A-4

INSTALLATION

PRO-CUT 80

A-4

FRAME GROUNDING

The frame of the Pro-Cut 80 must be properly ground-

ed. A ground terminal marked is mounted on the

case bottom directly behind the input power switch for

this purpose. The cable that is sent attached to the

machine is connected to this ground terminal. See the

National Electric Code for details on proper grounding

methods. Install in accordance with all local and

national electrical codes.

INPUT VOLTAGE RECONNECTION

PROCEDURE

When changing input voltages, it is necessary to

change the settings behind the access door on the

side of the machine. Failure to do so may result in

damage to the machine.

To reconnect the Pro-Cut, follow the directions as out-

lined below. Follow this procedure ONLY while the

Pro-Cut is disconnected from the input power and the

capacitors have properly discharged.

1. Open the access door on the back of the machine.

2. For 200 to 230 : Position the large switch to 200-230.

For 400 to 460 : Position the large switch to 400-460.

For 550 to 575 : Position the large switch to 550-575.

3. Move the "A" lead to the appropriate terminal.

USE ON ENGINE DRIVEN POWER SUPPLIES

The Pro-Cut 80 can be used on engine driven power

supplies. However, the following AC Wave Form

Voltage and Input Power Restrictions do apply.

AC Wave Form Restrictions

The Pro-Cut 80 can be operated on engine driven

generators as long as the engine drive output meets

the following conditions:

The AC wave form frequency is between 45 and 65

Hz.

For 200 - 230 VAC Supplies:

The AC wave form peak voltage must be below 420

volts.

The RMS voltage must be 230VAC +/- 15%.

* The 230 VAC auxiliaries of Lincoln engine drives

meet these conditions when run in the high idle

mode.

For 380 - 415 VAC Supplies:

The AC wave form peak voltage must be below 840

volts.

The RMS voltage must be 400 VAC +/- 10%.

For 460 VAC Supplies:

The AC wave form peak voltage must be below 840

volts.

The RMS voltage of the AC wave form must be 460

VAC +/- 10%.

Input Power Restrictions

The available output current of the Pro-Cut 80 may be

limited due to the output capacity of the engine driven

power supply. The following are recommended output

current settings when used with various Lincoln

engine driven power supplies.

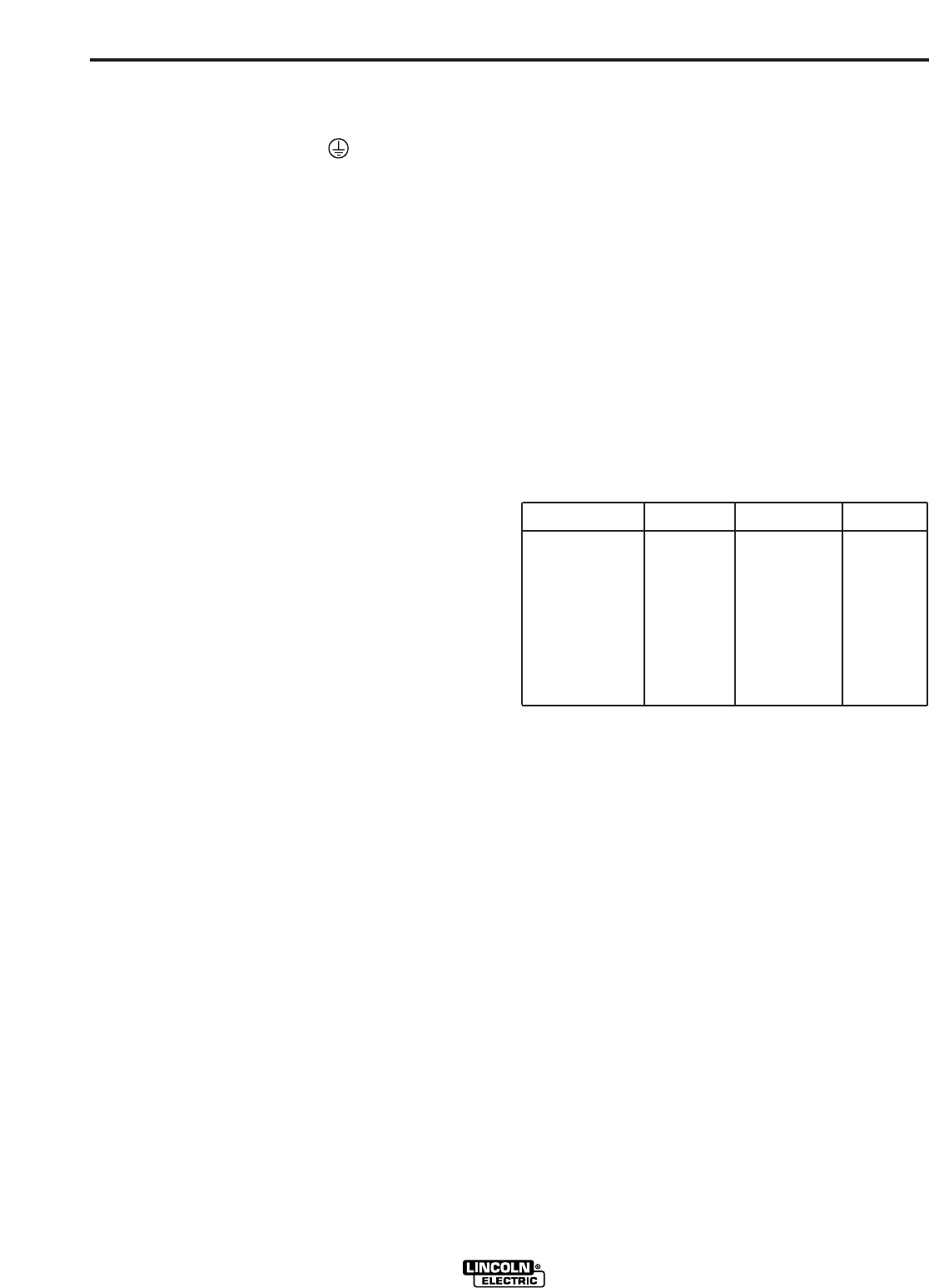

Engine Drive Auxiliary Power Pro-Cut 80 Output Cut Thickness

RANGER 8 8KW 30 Amps 5/16”

RANGER 9 9KW 40 Amps 3/8”

GX271 8KW 30 Amps 5/16”

RANGER 275 9KW 40 Amps 3/8”

RANGER 250 8.5KW 35 Amps 5/16”

RANGER 300D 12KW 55 Amps 5/8”

RANGER 305G 9.5KW 40 Amps 3/8”

RANGER 305D 9.5KW 40 Amps 3/8”

COMMANDER 300 10KW 45 Amps 1/2”

COMMANDER 400 10K 45 Amps 1/2”

COMMANDER 500 12KW 55 Amps 5/8”

VANTAGE 500 12KW 55 Amps 5/8”