)*,.#)(

)E:G6I>C<I=:HI6GI:GBDIDG;DGBDG:I=6CH:8

DC9H86C96B6<:I=:BDIDG#;I=::C<>C:;6>AHID

HI6GIG:A:6H:I=:HL>I8=6C9L6>IH:8DC9H

7:;DG:DE:G6I>DCI=:HI6GI:G6<6>CD().EJH=

I=:-.,.7JIIDCL=>A:I=::C<>C:>HGJCC>C<

7:86JH:I=>H86C96B6<:I=:G>C<<:6G6C9DGI=:

HI6GI:GBDIDG

------------------------------------------------------------------------

().: When starting a RANGER® 305LPG for the

first time, or after and extended period of time of not

operating, it will take longer than normal because the

fuel pump has to fill the fuel line and carburetor.

-.)**#(!

Remove all welding and auxiliary power loads and

allow the engine to run at low idle speed for a few min-

utes to cool the engine.

Stop the engine by placing the RUN-STOP in the

STOP position.

(). A fuel shut off valve is not required on the

RANGER® 305LPG because the fuel tank is mounted

below the engine.

1&,)*,.#)(

/.33&

Duty Cycle is the percentage of time the load is being

applied in a 10 minute period. For Example, a 60%

duty cycle represents 6 minutes of load and 4 minutes

of no load in a 10 minute period.

-.#%1&#(!

The RANGER® 305LPG can be used with a broad

range of DC stick electrodes.

The MODE switch provides two stick welding settings

as follows:

)(-.(. /,,(. -.#%

1&#(!

The CC-STICK position of the MODE switch is

designed for horizontal and vertical-up welding with all

types of electrodes, especially low hydrogen. The out-

put CONTROL dial adjusts the full output range for

stick welding.

The ARC CONTROL knob sets the short circuit current

during stick welding (arc-force). Increasing the number

from -10 to +10 increases the short circuit current and

prevents sticking of the electrode to the plate while

welding. This can also increase spatter. It is recom-

mended that the ARC CONTROL be set to the mini-

mum number without electrode sticking. Start with the

dial set at 0.

)1("#&&*#*1&#(!

This slope controlled setting is intended for "out-of-

position" and "down hill" pipe welding where the opera-

tor would like to control the current level by changing

the arc length. The output CONTROL dial adjusts the

full output range for pipe welding.

The ARC CONTROL knob sets the short circuit current

during stick welding (arc-force). Increasing the number

from -10 to +10 increases the short circuit current and

prevents sticking of the electrode to the plate while

welding. This can also increase spatter. It is recom-

mended that the ARC CONTROL be set to the mini-

mum number without electrode sticking. Start with the

dial set at 0.

,(!,U&*!

/.#)(

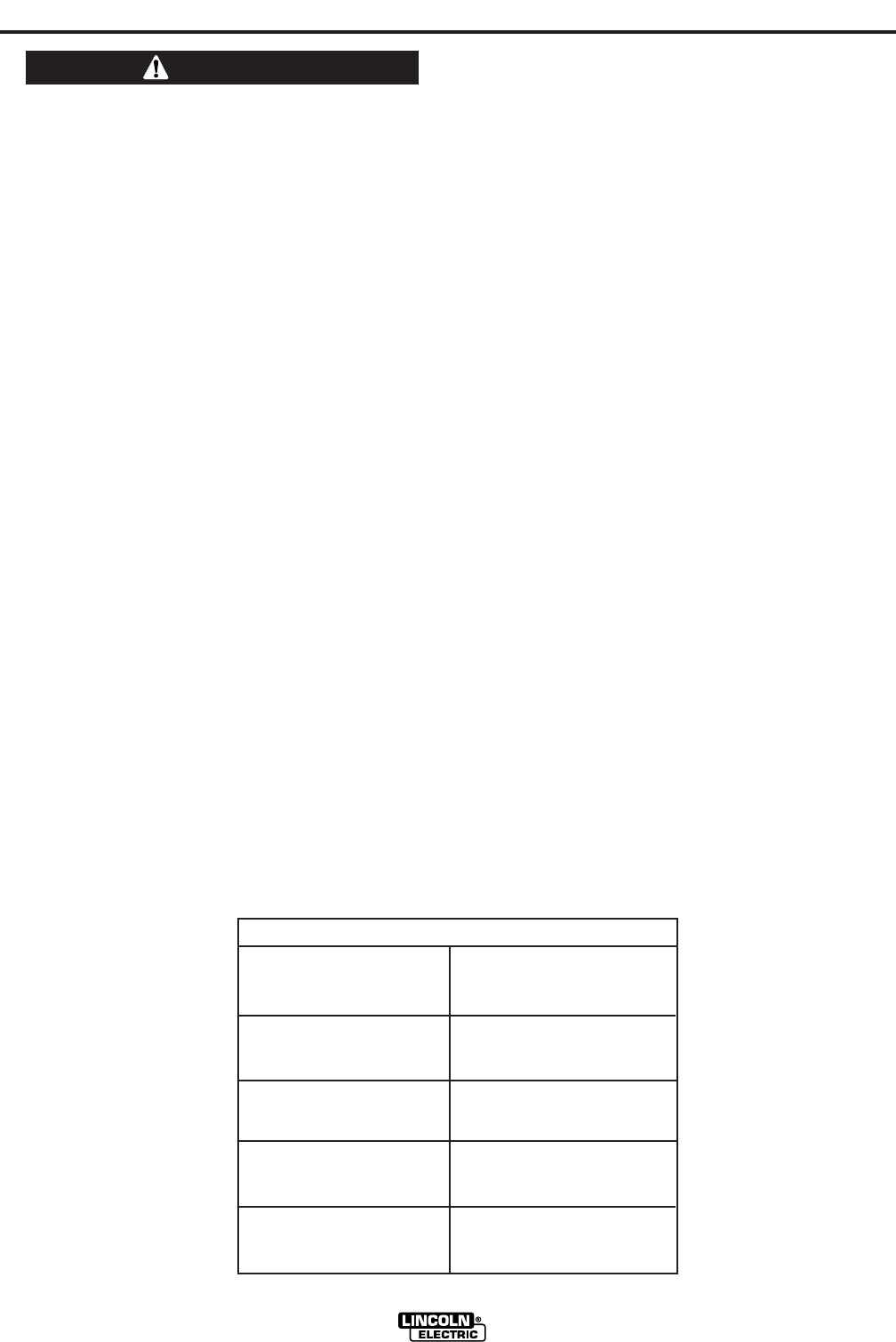

.3*#&,(!,U&*! /&)(-/'*.#)(

%D=A:G"

A7H=GH%<=G

&DL#9A:(D&D69

,*' 2.59 (1.17)

"><=#9A:(D&D69

,*' 4.58 (2.08)

1:A9)JIEJI

BEH0DAIH 8.80 (3.99)

JM>A>6GN*DL:G

16IIH 9.22 (4.18)