- Always wear snug fitting clothes and take off rings, bracelets and watches before operating this machine.

- While this machine is in operation the cutterblock must be completely covered, by fence, cutterblock guard,

and workpiece.

- Wear hearing protection for all jointing and planing operations (warning symbol shown above). The sound

pressure level can rech up to 87 dB(A).

- Check stock before working it for cracks, intergrown knots, warps and inclusion of foreign material.

- Do not exceed maximum permissible torque when tightening lock bar screws (see para. 15).

- When operated with wheel set installed support machine with all four levelling screws to keep it from tipping.

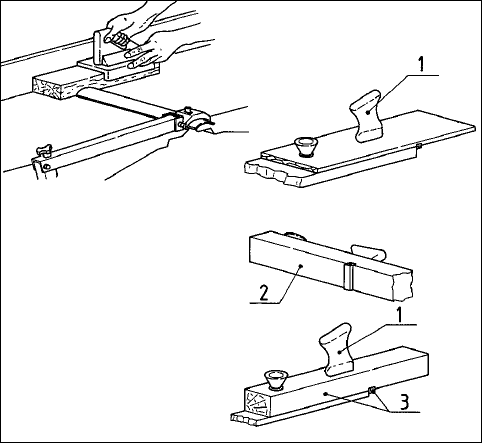

11 Push Blocks and Feeding Fixtures

1) Handles dowelled and glued to prevent metal

making contact with the planer blades.

2) Underside of push block faced with sandpaper

or soft rubber, for better contact and guiding of

the workpiece.

3) Use narrow, two-handed push block for short,

narrow and thin stock. Glue a piece af hardwood

across the push block serving as stop.

9. Workpiece Dimensions

9.1 HC 410

Planing/Jointing

The max. permissible workpiece size is 1700 x 410 mm when using the standard machine tables. If workpieces

of greater length are to be worked additional support is required, e.g. by using roller stands. The smallest size

for manual feeding by hand must not be less than 300 X 40 X 20 mm. Smaller workpieces must be fed with

a suitable push block.

Thicknessing

The maximum workpiece size is 1700 x 405 x 230 mm. For longer work additional support (roller stands) is

required. Minimum size is 250 x 15 x 5 mm.

9.2 Stock Pre-Checking

Every workpiece must be checked for possible flaws, to see if it is suitable for planing/thicknessing (warping,

knots, cracks, inclusions of foreign material), before it is worked.

Caution! Do not work stock with loose knots or knots which may fall out easily.

- The knots coming off may be thrown about, with a risk of personal injury and damage to the machine.

10 Dangerous Operations

- With this planer/thicknesser no set-in work must be carried out. Set-in work is a planing operation where the

planing starts or stops short of one end of the workpiece.

- Do not attempt to plane heavily warped stock, which does not rest with its full length on the planing tables.