INSTALLATION

– 8 –

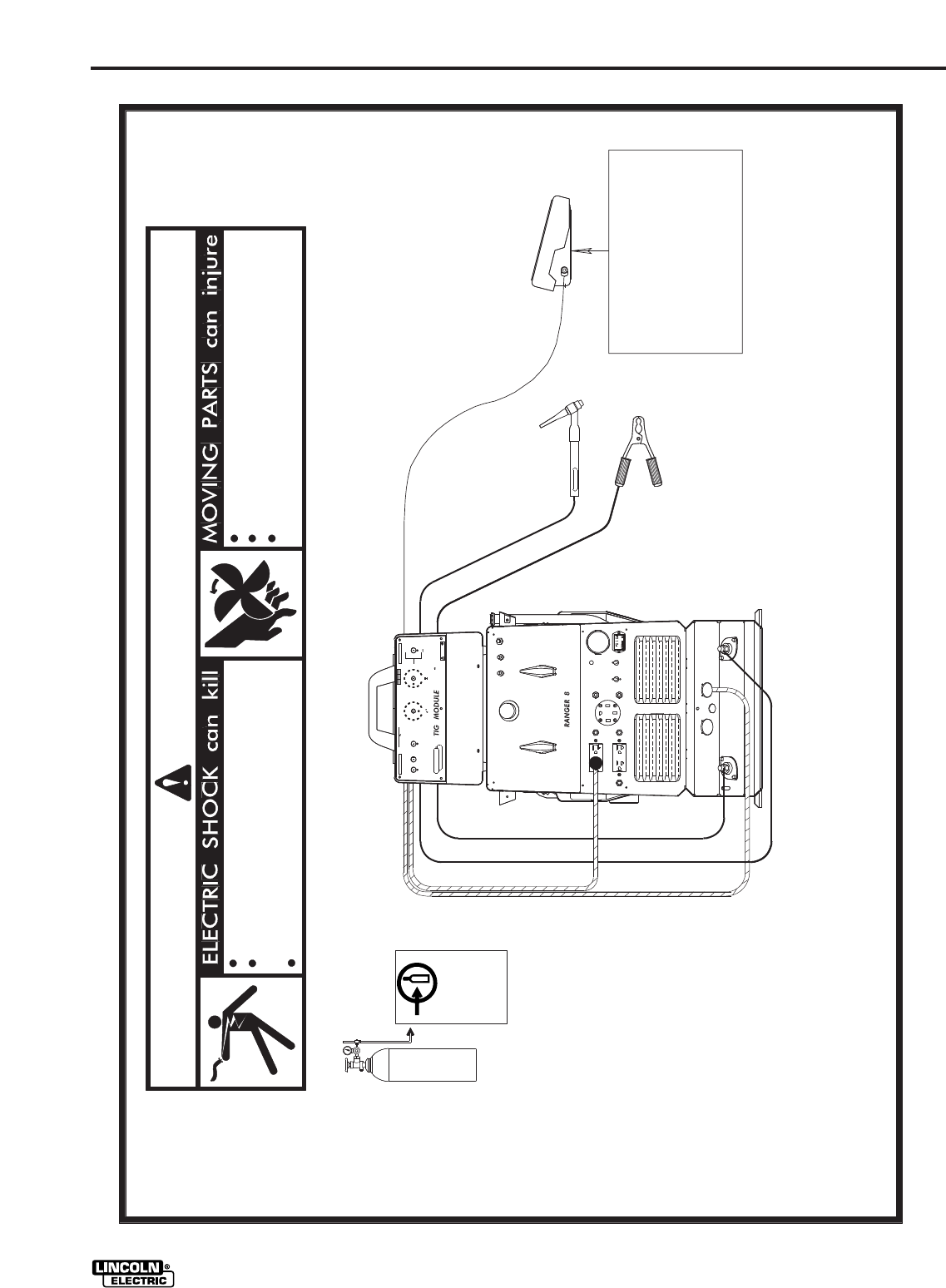

FIGURE 2: RANGER 8 / K892-1 REMOTE KIT / TIG MODULE CONNECTION DIAGRAM

5

10

15

20

25

30

35

40

45

50

55 S

CONTINUOUS

OFF

POWER

2

AFTERFLOW

MODEL

CODE

SERIAL NO.

THE LINCOLN ELECTRIC CO. CLEVELAND, OHIO U.S.A.

INPUT

PORTABLE HI-FREQ

WARNING

OFF

O

ON

L9

4

40

1

HIGH FREQUENCY

LOCAL

115 V 1.3 A 50/60 Hz

LINCOLN

R

ELECTRIC

0

1

2

3

4

5

6

7

8

9

10

CURRENT

CONTROL

SWITCH

TM

CURRENT CONTROL

REMOTE AMPTROL

HF

START ONLY

20%

350A

60%

100%

250A 180A

RATED CAPACITY

20A TO 350A

WARNING

Do not operate with panels open.

Disconnect NEGATIVE (-) BATTERY LEAD

before servicing.

Do not touch electrically live parts.

Keep guards in place.

Keep away from moving parts.

Only qualified personnel should install,use

or service this equipment.

5

10

15

20

25

30

35

40

45

50

55 S

CONTINUOUS

OFF

POWER

2

AFTERFLOW

MODEL

CODE

SERIAL NO.

THE LINCOLN ELECTRIC CO. CLEVELAND, OHIO U.S.A.

INPUT

PORTABLE HI-FREQ

WARNING

OFF

O

ON

L9

4

40

1

HIGH FREQUENCY

LOCAL

115 V 1.3 A 50/60 Hz

LINCOLN

R

ELECTRIC

0

1

2

3

4

5

6

7

8

9

10

CURRENT

CONTROL

SWITCH

TM

CURRENT CONTROL

REMOTE AMPTROL

HF

START ONLY

20%

350A

60%

100%

250A 180A

RATED CAPACITY

20A TO 350A

TO GAS

INPUT

FITTING

FLOWMETER

ARGON GAS

CYLINDER

K870 FOOT AMPTROL

-OR-

-OR-

K963 HAND AMPTROL

K814 ARC START SWITCH

M17531

4-19-96D

REGULATOR

WELDING CABLES MUST BE PROPERLY SIZED FOR THE CURRENT AND DUTY CYCLE OF APPLICATION

NOTE: This diagram is for reference only. It was accurate at the time of printing , however Lincoln Electric reserves the right to make improvements and modifications

as necessary, if you supect this information to be inaccurate, write to the Service Department for a replacement. Give the equipment code number..

TIG MODULE