B-7

OPERATION

B-7

BREAK-IN PERIOD

Any engine will use a small amount of oil during its

“break-in” period. For the diesel engine on the

RANGER 300, break-in is about 50 running hours.

Check the oil every four hours during break-in.

Change the oil after the first 50 hours of operation,

every 100 hours thereafter. Change the oil filter at the

second oil change.

During break-in, subject the RANGER 300 to moder-

ate loads. Avoid long periods running at idle. Before

stopping the engine, remove all loads and allow the

engine to cool several minutes.

------------------------------------------------------------------------

TABLE B.1

TYPICAL RANGER 300 FUEL CONSUMPTION

* DLX model only

WELDING OPERATION

The RANGER 300 machines can deliver from 45 to

300 amps of constant current for AC/DC stick welding.

The Ranger 300 DLX can deliver 45 to 300 amps of

constant voltage current for DC semiautomatic wire

feed welding. The Ranger 300 D can deliver 45 to

200 amps of constant voltage current for DC semiau-

tomatic wire feed welding. AC/DC constant current

TIG welding is possible across the entire range from

45 to 300 amps although 250 amps is the maximum

recommended for AC TIG welding of aluminum.

Output can be adjusted by setting the POLARITY

SWITCH, the OUTPUT RANGE dial, and the FINE

CONTROL dial on the output control panel to the set-

tings that are best for your selected welding process.

RANGER 300 D AND 300 DLX

CAUTION

Low Idle - No Load

2000 RPM

High Idle - No Load

3700 RPM

AC CC Weld Output

300 Amps @ 25 Volts

DC CC Weld Output

300 Amps @ 25 Volts

DC CV Weld Output

300 Amps @ 28 Volts*

Auxiliary Power,

12,000 kVA

.30 gallons/hour

(1.0 liters/hour)

.60 gallons/hour

(2.2 liters/hour)

1.1 gallons/hour

(4.2 liters/hour)

1.2 gallons/hour

(4.6 liters/hour)

.90 gallons/hour

(3.6 liters/hour)

1.3 gallons/hour

(4.9 liters/hour)

Do not attempt to use this equipment until you

have thoroughly read the engine manufacturer’s

manual supplied with your welder. It includes

important safety precautions, detailed engine

starting, operating and maintenance instructions,

and parts lists.

------------------------------------------------------------------------

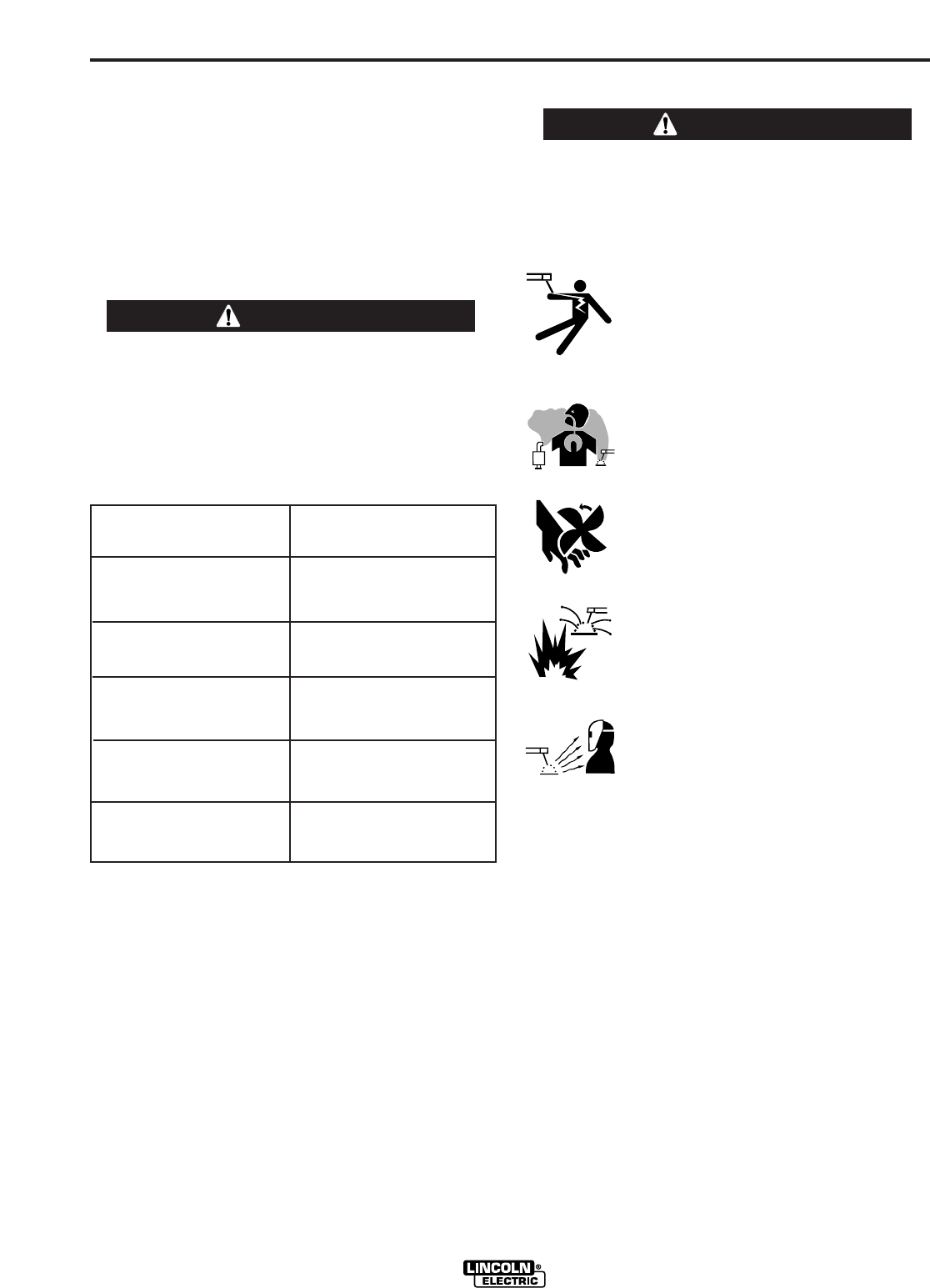

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground

• Always wear dry insulating gloves.

------------------------------------------------------------------------

FUMES AND GASES can be dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to remove

fumes from breathing zone.

------------------------------------------------------------------------

MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

• Keep away from moving parts.

------------------------------------------------------------------------

WELDING SPARKS can cause fire or

explosion.

• Keep flammable material away.

------------------------------------------------------------------------

ARC RAYS can burn.

• Wear eye, ear and body protection.

------------------------------------------------------------------------

See additional warning information

throughout this operator’s manual.

WARNING