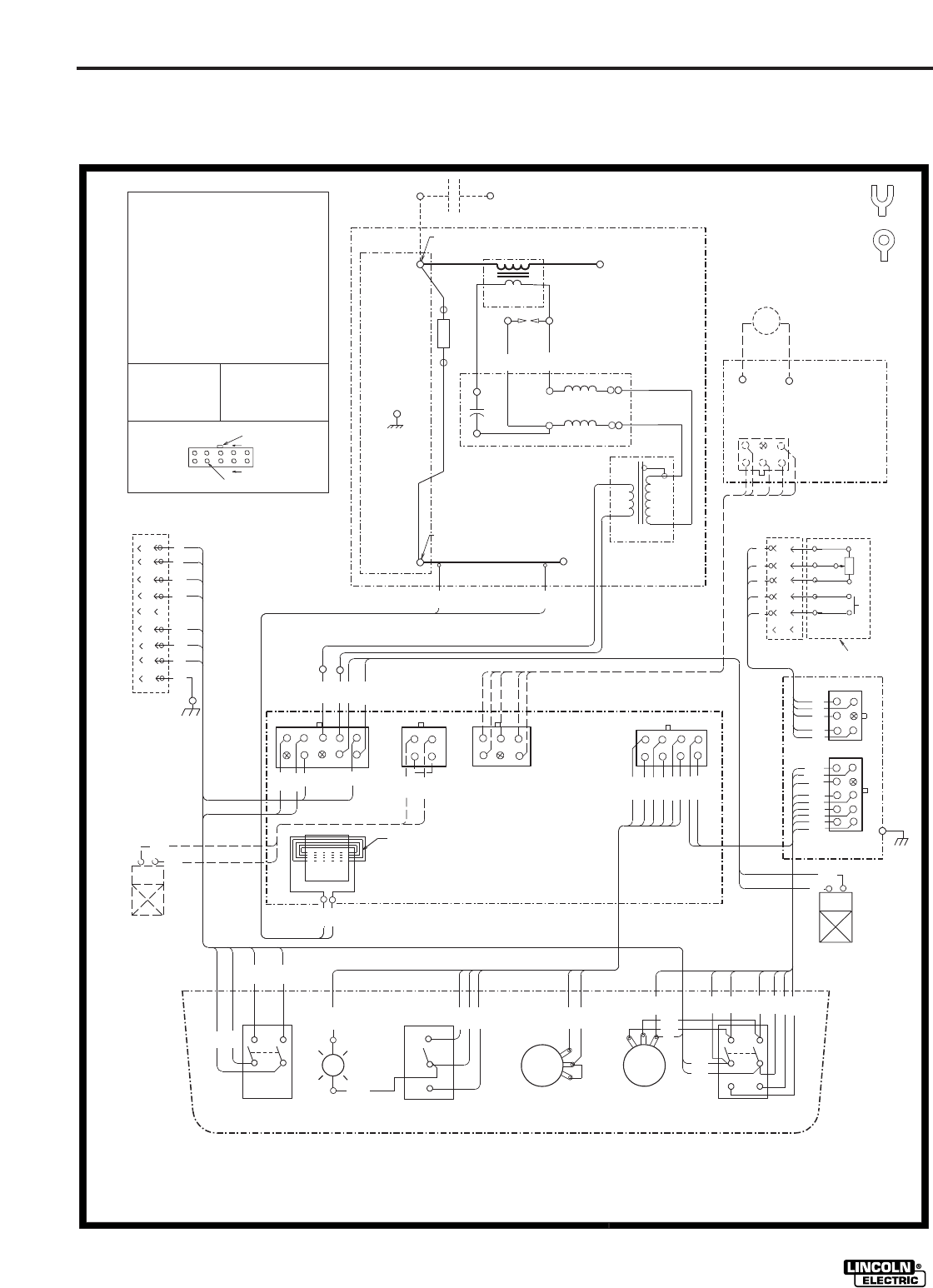

WIRING DIAGRAM

– 37 –

TIG MODULE

TIG MODULE

232

231

2

4

J2

302

I

403

76

403

404

301

H

231

232

S1

CONTROL BOARD

OFF

ONLY

START

404

75

206

+

205

210

CONTINUOUS

F

E

CURRENT SENSOR

G

77

G

311A

307

308

L9580

PROTECTION

BOARD

75

75A

76

209

LOCAL

208

CURRENT CONTROL

207

209

206

208

204

205

202

HIGH VOLTAGE TRANSFORMER

T1

OPTIONAL WATER SOLENOID VALVE

5

EXAMPLE: THIS PIN IN

SV2

CONNECTOR J1 IS "4J1"

GAS SOLENOID VALVE

SV1

CURRENT CONTROL SWITCH

S5

HIGH FREQUENCY SWITCH

S2

POWER SWITCH

B

C

D

SV2

POWER

OPTIONAL

WATER

SOLENOID

VALVE

32

31

4

PL1

RECEPTACLE

R2

FROM POWER SOURCE

AFTERFLOW

CONTROL PANEL

S2

( TILTED DOWN AND VIEWED FROM BACK )

HIGH FREQUENCY

77

PILOT LIGHT

274A

277A

1

CR1

BYPASS/

STABILIZER

C1

ELECTRICAL SYMBOLS PER

R- RED

N- BROWN

RESISTOR: OHMS/WATTS

E1537

U- BLUE

G- GREEN

CAPACITOR: MFD/VOLTS

W- WHITE

B- BLACK

COMPONENT VALUE UNITS:

LATCH

LEAD COLORING CODE:

CONNECTOR PIN NUMBERS:

6

WORK TERMINAL

10

HIGH FREQUENCY TRANSFORMER

T2

L1

BOARD

314

315

L2

SPARK

GAP

*

IF OPTIONAL CONTACTOR

IS CONNECTED

T2

TO TIG TORCH

311B

TO WORK

J3

PRI

*

*

*

CR1

REMOTE

RECEPTACLE

ELECTRODE TERMINAL

HIGH VOLTAGE CAPACITOR .0025/10KV

J1

2

PILOT LIGHT

HI-FREQ. INDUCTOR

AFTERFLOW TIME POTENTIOMETER 500K/2W

CURRENT CONTROL POTENTIOMETER 10K/2W

INPUT

A

CONTACTOR

J5

TM

BOARD

OPTIONAL

CONTACTOR

315 LUG =

314 LUG =

AND ARC START SWITCH

OPTIONAL REMOTE AMPTROL

C1

OPTIONAL CONTACTOR

PL1

R4

L1,L2

R3

S1

BLEEDER RESISTOR 150/100W

R2

CR1

FROM POWER SOURCE

4-19-96D

76A

275

75A

311B

311A

274

276

76A

277

77A

210

275

ELECTRODE TERMINAL

J4

T1

S

SEC

F

REAR

ASSEMBLY

2J3 CONNECTS TO 2J5, ETC.

NOTE: 1J3 CONNECTS TO 1J5,

A

B

C

D

E

FROM POWER SOURCE

204

77A

276

277

202

274

F

E

D

C

B

A

J22

AT MINIMUM

10K A-B

D

E

C

B

A

J23

302

301

REMOTE

S5

SV1

SWITCH

VALVE

GAS SOLENOID

CURRENT CONTROL

32

31

R4

ON

207

-

R3

R

206A

OFF

WIRING DIAGRAM FOR CODES 10135, 10203 and 10284

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diagram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. Give the equipment code number.