#$&(#"

&&#"(&# $"

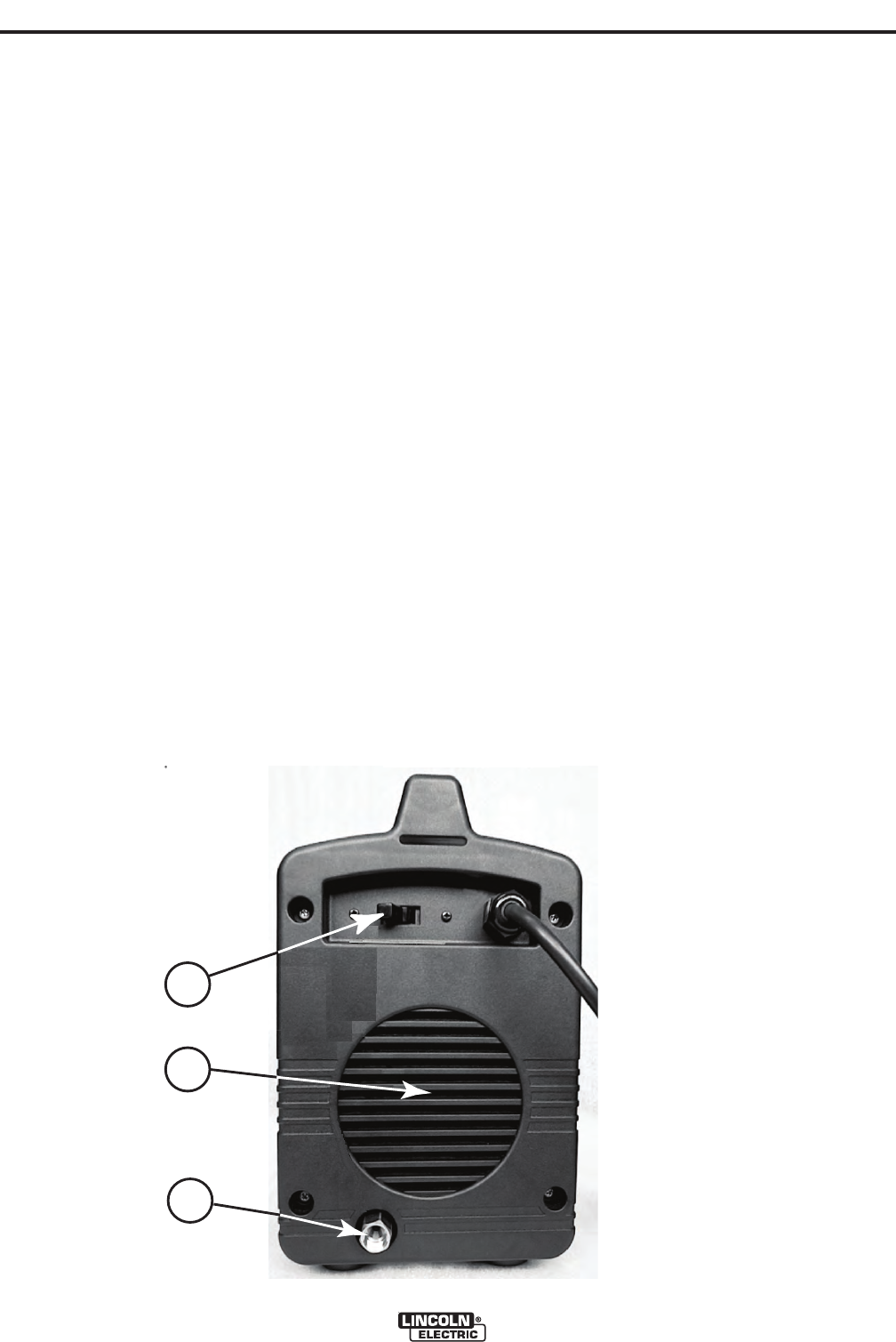

$>F4A'F8C27 Controls the input power to the

machine. Make sure the machine is properly con-

nected to the input supply before turning the

machine on.(See Figure B.1)

0= The cooling fan will turn ON when the

machine is turned ON and it will continue to run

whenever the output of the machine is ON. If the

output of the machine is OFF for more than five min-

utes, the fan will turn OFF. This reduces the amount

of dirt that is deposited inside the machine and

reduces power consumption.(See Figure B.1)

Refer to the Output LED section below for more

information about conditions when the output of the

machine is ON.

0B=;4C Connector for the TIG shielding gas. The

gas source must have a pressure regulator and

flow gage installed.(See Figure B.1)

#"(&# '"'(("'(See Figure B.2)

!>34'F8C27 This switch changes the welding

modes of the machine. The V160-T has three weld-

ing modes: 'C82: (SMAW), 85C( (GTAW) and

( (GTAW).

When the mode switch is in the Stick position, the fol-

lowing welding features are enabled:

• Hot Start: This is a temporary increase in the output

current during the start of the stick welding process.

This helps ignite the arc quickly and reliably.

• Arc Force: This is a temporary increase in the out-

put current during normal stick welding. This tem-

porary increase in output current is used to clear

intermittent connections between the electrode and

the weld puddle that occur during normal stick

welding.

• Anti-Sticking: This is a function which decreases

the output current of the machine to a low level

when the operator makes an error and sticks the

electrode to the work piece. This decrease in cur-

rent allows the operator to remove the electrode

from the electrode holder without creating large

sparks which can damage the electrode holder.

*(

1

2

3

1

2

3

)&

$>F4A'F8C27

0=

0B=;4C