17

Overview – Bearing Adjustments

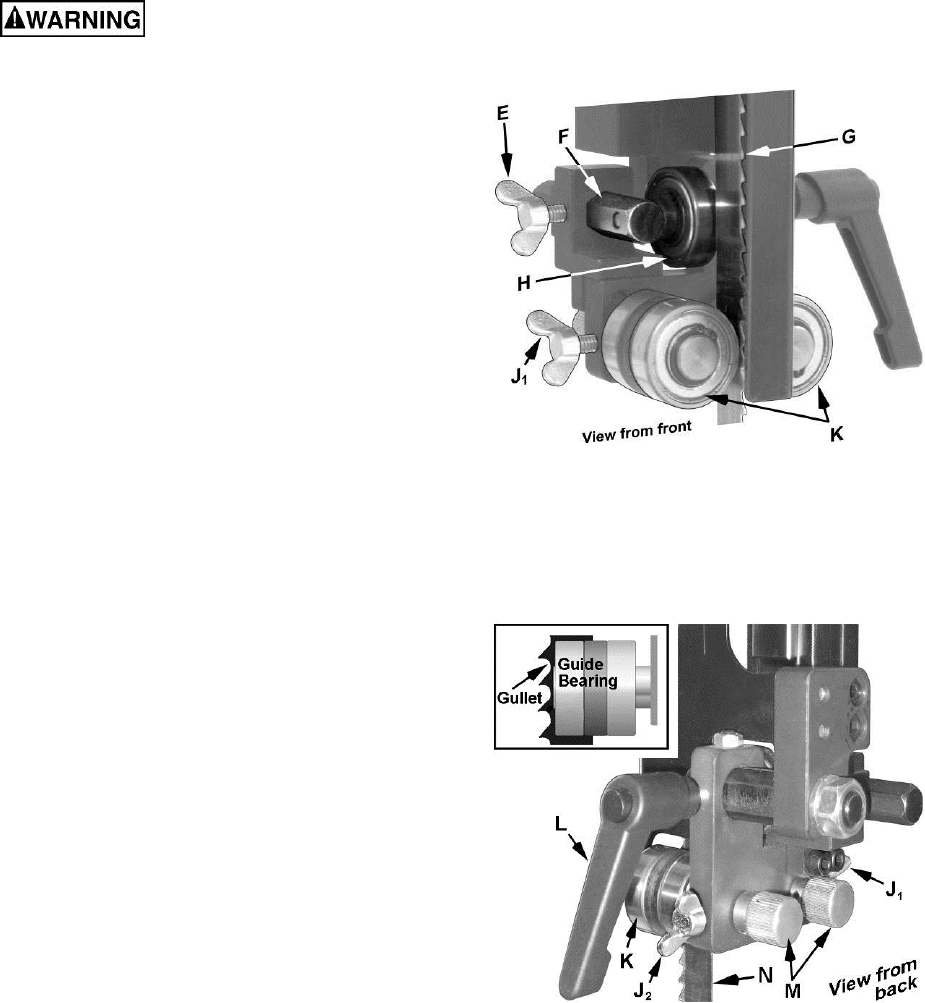

Thrust (back support) bearing are located behind

the saw blade and provide support to the back of

the blade when the saw is in operation.

Guide bearings are located on either side of the

saw blade and provide stability for the blade when

the saw is in operation. These bearings rotate on

an eccentric shaft so the distance from the blade

can be adjusted for optimal performance.

Upper Bearing Adjustments

Unplug the machine from power

source before making any adjustments! Blade

teeth are sharp - use care when working near

the saw blade. Failure to comply may cause

serious injury.

Note: Blade tension and tracking must be properly

adjusted prior to bearing guide setup. Refer to the

Blade Tension section (previous page).

To adjust the thrust bearing:

1. Place the mode selection lever (J, Fig. 18) in

the Full Tension position.

Referring to Figure 21:

2. Loosen the wing nut (E) and slide the bearing

and bearing post until the space between the

thrust bearing (H) and the back edge of the

blade (G) is approximately 1/64”.

A convenient way to achieve this spacing is by

placing a dollar bill folded twice (four

thicknesses) between the blade and support

bearing – four thicknesses of a dollar bill is

approximately 1/64”.

3. Tighten wing nut (E).

To adjust the guide bearings (refer to Figure 22):

4. Loosen the locking handle (L) and slide the

assembly until the front of the guide bearings

rest just behind the gullet of the blade teeth

(see inset).

5. Loosen two wing nuts (J

1

, J

2

). Rotate the

adjustment handles (M) until the guide bearings

(K) rest lightly against the blade (N). Do not

force the guide bearings against the side of the

blade.

6. Tighten wing nuts (J

1

, J

2

Fig. 22).

Check to make sure the adjustments have not

changed and the bearing guides do not pinch the

blade.

Place the mode selection lever (J, Fig. 18) in the

Partial Tension position when the machine is not in

use.

Figure 21

Figure 22