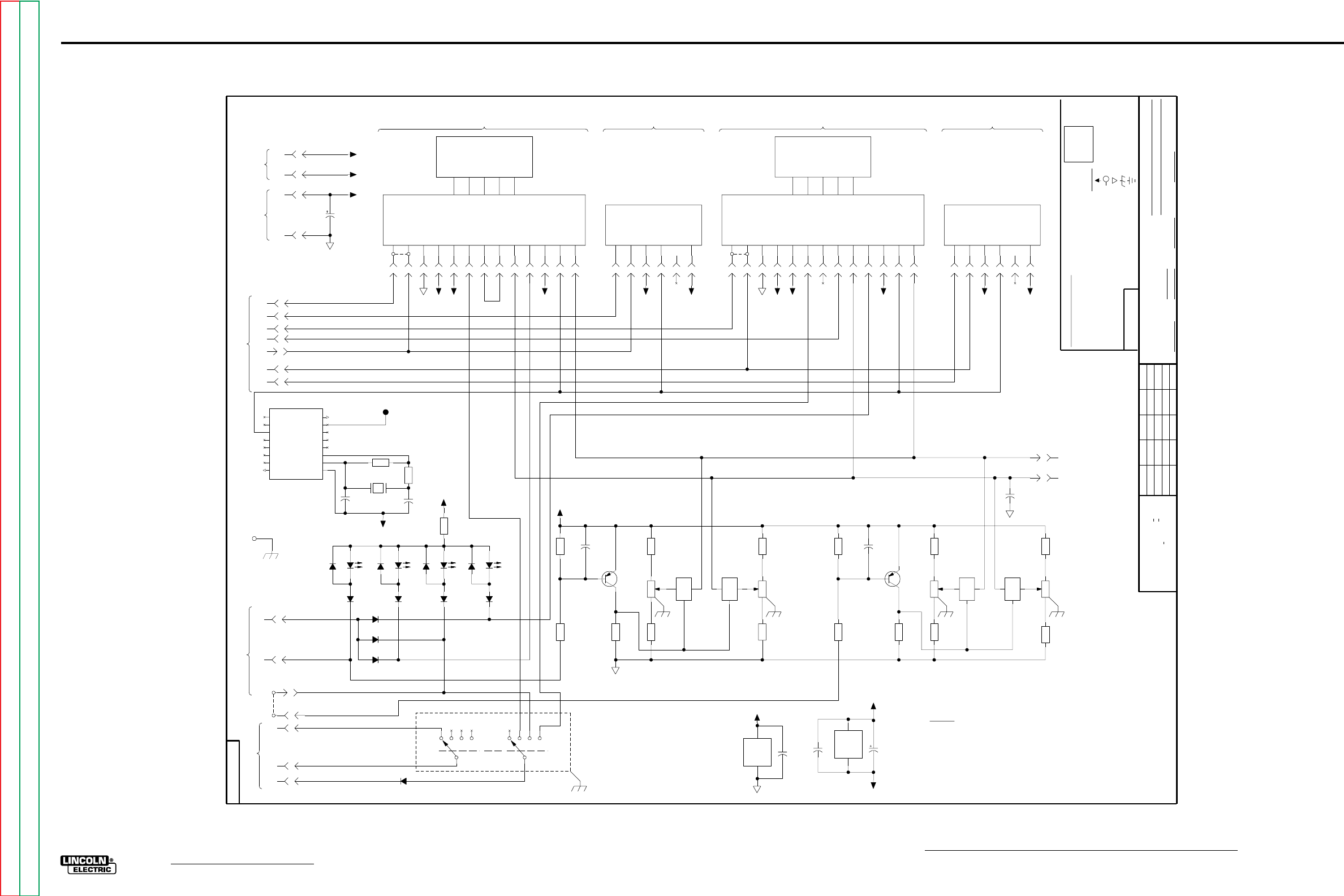

G-9

ELECTRICAL DIAGRAMS

NA-5

PROCEDURE PC BOARD SCHEMATIC

563

520

PCB

L

565

564

N.E.

SPEED

WELD

N.E.

515

500

500

515

500520

515

500

J9

4

J10

2

J10

11

J10

9

J10

6

J10

15

J10

12

J10

13

J10

14

J10

8

J9

5

J10

4

J10

1

26.7K

R16

C9

J9

6

J10

3

4.75K

R17

5.62K

R7

X1

1

2

13

10K

2W

CW

R8

C7

J19

11

X1

10

11

12

C5

J19

10

C4

332

R9

4.7

35V

C8

600mA

40V

Q2

5.62K

R4

MC14060

X2

16

8

47.5K

R18

10K

2W

CW

R5

4066B

X1

14

7

X1

4

3

5

X1

98

6

515

J8

5

J8

6

J8

1

J8

2

J8

4

J8

3

J10

7

520

VOLTS

STRIKE

N.E.

SCREW, FOR ESD.

STRIKE MODE SETTINGS

+10V

B

+5V

+10V

-10V

+5V

-10V-10V

TO PIN P8.

NUMBER.

NOTES :

NOT INSTALLED.

WELD MODE SETTINGS

+5V

A

N.E.

1.82K

R6

WELD PROCEDURE ENABLE

560

PROCEDURE KIT

LOGIC

PCB

8754

LOGIC

FRAME

581A

564A

581

584S

OUTPUT

561

RECEPTACLE

SPEED

CRATER

N.D.

-10V

500

515

+5V

655

515

I

N.C.

584

632

655 655

SELECTOR

PRESET MONITOR ENABLE

566

583S

584C

588

SUPPLIES

583C

ON LOGIC PCB

PCB

FROM REF

VOLTAGE ON

LOGIC

FROM LOGIC

CONTROL PCB

POWER

START MODULE

OPTIONAL OPTIONAL

WELD TIMER MODULE

D12

J18

6

J19

13

J18

5

8

16

Q7

Q14

Q13

MC14060

Q9

OUT2

Vdd

Vss

RES

Q10

Q8

Q6

Q12

Q5

CLKQ4

OUT1

X2

13

14

15

10

11

12

9

7

6

5

4

3

1

2

J18

1

N.A. SINCE COMPONENTS OR CIRCUITRY ON A PRINTED CIRCUIT BOARD MAY CHANGE

N.C. A JUMPER PLUG CONNECTS 584C TO 583C WHEN THE OPTIONAL START MODULE IS

510P

562

O

500

583

515

588A

655

520

OPTION BOARD

TIMER BOARD

POWER SUPPLY DISTRIBUTION

NOT INSTALLED. ALSO, LOGIC CIRCUIT 694 LEAD MUST BE MOVED FROM PIN P10

CD

NOT SHOW THE EXACT COMPONENTS OR CIRCUITRY OF CONTROLS HAVING A COMMON CODE

N.B. A JUMPER PLUG CONNECTS 584S TO 583S WHEN THE OPTIONAL START MODULE IS

WITHOUT AFFECTING THE INTERCHANGEABILITY OF A COMPLETE BOARD, THIS DIAGRAM MAY

500

TIMER BOARD

515

655

O

I

515

562

500

655

I

CRATER MODULE

632635

588

N.D. 564 IS CONNECTED TO 564A BY A LEAD RECEPTACLE JUMPER PLUG, WHICH IS

N.E. R2, R5, R8, R11 AND S1 ARE CONNECTED TO FRAME BY PCB TRACES AND MOUNTING

REMOVED WHEN THE OPTIONAL MULTI-PROCEDURE KIT IS INSTALLED.

AND BYPASSING

OPTIONAL

-10V

BURNBACK TIMER

D2

D3

STRIKE

+10V

LED3

D4

1/2W

10M

R20

D7

D11

100V

47p

C3

C1

S1

3

42 5

C2

S1

9

10

8

11

J18

3

635

562

OPTION BOARD

+5V

DIGITAL TIMERS

N.E.

-10V

STRIKE PROCEDURE

DISABLE

START

WELD

+5V

STRIKE

WELD

PRESET MODE

START

STRIKE

B

CRATER

STRIKE

A

STRIKE PROCEDURE

ENABLE

START DISABLE

WELD PROCEDURE ENABLE

START DISABLE

1.6384MHz

Y1

LED2

J19

14

J18

4

J19

4

D1

100V

22p

C2

LED1

D5

10K

2W

CW

R2

600mA

40V

Q1

5.62K

R1

C6

47.5K

R14

26.7K

R15

267

R3

4.75K

R13

D10

LED4

D6

D8

2.21K

R19

D9

N.E.

VOLTS

TO SET

ON 2 PLACE DECIMALS IS + .O2

ON CONTROL PCB

SPEED BUFFER

TO SET

VOLTAGE BUFFER

632

635

ON HOLES SIZES PER E-2056

ON VOLTAGE PCB

WELD

Ch'ge.Sht.No.

10-29-91

21

SCHEMATIC

EARTH GROUND CONNECTION

LAST NO. USED

POWER SUPPLY SOURCE POINT

COMMON CONNECTION

SHT.

NO.

L

8754

VOLTAGE NET

NA-5 PROCEDURE

FRAME CONNECTION

12

9

FILE: L8754_3DB

SCALE

MFD

1A, 400V

DIODES =

RESISTORS = Ohms (

NONE

(

THE LINCOLN ELECTRIC CO.

CLEVELAND, OHIO U.S.A.

GENERAL INFORMATION

ELECTRICAL SYMBOLS PER E1537

CAPACITORS =

CHK.

(UNLESS OTHERWISE SPECIFIED)

UNLESS OTHERWISE SPECIFIED)

UNLESS OTHERWISE SPECIFIED)

.022/50V

1/4W

C-

EQUIP.

SUBJECT

TYPE

SUP'S'D'G.

UNLESS OTHERWISE SPECIFIED TOLERANCE

MATERIAL TOLERANCE ("t") TO AGREE

ON 3 PLACE DECIMALS IS + .OO2

ON ALL ANGLES IS + .5 OF A DEGREE

DR.

DATE

FM

WITH PUBLISHED STANDARDS

SUPPLY

LABELS

D-

R-

1.82K

R12

5.62K

R10

10K

2W

CW

R11

515

J11

6

J19

8

J19

6

J19

9

J18

2

J19

1

J19

7

J11

4

J19

2

J19

15

J19

3

J9

1

J9

3

O

J11

14

J9

2

J11

15

18

15V

C1

J11

11

J11

13

J11

8

J11

12

J11

9

J11

2

J11

1

J11

7

J11

3

J19

5

500

520

500

515

500

515

520

TIMER BOARD

515

510P

520

500

515

BURNBACK TIME OVER

START TIME OVER/WELD TIME INITIATE

CRATER TIME INITIATE

CRATER TIME OVER/BURNBACK TIME INITIATE

CURRENT

WELD TIME OVER

START TIME INITIATE

+10V

584

N.B.

I

500

O

1.6384 MHz

TEST POINT

FOR

TIME BASE

100 Hz

TIME BASE

+5V

510P

588588A

562

583

520

TIMER BOARD

+10V

500

-10V

7.68K

R21

3-6-92B

7-10-92N

7-12-96N

G-9

NOTE: Lincoln Electric assumes no responsibility for liablilities resulting from board level troubleshooting. PC Board repairs will invalidate your factory warranty. Individual Printed Circuit Board Components are not avail-

able from Lincoln Electric. This information is provided for reference only. Lincoln Electric discourages board level troubleshooting and repair since it may compromise the quality of the design and may result in

danger to the Machine Operator or Technician. Improper PC board repairs could result in damage to the machine.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC