12 Controls

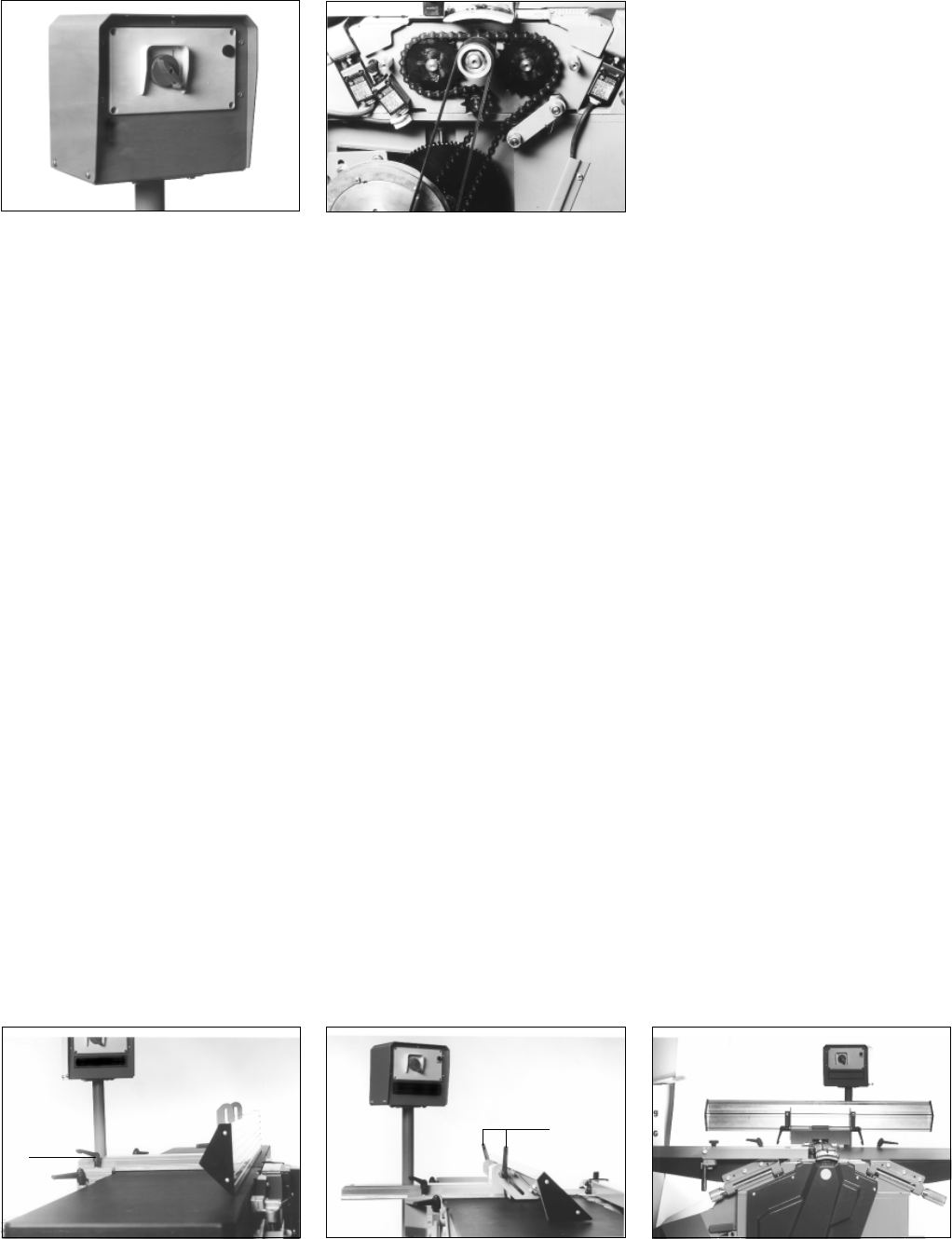

12.1 Switch Terminal/Electrical Equipment

The raised switch panel can be turned

to point towards the operator position

for easy access. Turn rotary switch

clockwise to start machine, turn coun-

ter-clockwise to switch the machine

off. To prevent unauthorized use the

switch can be blocked with a padlock.

12.2 Switch/Overload Protection

The switch is equipped with a no-volt release solenoid (magnetic switch), to prevent start-up after a power failure. If the

machine is not connected to the power mains the switch does not engage. In the event of a power failure the machine

has to be restarted. In case of an overload of the motor the build-in motor protection relay trips and cuts the power to

the motor. If the motor is shut off repeatedly by the overload relay, check machine (motor brake action, blade sharpness,

low voltage etc.) A cooling down period of 10 min. is recommended before switching ON again.

12.3 Motor Brake

The motor supplied with this machine is equipped with an electro-mechanical motor brake, designed for a long service

life. Friction, however, causes the brake pad to wear. If the braking action fades (time to cutterblock standstill exceeds

10 sec.) the motorbrake has to be replaced. The max. permissible number of 10 switching actuation per hour should

not be exceeded.

12.4 Canting Fence Adjustment

Loosening the ratchet lever (A) al-

lows for lateral adjustment of the fence

carrier.

After loosening both ratchet levers (B)

the fence can be set from the 90°

position to the 45° position.

When changing from planing to thick-

nessing mode the fence is swung up.

B

A

Three limit switches, located behind

the thicknesser drive gear cover, pre-

vent the starting of the machine if it is

not properly set for the planing or

thicknessing mode. The limit switches

will also switch the machine off if

- the planing beds are swung up

- the chip ejection hood is swung

from the cutterblock when thick-

nessing