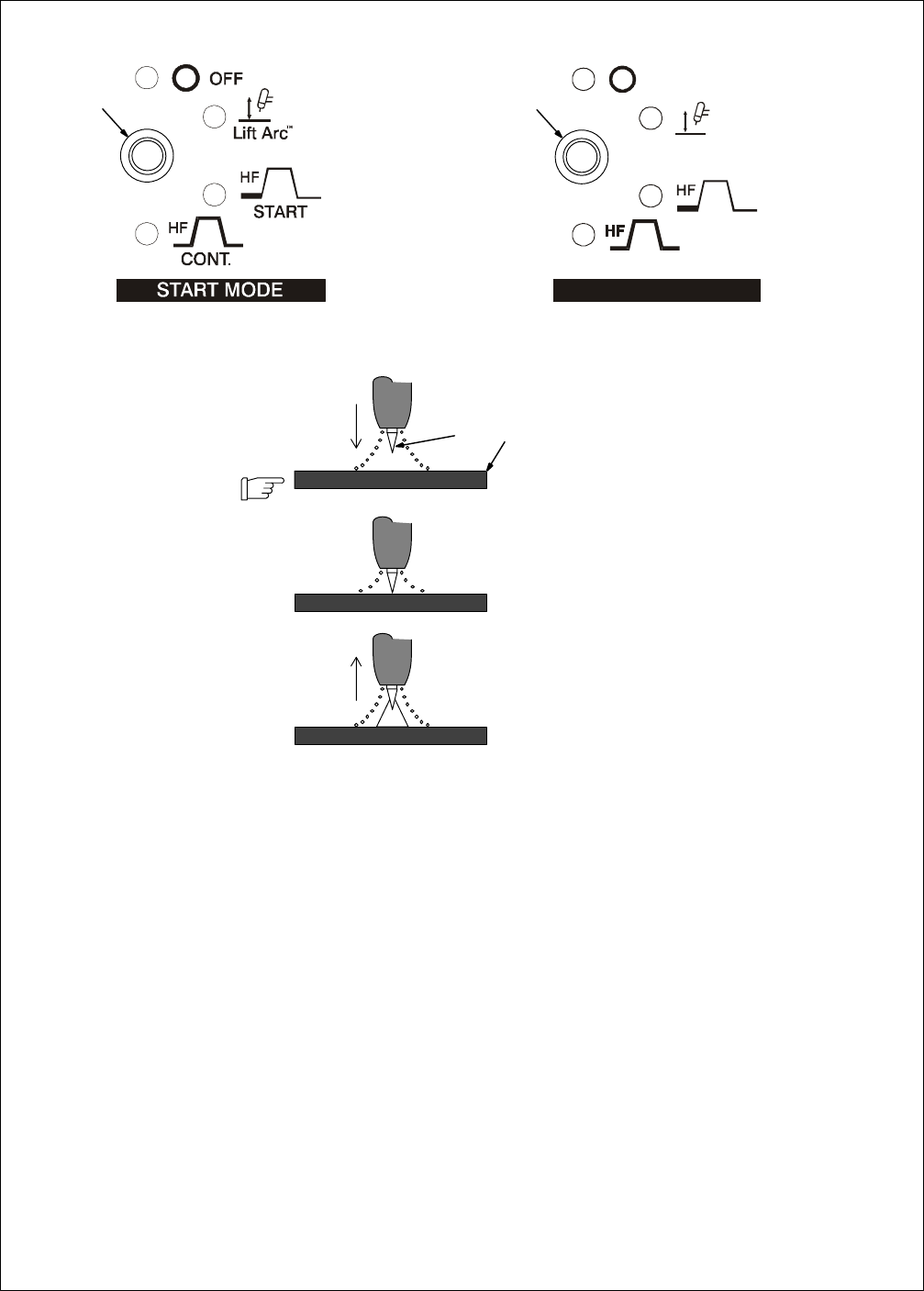

When Lift-Arc is selected, start arc as

follows:

2 TIG Electrode

3 Workpiece

Touch tungsten electrode to workpiece at

weld start point, enable output with torch

trigger, foot control, or hand control. Hold

electrode to workpiece for 1-2 seconds,

and slowly lift electrode. An arc will form

when electrode is lifted.

Shielding gas begins to flow when elec-

trode touches work piece.

Normal open-circuit voltage is not present

before tungsten electrode touches work-

piece; only a low sensing voltage is present

between electrode and workpiece. The sol-

id state output contactor does not energize

until after electrode is touching workpiece.

This allows electrode to touch workpiece

without overheating, sticking, or getting

contaminated.

Application:

Lift-Arc is used for the DCEN GTAW pro-

cess when HF Start method is not per-

mitted.

When HF Start is selected, start arc as

follows:

High frequency turns on to help start arc

when output is enabled. High frequency

turns off when arc is started, and turns on

whenever arc is broken to help restart arc.

Application:

HF Start is used when the DCEN GTAW

process is required.

When HF Continuous is selected, start

arc as follows:

High frequency turns on when output is en-

ergized and remains on for duration of weld.

Application:

HF Continuous is used when the AC GTAW

process is required.

NOTE: Lit LED indicates selected mode.

When Output Selector switch position

changes, LED may change position, based

upon last selection.

NOTE: Some start methods may not be

available for all processes.

1

2

1 – 2

Seconds

“Touch”

Do NOT Strike Like A Match!

3

Lift-Arct Start Method

1

(CE Nameplate Only)