19

Blade Lead

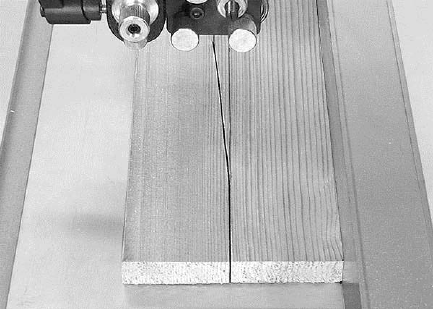

Blade drift (also known as lead or fence drift) is a

problem that may occur when the blade begins to

wander off the cutting line even when the band saw

fence is being used. Figure 24 shows an example

of blade lead.

Blade lead can be caused by a number of factors,

and these should all be checked and corrected if

necessary:

Fence is not parallel to miter slot and

blade.

Blade is not tensioned correctly.

Blade is dull.

Teeth have too much “set” on one side of

the blade.

If replacement of the blade is not currently an

option, the blade lead can be compensated for by

skewing the fence. Proceed as follows:

1. Cut a scrap piece of wood about the same

length as the band saw table, and joint one

edge along its length, or rip it on a table saw to

give it a straight edge.

2. Draw a line on the board parallel with the

jointed, or straight edge of the board.

3. Move the band saw fence out of the way, and

carefully make a freehand cut along your drawn

line on the board. Stop about midway on the

board, and shut off the band saw (allow the

blade to come to a complete stop) but do not

allow the board to move.

4. Clamp the board to the table.

5. Slide the band saw fence over against the

board until it contacts the straight edge of the

board at some point. Lock the fence down.

6. Loosen the four hex cap screws at the top of

the fence (see Figure 9) and shift the fence

until it is parallel to the board along its length.

7. Re-tighten the four hex cap screws.

Note: Skewing the fence to correct blade lead is

effective for that particular blade; when a new blade

is installed, the fence will probably need re-

adjustment.

Figure 24