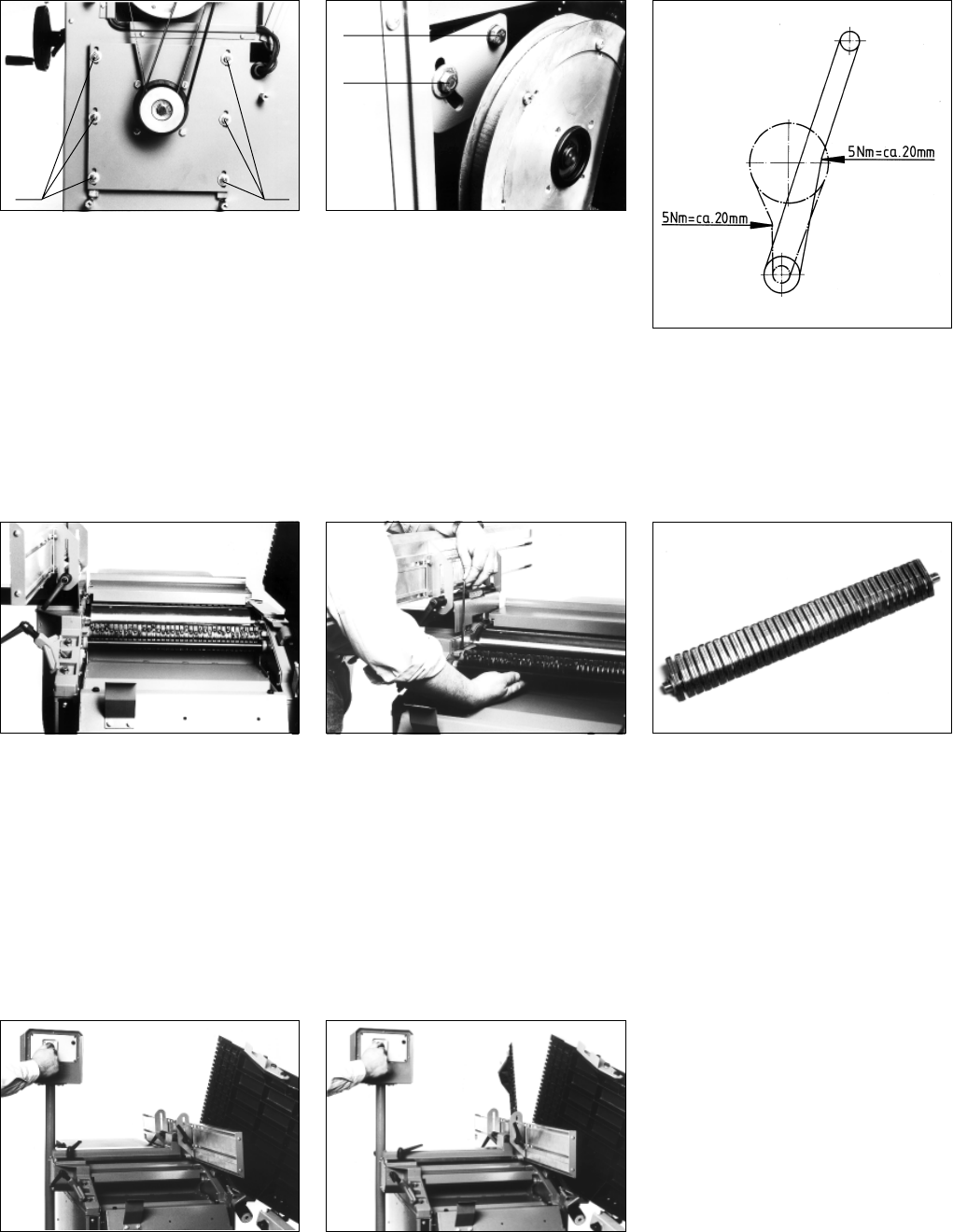

16.2 Drive Belt Tension/Replacement

After loosening the six nuts (A) the

motor mounting plate can be pushed

downward to tension the main drive

belt.

Loosen screws (B and C) to move the

transmission base plate for tensioning

the thicknesser drive belt.

Play of main drive belt at 5 Nm tension

approx. 20 mm

Play of thicknesser drive belt at 5 Nm

approx. 20 mm.

B

C

AA

16.4 Checking Limit Switches and Motorbrake

Note: In case of a damaged limit switch lead the machine may start during testing. This test should therefore only be

carried out by qualified service personel.

Swing the infeed table up to its upright

position and cover the cutterblock by

setting the fence assembly against

the table.

When actuating the switch the ma-

chine must not start.

Swing the outfeed table up to its upright

position and cover the cutterblock by

setting the fence assembly against

the table.

The braking period (time to motor

standstill) must be checked in at least

monthly intervals. The braking period

must not be more then 10 sec. If the

motor needs more then 10 sec. to

come to standstill, the motorbrake or

the complete motor have to be

replaced.

16.3 Servicing/Replacing the Recoil Lock

Damaged or worn anti-kickback

fingers must be replaced by genuine

metabo anti-kickback fingers (see spa-

re parts list for ordering information).

After removal of the two fastening

screws the recoil lock assembly is

removed from the machine.

New anti-kickback fingers must slide

easily and move freely on the recoil

lock shaft. After the recoil lock

assembly is reinstalled check for its

proper function.