E-3

TROUBLESHOOTING

E-3

RANGER 300 D AND 300 DLX

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

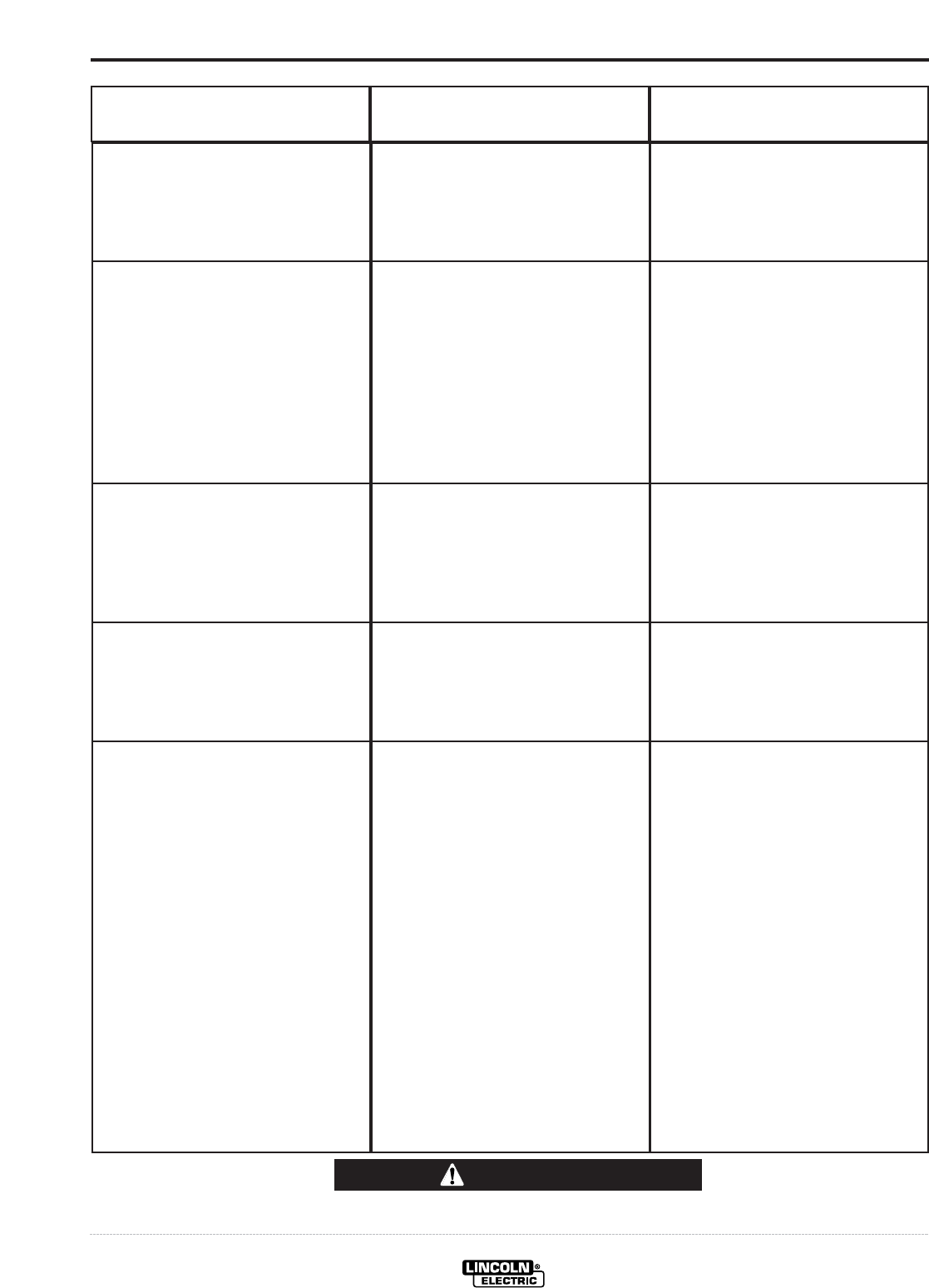

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

Engine will not idle down to low

speed.

Engine will not go to high idle when

attempting to weld.

Engine will not go to high idle when

using auxiliary power.

Engine will not go to high idle and

circuit breaker CB8 located in engine

compartment is open.

1. Idler switch in High idle position.

2. External load on welder or auxil-

iary power.

3. Faulty wiring or PC board.

1. Poor work lead connection to

work.

2. "Welding Terminals" switch is in

wrong position.

3. Faulty high speed solenoid or

faulty PC board.

1. Auxiliary power load is less than

100 watts.

2. Faulty high speed solenoid or

faulty PC board.

1. Faulty high speed solenoid

1. Set switch to Auto.

2. Remove all external loads.

3. Contact your Local Lincoln Authorized

Field Service Facility for technical

troubleshooting assistance.

1. Make sure work clamp is tightly con-

nected to clean base metal.

2. Set to "Always On" when welding with-

out a welding terminal control cable.

Refer to Operations chapter for proper

use of this switch.

3. Contact your Local Lincoln Authorized

Field Service Facility for technical

troubleshooting assistance.

1. Idler may not respond with less than a

100 watt load. Set idler to "High".

2. Contact your Local Lincoln Authorized

Field Service Facility for technical

troubleshooting assistance.

1. Reset CB8. If it continues to trip, con-

tact your Local Lincoln Authorized

Field Service Facility for technical

troubleshooting assistance.