Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-33 F-33

IDEALARC R3R

POCKET AMPTROL CIRCUIT TEST (continued)

8. Connect the Pocket Amptrol unit from the

work to the electrode welding output termi-

nals. Jumper wires may be necessary.

Electric Shock can kill.

• With the input power

on, there are high volt-

ages inside the

machine. Do not reach

into the machine or

touch any internal part

of the machine while the

power is on.

9. Turn on the R3 machine.

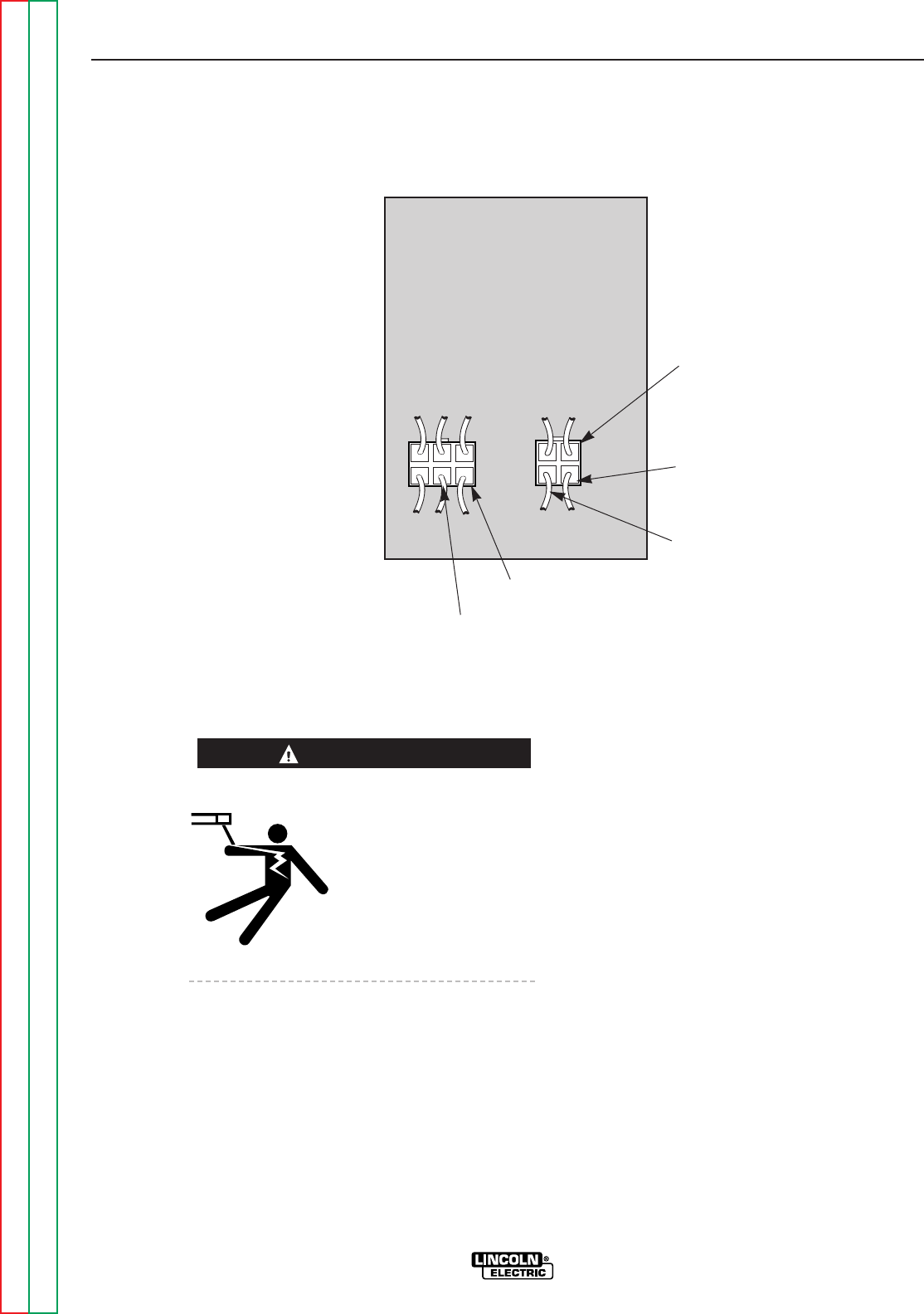

10. Check for the following voltages at plug P6

pin 1(+) (lead #218) to pin 2(–) (lead #219).

Plug 6 is located on the Pocket Amptrol

board. See Figure F.22.

a. With the Pocket Amptrol in position “1”,

the voltage should be approximately

40.8mV.

b. With the Pocket Amptrol in position “10”,

the voltage should be approximately

138.9mV.

If the correct AC voltages are applied to the

PC board and the correct DC mV is sensed

at plug P6 pins 1 and 2, the Pocket Amptrol

circuit should function properly. If it does

NOT, check the leads between the plug P6

(leads #75, #76 and #77) (see Figure F.24)

and the local remote switch (SW2). See the

Wiring Diagram. If the leads are OK, the PC

board may be faulty.

If the correct AC voltages are applied to

the PC board and the DC mV are not cor-

rect, check the sensing resistor (R4). See

Figure F.23 and the Wiring Diagram. Normal

resistance is 0.4 ohms.

If the resistance at R4 is normal (0.4 ohms)

the Pocket Amptrol board may be faulty.

FIGURE F.22 – POCKET AMPTROL BOARD PLUG P6 AND P7 LOCATION

P6

Pin 3 (Green)

Pin 1 (Green)

Pin 2 (Yellow)

Pin 1 (Lead #218)

Pin 2 (Lead #219)

P7

WARNING