1

Electrode

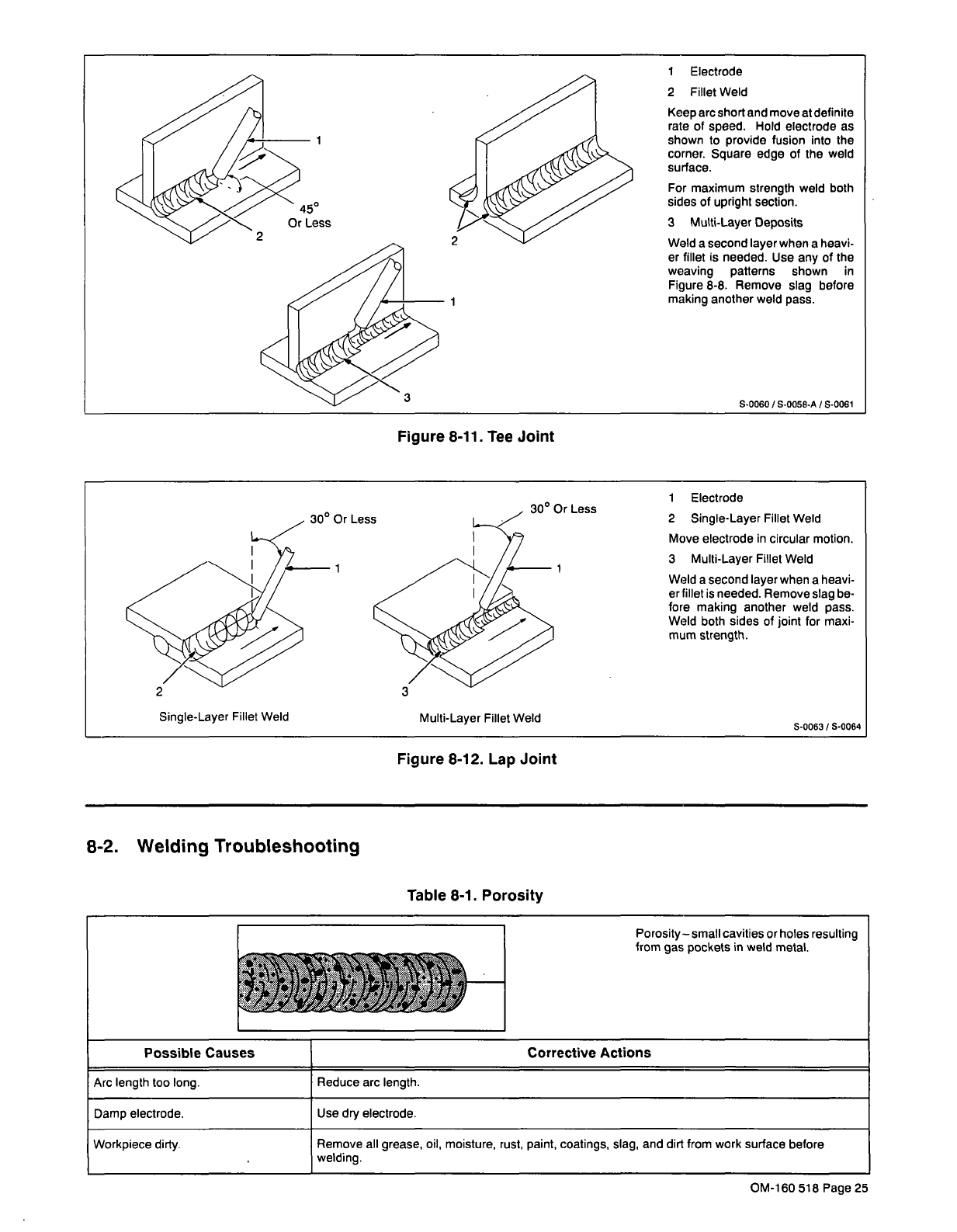

Figure

8-11.

Tee

Joint

Figure

8-12.

Lap

Joint

8-2.

Welding

Troubleshooting

Table

8-1.

Porosity

~

Porosity

small

cavities

or

holes

resulting

from

gas

pockets

in

weld

metal.

Possible

Causes

Corrective

Actions

Arc

length

too

long.

Reduce

arc

length.

Damp

electrode.

Use

dry

electrode.

Workpiece

dirty.

.

Remove

all

grease,

oil,

moisture,

rust,

paint,

coatings,

slag,

and

dirt

from

work

surface

before

welding.

2

Fillet

Weld

Keep

arc

short

and

move

at

definite

rate

of

speed.

Hold

electrode

as

shown

to

provide

fusion

into

the

corner.

Square

edge

of

the

weld

surface.

For

maximum

strength

weld

both

sides

of

upright

section.

3

Multi-Layer

Deposits

Weld

a

second

layer

when

a

heavi

er

fillet

is

needed.

Use

any

of

the

weaving

patterns

shown

in

Figure

8-8.

Remove

slag

before

making

another

weld

pass.

S-0060

/

S-0058-A

/

S-OO61

2

1

Electrode

300

Or

Less

2

Single-Layer

Fillet

Weld

Move

electrode

in

circular

motion.

3

Multi-Layer

Fillet

Weld

1

Weld

a

second

layer

when

a

heavi

er

fillet

is

needed.

Remove

slag

be

fore

making

another

weld

pass.

Weld

both sides

of

joint

for

maxi

mum

strength.

Single-Layer

Fillet

Weld

Multi-Layer

Fillet

Weld

S~oo63

/S-0064

3

OM-160

518

Page

25