B-3

OPERATION

B-3

CUTTING CAPABILITY

The PRO-CUT 80 is rated at 80 amps, at 60% duty cycle on a 10 minute basis (runs 80 amps for 6 minutes, then

idling for 4 minutes) or 60 amps, at 100% duty cycle (continuous use). If the duty cycle is exceeded, a thermal

protector will shut off the output of the machine until it cools to the normal operating temperature.

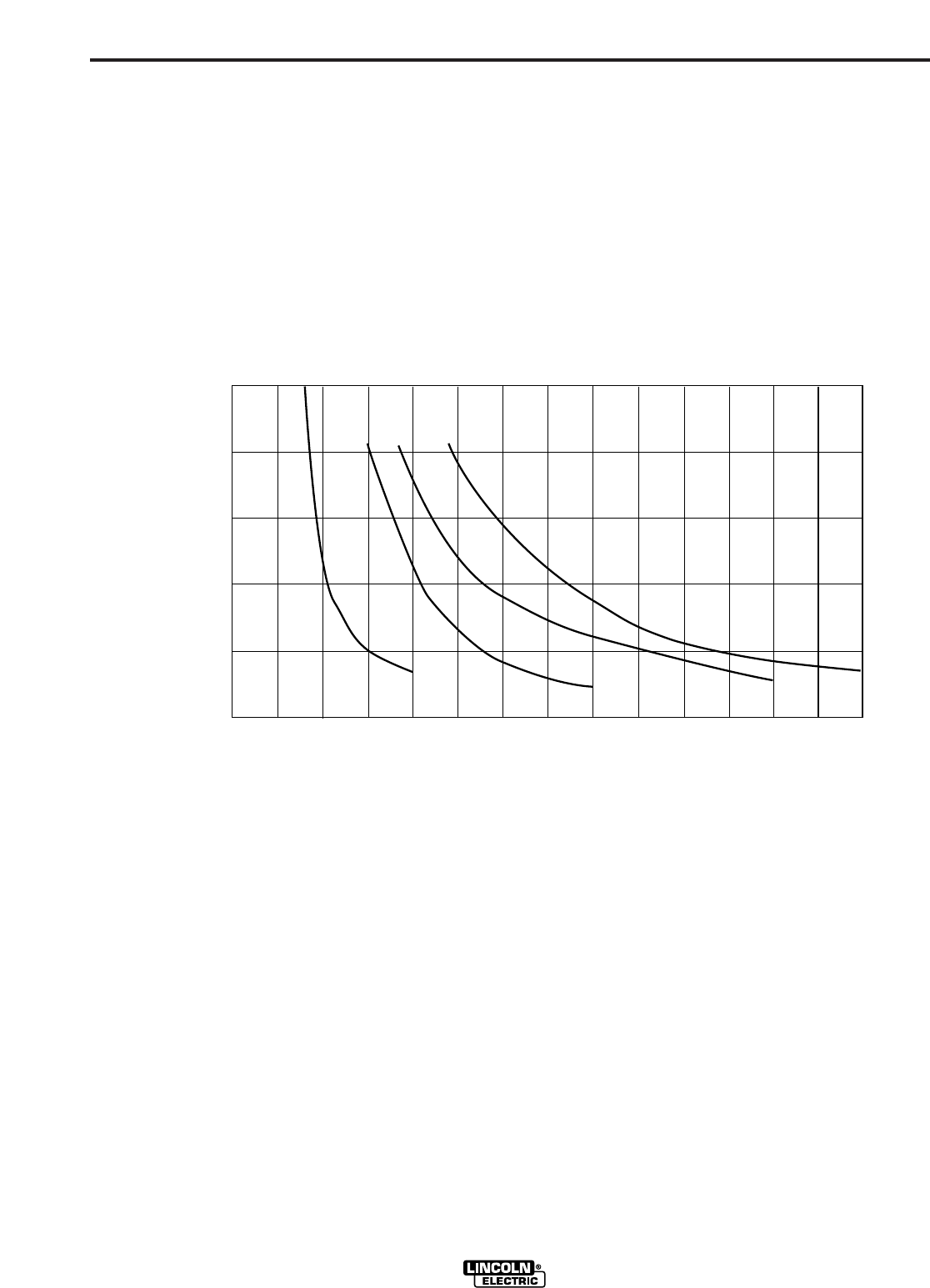

Figure B.1 shows the cut capacity of the PRO-CUT 80 when cutting mild steel. The graph plots cut thickness vs.

torch travel speed with a torch standoff of 0.15"(3.8mm). Example: 0.5”(12.7mm) material may be cut at a setting

of 55 amps at an approximate speed of 25”/m(635mm/m) or at a setting of 80 amps at an approximate speed of

35”/m(889mm/m).

PRO-CUT 80

Lincoln’s PRO-CUT 80

Mild Steel Cut Capacity Chart

Recommended Torch Travel Speed (IPM)(mm/m)

80% of Maximum Speed

100

2540

2032

80

1524

60

40

1016

20

508

0

0.000 0.125

(3.2mm)

0.250

(6.4mm)

0.375

(9.5mm)

0.500

(12.7mm)

0.625

(15.9mm)

0.750

(19.1mm)

25 A

35 A

55 A

1.00

(25.4mm)

80 A

Figure B.1

CONSUMABLE LIFE

The expected life for the PRO-CUT 80’s electrode under normal conditions is approximately 30 to 40 minutes of

cutting time at the machine’s maximum rated output. An erosion of approximately 1/16" in the electrode tip is typ-

ical for the end of electrode life, however, the electrode may last longer. A sustained green and erratic arc will

indicate definite electrode failure and both the electrode and nozzle should be replaced immediately.

It is recommended that consumables (electrode and nozzle) be replaced in complete sets. This will maximize the

performance of the PRO-CUT system.