6-5.

Clean

Air

Intake

And

Cooling

Areas

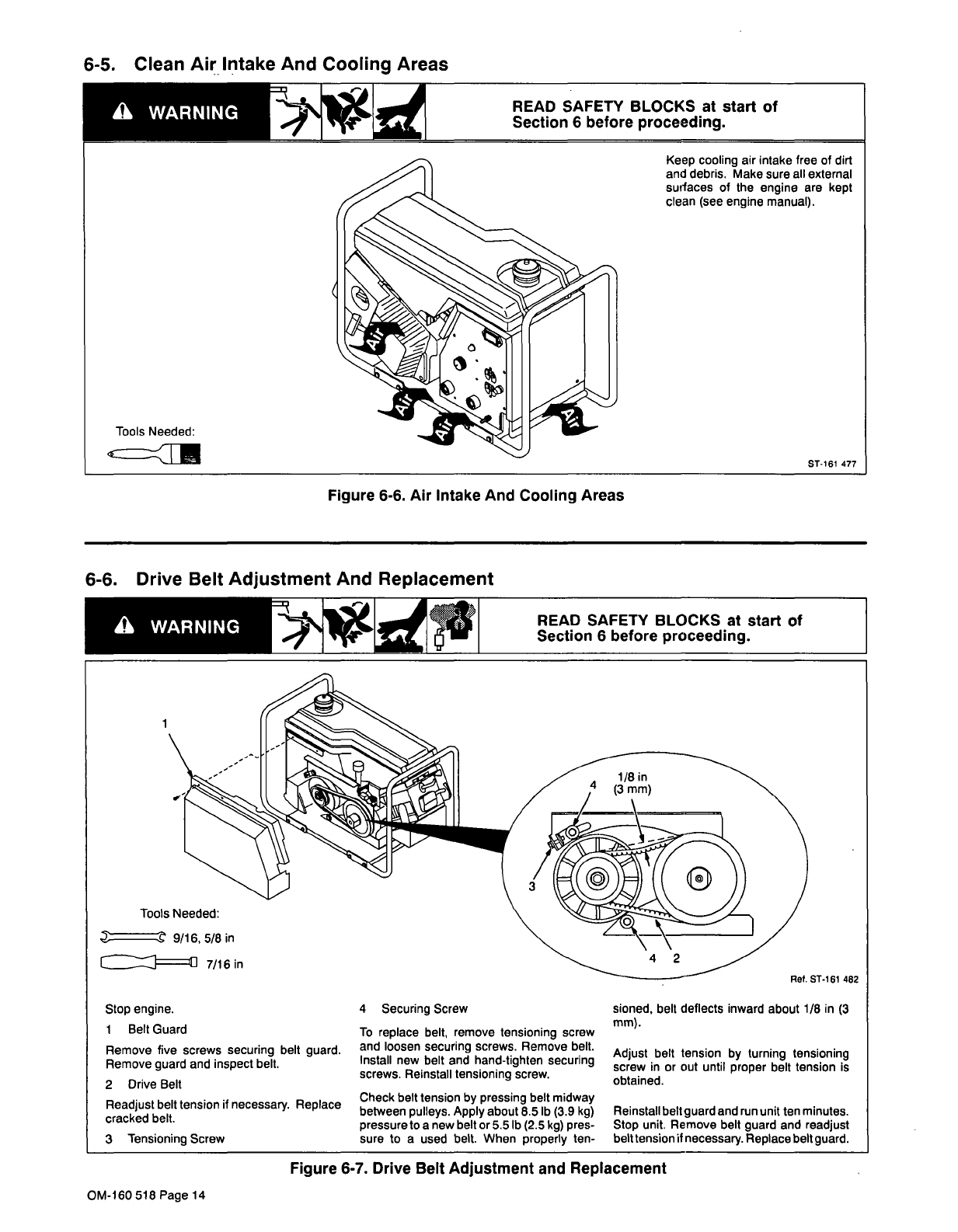

6-6.

Drive

Belt

Adjustment

And

Replacement

I

~

READ

SAFETY

BLOCKS

at

start

of

Section

6

before

proceeding.

Figure

6-7.

Drive

Belt

Adjustment

and

Replacement

Figure

6-6.

Air

Intake

And

Cooling

Areas

Tools

Needed:

~

9/16,5/8

in

7/16

in

Ref.

ST-161

482

Stop

engine.

4

Securing

Screw

sioned,

belt

deflects

inward

about

1/8

in

(3

mm).

1

Belt

Guard

To

replace

belt,

remove

tensioning

screw

Remove

five

screws

securing

belt

guard.

and

loosen

securing

screws.

Remove

belt.

Adjust

belt

tension

by

turning

tensioning

Remove

guard

and

inspect

belt.

Install

new

belt

and

hand-tighten

securing

screw

in

or

out

until

proper

belt

tension

is

screws.

Reinstall

tensioning

screw,

obtained.

2

Drive

Belt

Check

belt

tension

by

pressing

belt

midway

Readjust

belt

tension

if

necessary.

Replace

between

pulleys.

Apply

about

8.5

lb

(3.9

kg)

Reinstall

belt

guard

and

run

unit

ten

minutes.

cracked

belt.

pressure

to

a

new

belt

or

5.5

lb

(2.5

kg)

pres-

Stop

unit.

Remove

belt

guard

and

readjust

3

Tensioning

Screw

sure

to

a

used

belt.

When

properly

ten-

belttensionifnecessary.Replacebeltguard.

OM-160

518

Page

14