F-62

TROUBLESHOOTING & REPAIR

F-62

2. Check for the proper wire feed inch-

es per revolution of the drive roll.

A. Set the Strike speed control to

any setting between 50 and 125

IPM. While pressing the INCH

DOWN button measure the pre-

cise length of wire fed by exactly

10 revolutions of the drive roll.

The measured length should be

within the range specified in

Table F.4 for the drive roll and

wire size employed.

B. If the measured length is not

within the specified lengths

there may be a problem with the

wire or wire feeding path. See

the

Troubleshooting Guide

(Feeding Problems)

in this sec-

tion of the manual. Also check

for correct drive roll tension

adjustment.

WIRE SPEED ACCURACY TEST (Continued)

NA-5

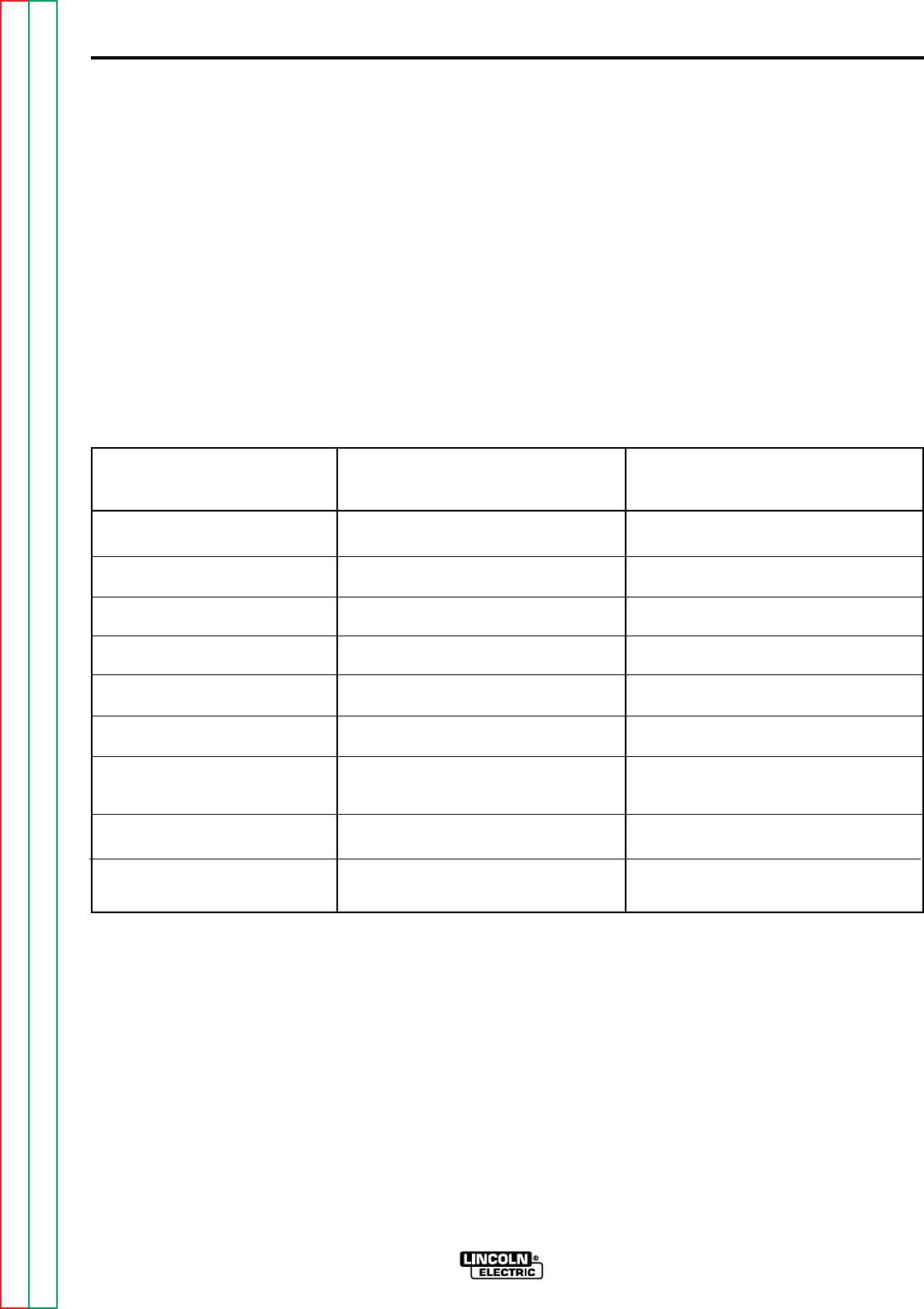

DRIVE ROLL PART WIRE SIZE RANGE INCHES OF WIRE FED PER

NUMBER 10 REVOLUTIONS OF

DRIVE ROLL

S12778 Single .035 - .052 Solid 53 - 54

S19113 Single .045 - .052 Cored 53 - 55

S12515 Single 1/16 - 3/32 51 - 53

S12514 Single 3/32 - 5/32 49 - 51

S13161-052 Twin .045 - .052 53 - 55

S13161-5/64 Twin 1/16 - 5/64 53 - 55

S14904 (Outer) Twin 3/32 51 - 52

S14905 (Inner)

S12514 Single 3/32 - 7/32 49 - 52

S14904 (Outer) Twin 5/64 - 1/8 51 - 53

S14905 (Inner)

TABLE F.4

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC