E-7

TROUBLESHOOTING

E-7

PRO-CUT 55

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

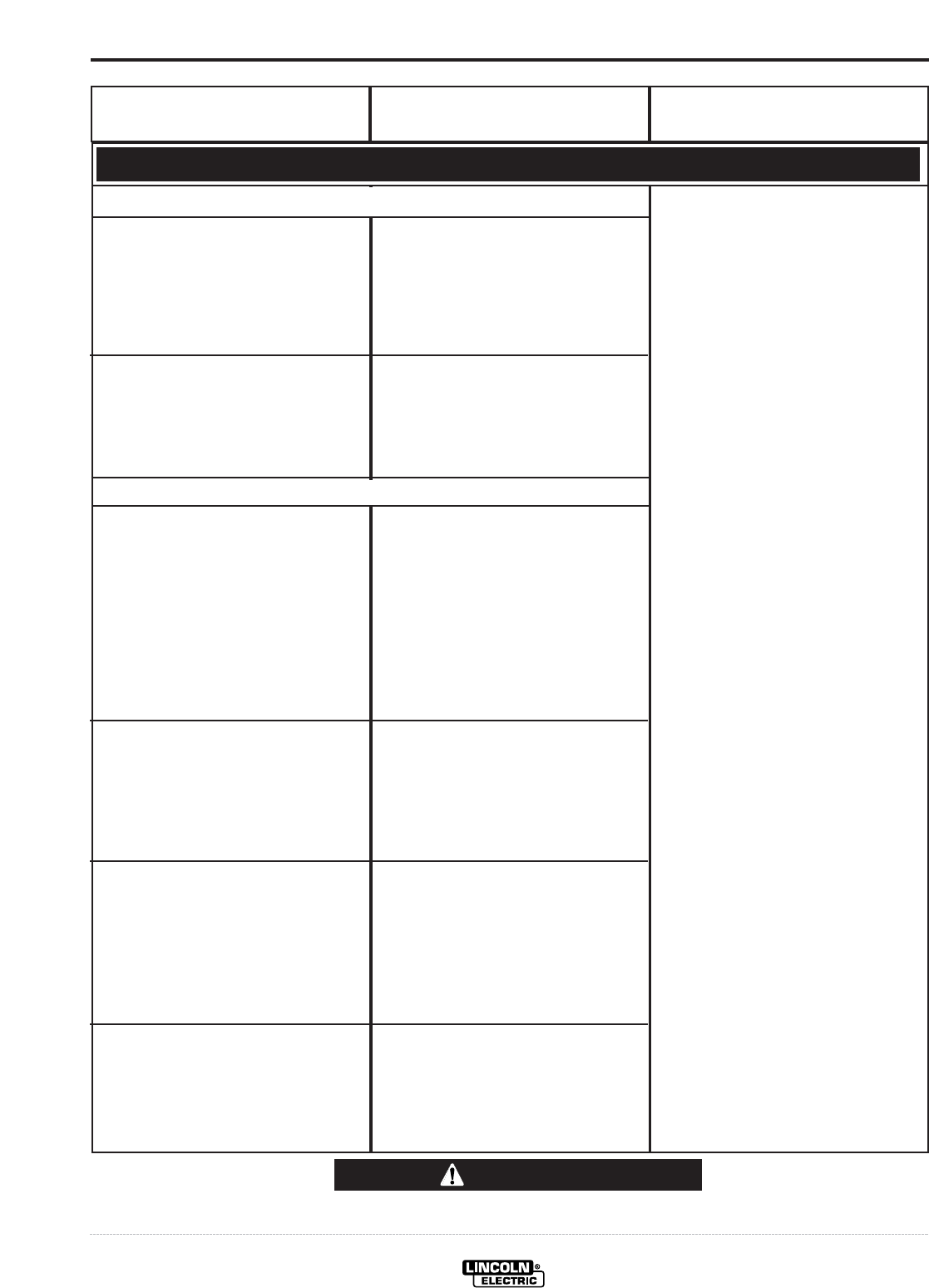

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

Press the reset button. If the torch

and consumables are properly

installed, the Safety LED should turn

off.

Try to recount the number of times

that the Safety LED has come on lit

and steady with this particular set of

consumables.

Check the condition of the electrode.

The maximum wear depth in the

center of the electrode tip is approxi-

mately .060" relative to the surround-

ing tip. A green and erratic arc will

indicate definite electrode failure as

explained in the "Consumable Life"

section of this manual.

Check the conditions of the inside of

the nozzle. Make sure that both the

electrode and nozzle are not dirty,

oily, or corroded.

Remove consumables from torch

and check inside of torch head for

contamination. Check incoming air-

flow for contaminants.

Make sure there is a Lincoln PCT 80

torch connected properly to the Pro-

Cut 55 and that the consumables are

properly installed. Make sure the

shield cup is hand tight. Do not use pli-

ers or over-tighten.

1. If the reset button (when pressed)

does not turn the Safety LED off,

the reset button or associated

wiring may be faulty. See the

wiring diagram.

1. If this has occurred numerous

times, clean consumables with a

piece of fine emery cloth to

remove any oxide buildup on the

tip of the electrode, or try replac-

ing the electrode and nozzle.

1. Replace both electrode and noz-

zle if electrode is excessively

worn. Otherwise, use a piece of

fine emery cloth to remove any

oxide buildup on the tip of the

electrode. Even if consumables

appear to be in good working

order, it is possible that they are

the cause of the problem. Try

replacing.

1. If debris has collected, rub the

electrode on the inside bottom of

the nozzle to remove any oxide

layer that may have built up. If

problems persist, try replacing

consumables.

1. If torch head is contaminated, take

a dry cotton swab and clean out

the pollutants. If needed, replace

air filter and check/change air sup-

ply. For more information, refer to

the "Gas Input Connections" sec-

tion in the manual.

1. After verifying that the torch and

consumables are properly set in

place, and the problem still per-

sists, contact your local Lincoln

Authorized Field Service Facility.

If all recommended possible areas of

misadjustment have been checked

and the problem persists, Contact

your local Lincoln Authorized

Field Service Facility.

NOTE: Make sure that consumables

are Lincoln Electric brand consum-

able parts. These parts are patented

and using any other replacement

consumables may cause damage to

the torch or reduce cut quality. Also

be sure to check that the nozzle is

the correct part number (as identified

on the top and side of the nozzle) for

the Pro-Cut being used.

CONSUMABLE RELATED SAFETY LED

If the Safety LED is LIT AND STEADY, perform the following:

If the Safety LED is FLASHING, perform the following: