E-3

THEORY OF OPERATION

E-3

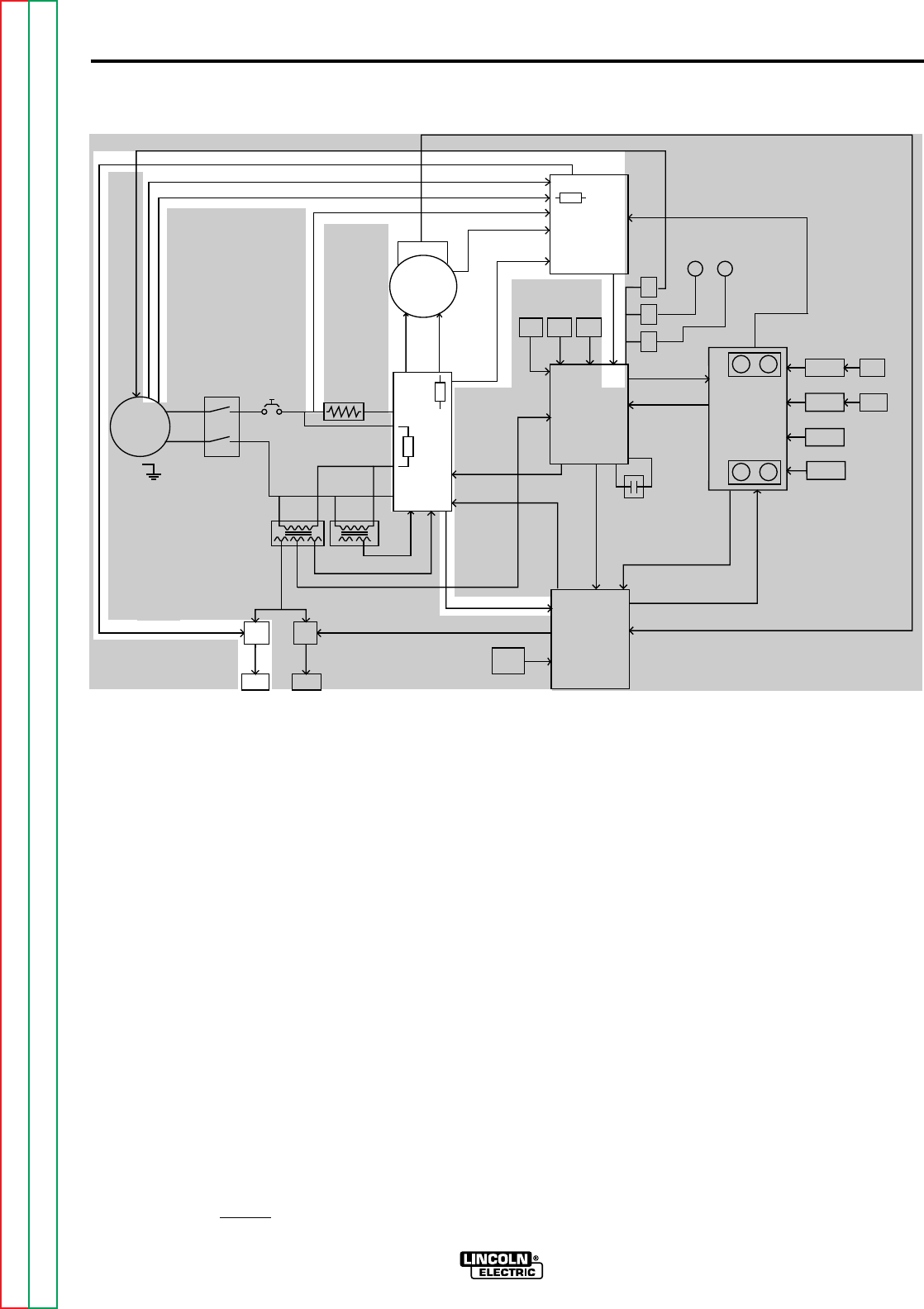

POWER AND VOLTAGE

BOARDS

The AC voltages that are received by

the power board are rectified and regu-

lated. These DC voltages are supplied

to the motor, voltage board and control

board. The two SCR-controlled

115VDC supplies power the motor

armature and field circuits.

The actual arc voltage is sensed at leads

#67(electrode) and #21(work) which are

coupled to the voltage board. The pre-

set voltage requirements are also sent to

the voltage board. This information is

compared and processed on the voltage

board and the resultant correction signal

is sent to the Lincoln CV power source

via the remote voltage leads (A,B,C).

The preset and actual arc voltage infor-

mation is also sent to the voltage meter

board where it is processed and dis-

played on the digital meter.

The voltage board also generates a low

DC voltage that is applied to the elec-

trode during the inch down mode.

When the electrode makes contact with

the work piece, this low voltage is

"loaded down", signaling the control cir-

cuitry to stop the wire feed motor. This

feature allows the operator to utilize the

"work touch sensing" feature.

If for any reason the actual welding arc

voltage does not match the set weld

voltage

(+/- 0.5Volts) the NA-5 will shutdown.

This feature insures that the actual

welding voltage is the same as the pre-

set voltage during the welding cycle.

This circuitry is incorporated on the volt-

age board.

FIGURE E.2 Power and Voltage Boards

NA-5

F1

A

R

M

A

T

U

R

E

F

I

E

L

D

V

O

L

T

A

G

E

V

O

L

T

A

G

E

T1 T2

OPTIONAL

START

BOARD

OPTIONAL

CRATER

BOARD

OPTIONAL

WELD

TIMER

BURNBACK

TIMER

VOLTAGE

BOARD

METER

BOARD

SPEED

VOLT

METER

BOARD

DIGITAL

METER

DIGITAL

METER

MOTOR

LOGIC

BOARD

CONTROL

BOARD

P

O

W

E

R

B

O

A

R

D

P

R

O

C

E

D

U

R

E

B

O

A

R

D

TACH

INCH

DOWN

SWITCH

STOP

SWITCH

START

SWITCH

WELD

CURRENT

REED SWITCH

CR

1

CR

2

CR

3

FLUX

RECEPTACLE

TRAVEL

RECEPTACLE

CONTACTOR CLOSURE (#2 AND #4)

REMOTE VOLTAGE CONTROL (A, B, C)

WORK SENSING (#21)

TACH FEEDBACK (MOTOR RPM)

DC SUPPLY VOLTAGE

10VDC REFERENCEVOLTAGE

DC VOLTAGE

S

I

G

N

A

L

INPUT

POWER

SWITCH

CIRCUIT

BREAKER

R1(2 OHMS)

MOTOR

G

A

T

E

S

I

G

N

A

L

S

CONTROL

CABLE

RECEPTACLE

TACH FEEDBACK (MOTOR RPM)

115VAC

36VAC (18+18VAC)

22VAC

1

V

A

C

0

D

C

S

U

P

P

L

Y

V

O

L

T

A

G

E

SIGNAL

A

R

C

V

O

L

T

A

G

E

S

H

U

T

D

O

W

N

A

N

D

INCH

UP

SWITCH

STRIKE/WELD PROCEDURE

ENABLE

FIELD

ARMATURE

F

E

E

D

E

N

A

B

L

E

DIRECTION

ARC VOLTS (SET & ACTUAL)

WIRE FEED SPEED (SET & ACTUAL)

E

L

E

C

T

R

ODE SENSING

(#67)

115

VAC

WELD

VOLTS SPEED

VOLTS SPEED

STRIKE

115VAC

#31

#32

1/2 AMP

F501

SET SPEED

SET VOLTAGE

START

TIMER

CRATER

TIMER

F2

NOTE: Unshaded areas of block logic diagrams are the subject of discussion.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC