Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-9 F-9

IDEALARC R3R

Observe Safety Guidelines TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

216-383-2531 or 1-800-833-9353.

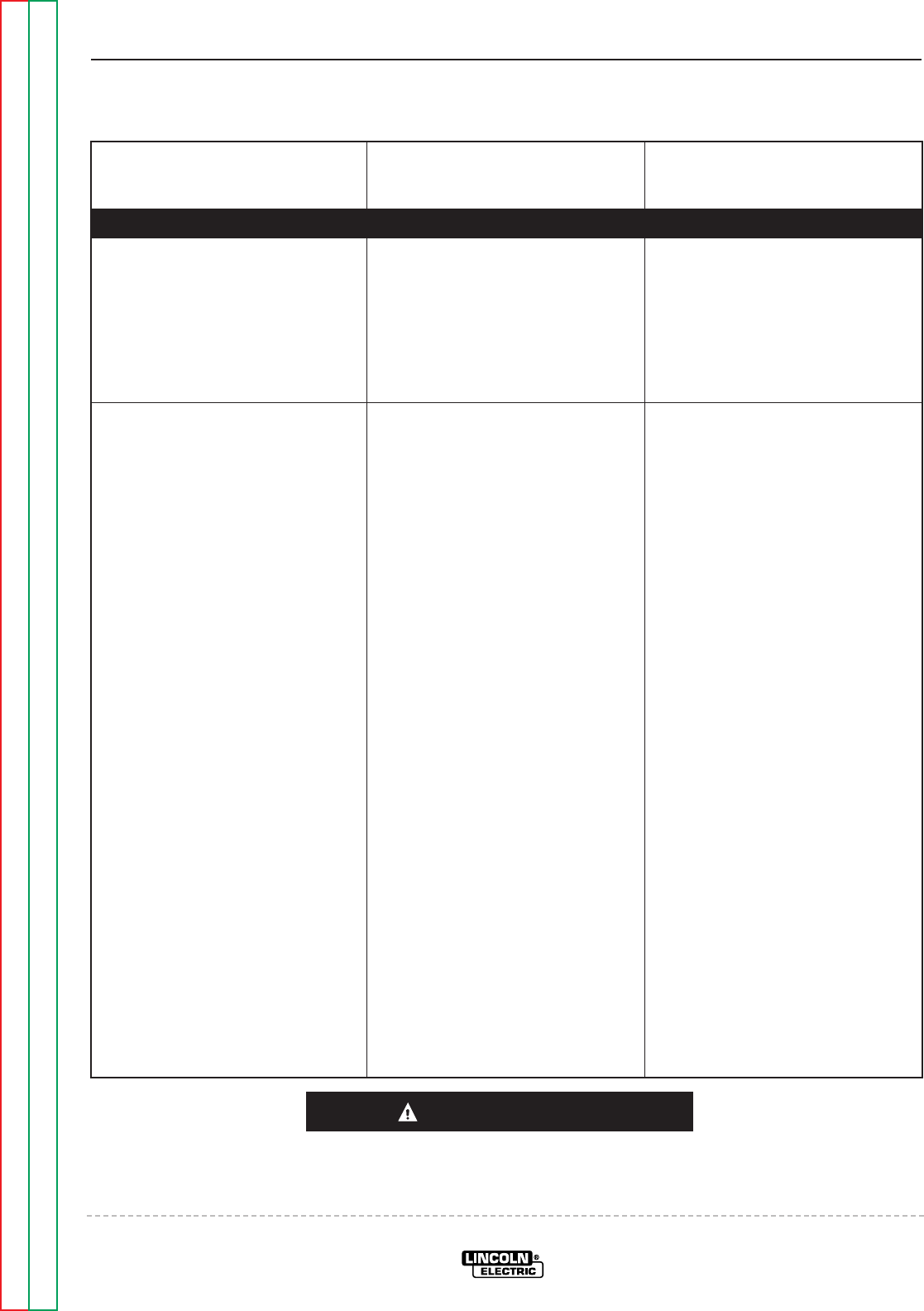

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

WELDING PROBLEMS

Poor arc characteristics. 1. Make sure the correct weld pro-

cedures are being used.

(Electrode, Polarity, etc.)

2. Check the welding cables for

loose or faulty connections.

1. Perform the SCR/Diode

Rectifier Bridge Test.

2. Perform the Main Transformer

Test.

3. The control board may be

faulty. Replace.

The welding arc is variable and

sluggish.

1. Check the input voltage at the

R3R, making sure the correct

voltage and all three phases are

being applied to the machine.

2.

Make sure the welding

process is correct for the

machine settings.

3. Check the welding cables for

loose or faulty connections.

Also make sure the cables are

sized correctly for the welding

current.

1. Perform the SCR/Diode

Rectifier Bridge Test.

2. Perform the Main Trans-

former Test.

3. The control board may be

faulty. Replace.