)*,.#)(

1&#(!)(.,)&-

)/.*/.)(.,)&

The CONTROL dial provides continuous control of the

welding current or welding voltage depending on the

selected welding mode. This control is not active in the

CC-STICK, DOWN HILL PIPE, and CV-WIRE modes

when a remote control or wire feeder with remote con-

trol is connected to either the 6 pin or 14 pin Amphenol.

#!#.&)/.*/.'.,-

The digital meters allow the output voltage (CV-WIRE

mode) or current (CC-STICK, DOWN HILL PIPE and

TIG modes) to be set prior to welding using the OUT-

PUT control dial. During welding, the meter display the

actual output voltage (VOLTS) and current (AMPS). A

memory feature holds the display of both meters on for

seven seconds after welding is stopped. This allows the

operator to read the actual current and voltage just prior

to when welding was ceased. While the display is being

held the left-most decimal point in each display will be

flashing. The accuracy of the meters is +/- 3%.

1&')-&.),-1#."

(Provides four selectable welding modes)

CV-WIRE

DOWN HILL PIPE

CC-STICK

TOUCH START TIG

,)(.,)&

The ARC CONTROL WIRE/STICK dial is active in the WIRE,

STICK and DOWN HILL PIPE modes, and has different func-

tions in these modes. This control is not active in the TIG

mode.

CC-STICK mode: In this mode, the ARC CONTROL dial

sets the short circuit current (arc-force) during stick weld-

ing to adjust for a soft or crisp arc. Increasing the number

from -10 (soft) to +10(crisp) increases the short circuit

current and prevents sticking of the electrode to the plate

while welding. This can also increase spatter. It is recom-

mended that the ARC CONTROL be set to the minimum

number without electrode sticking. Start with a setting at

0.

DOWNHILL PIPE MODE: In this mode, the ARC CON-

TROL dial sets the short circuit current (arc force) dur-

ing stick welding to adjust for a soft or a more forceful

digging arc (crisp). Increasing the number from -

10(soft) to +10(crisp) increases the short circuit current

which results in a more forceful digging arc. Typically a

forceful digging arc is preferred for root and hot passes.

A softer arc is preferred for fill and cap passes where

weld puddle control and deposition (“stacking” of iron)

are key to fast travel speeds. It is recommended that

the ARC CONTROL be set initially at 0.

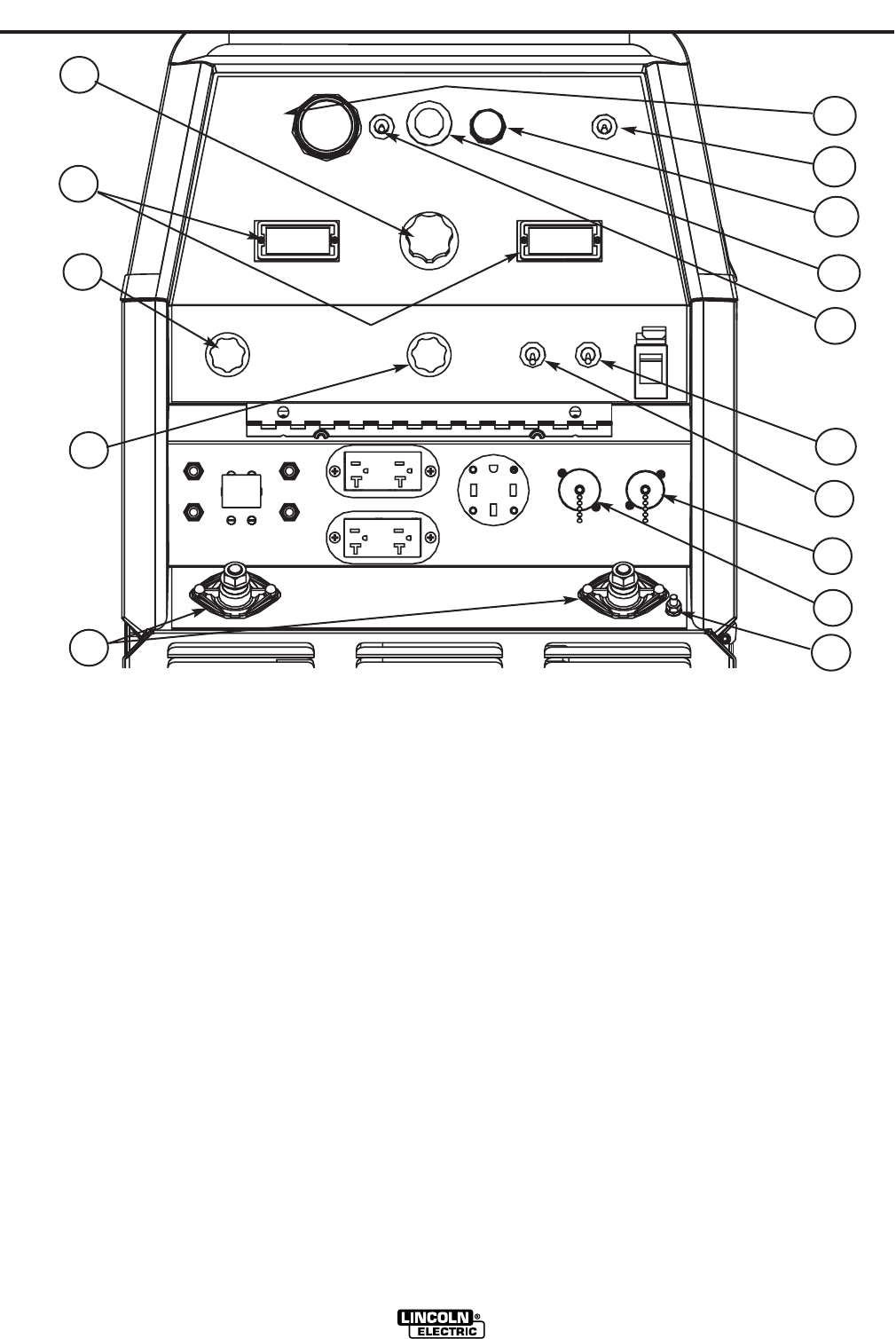

,(!,U&*!

1

10

7

4

9

5

8

11

12

13

6

15

14

2

3