F-63

TROUBLESHOOTING & REPAIR

F-63

3. Check for the proper drive roll revo-

lutions per minute. (RPM)

A. Adjust the STRIKE speed con-

trol to obtain the SET speed

specified for the speedmeter

calibration pin and head ratio

specified per Table F.5 While

pressing the INCH down button

count the drive roll revolutions in

60 seconds. The drive roll revo-

lutions and actual speed reading

should match Table F.5

B. If the readings do not match the

number in Table F.5 refer to the

Meter Circuit Accuracy Test

.

WIRE SPEED ACCURACY TEST (Continued)

NA-5

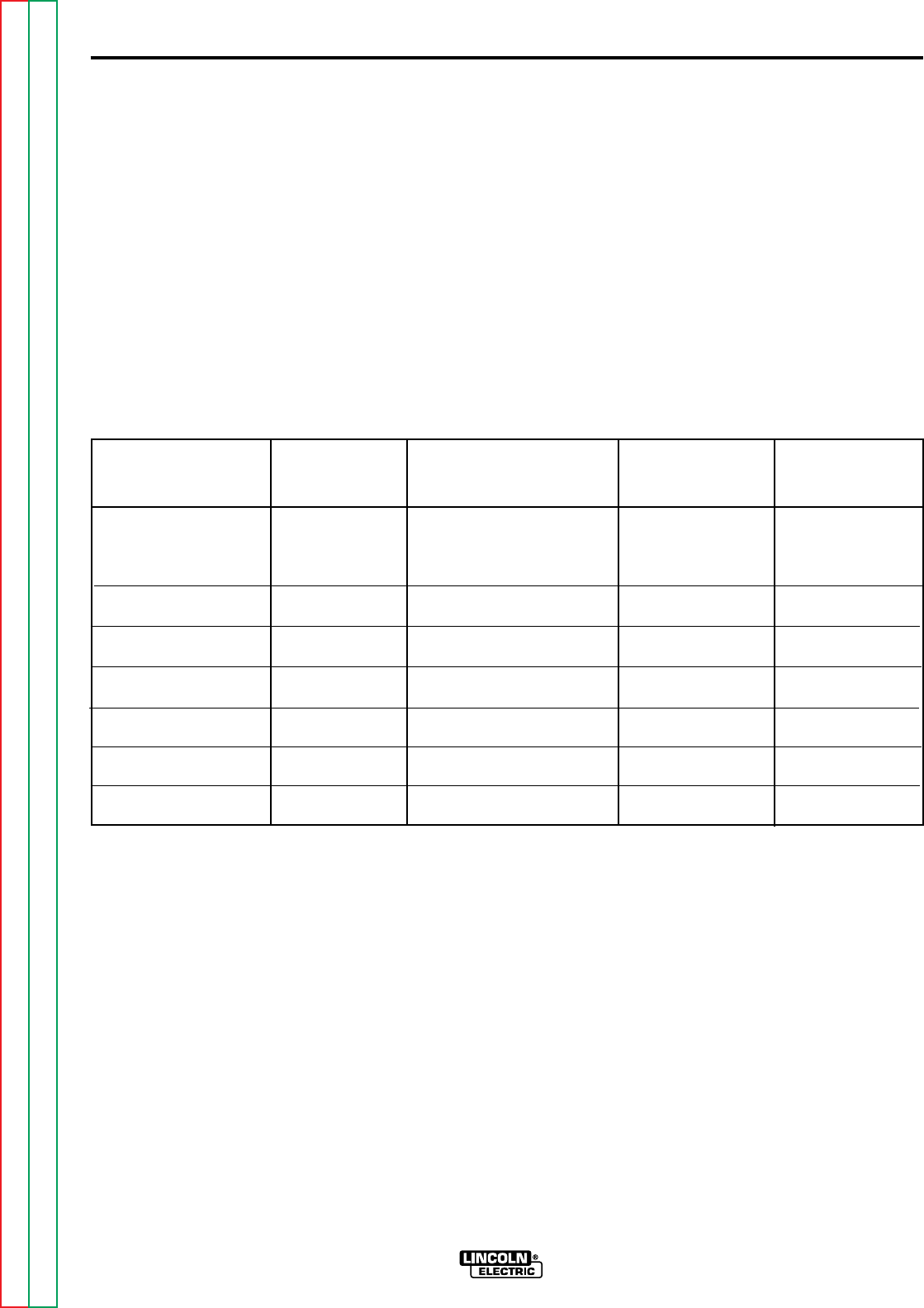

SPEEDMETER HEAD SET SPEEDMETER DRIVE ROLL ACTUAL

CALIBRATION RATIO READING (IPM) RPM SPEEDMETER

PIN READING (IPM)

21* 21/1 0.27 (IPM X 1000) 50 +/- 2 0.27 +/- 0.01

(IPM X 1000)

57F** 57/1 268 50 +/- 1 268 +/- 2

57** 57/1 262 50 +/- 1 262 +/- 2

95 95/1 249 50 +/- 1 249 +/- 2

95S*** 95/1 265 50 +/- 1 265 +/- 2

142 142/1 250 50 +/- 1 250 +/- 2

142T*** 142/1 260 50 +/- 1 260 +/- 2

TABLE F.5

* Present on HI -Speed NA-5 speedmeter board only. ** Early speedmeter pins were labeled 55F and 55,

respectively.

*** Early speedmeter PC boards did not include these calibration pins.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC