6-8.

Troubleshooting

AA

WARNING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Always

wear

dry

insulating

gloves.

Insulate

yourself

from

work

and

ground.

Stop

engine

before

installing

or

servicing.

Keep

all

panels

and

covers

securely

in

place

ENGINE

EXHAUST

GASES

can

kill.

Do

not

breathe

exhaust

fumes.

Use

in

open,

well-ventilated

areas,

or

vent

exhaust

outside

and

away

from

any

building

air

intakes.

HOT

PARTS

can

cause

severe

burns.

Allow

cooling

period

before

servicing.

Wear

protective

gloves

and

clothing

when

working

on

a

hot

engine.

ENGINE

FUEL

can

cause

fire

or

explo

sion.

Stop

engine

before

fueling.

Do

not

fuel

while

smoking

or

near

sparks

or

flames.

Do

not

overfill

tank;

clean

up

any

spilled

fuel.

MOVING

PARTS

can

cause

injury.

Keep

away

from

moving

parts

such

as

fans,

belts,

and

rotors.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

Troubleshooting

to

be

performed

only

by

qualified

persons.

rwarnhl.1

11/91

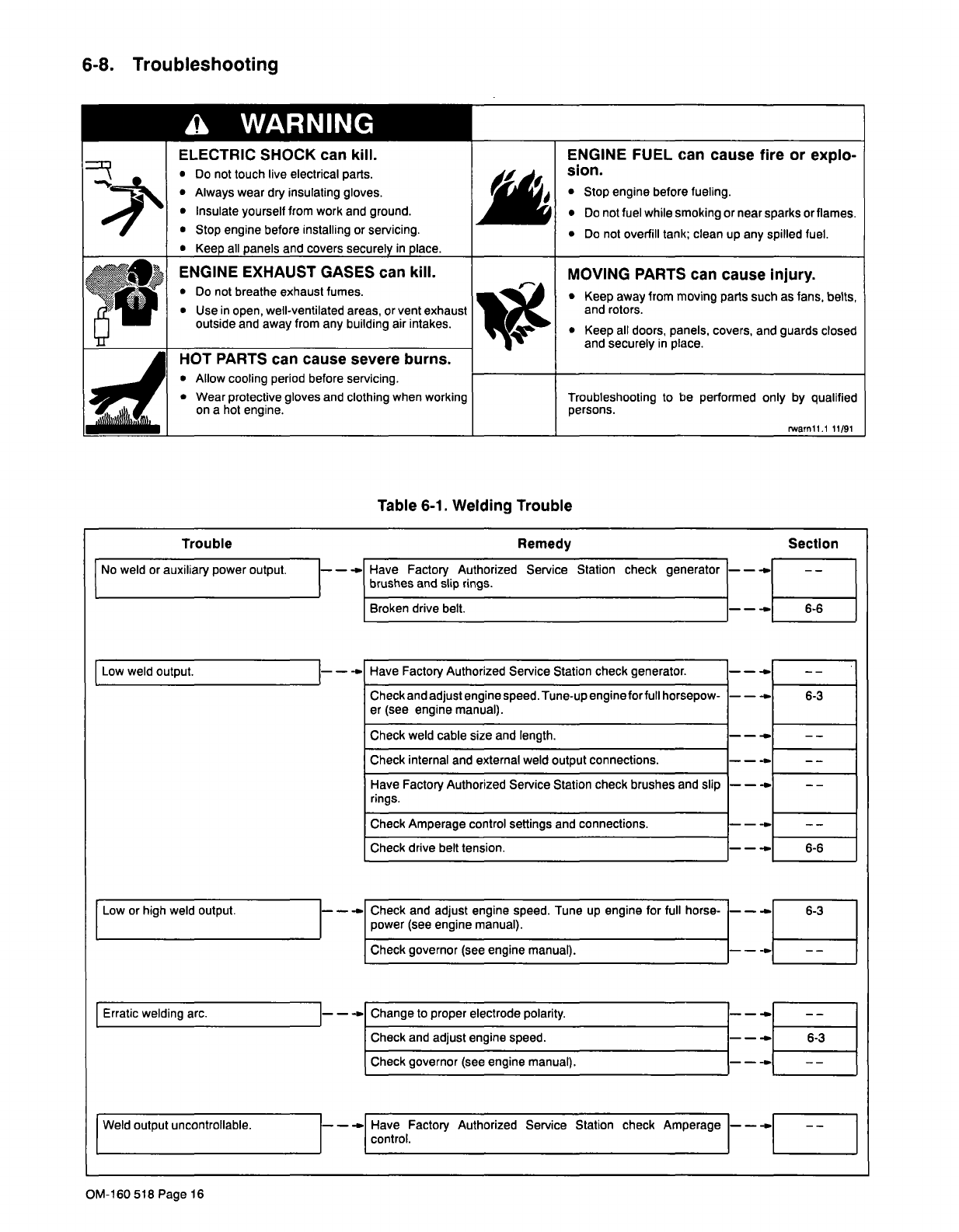

Table

6-1.

Welding

Trouble

Trouble

No

weld

or

auxiliary

power

output.

-~

Remedy

Low

weld

output.

Broken

drive

belt.

Have

Factory

Authorized

Service

Station

check

generator

brushes

and

slip

rings.

-~

Section

---~

--

-..

6-6

Have

Factory

Authorized

Service

Station

check

generator.

-~

-~

6.3

Check

and

adjust

engine

speed.

Tune-up

engine

forfull

horsepow

er

(see

engine

manual).

Check

weld

cable

size

and

length.

Check

internal

and

external

weld

output

connections.

Have

Factory

Authorized

Service

Station

check

brushes

and

slip

rings.

Check

Amperage

control

settings

and

connections.

--

-~

Check

drive

belt

tension.

Low

or

high

weld

output.

-a

--

-~

6-6

Erratic

welding

arc.

Check

and

adjust

engine

speed.

Tune

up

engine

for

full

horse

power

(see

engine

manual).

Check

governor

(see

engine

manual).

Change

to

proper

electrode

polarity.

-~

6-3

-a

--

Check

and

adjust

engine

speed.

Weld

output

uncontrollable.

Check

governor

(see

engine

manual).

-a

--

-~

6-3

---

--

-~

Have

Factory

Authorized

Service

Station

check

Amperage

-~

control.

OM-160

518

Page

16