SECTION

8-

WELDING

METHODS

&

TROUBLESHOOTING

mcd5.~

9192

a

WARNING

ELECTRIC

SHOCK

can

kill.

Always

wear

dry

insulating

gloves.

Insulate

yourself

from

work

and

ground.

Do

not

touch

live

electrical

parts.

Keep

all

panels

and

covers

securely

in

FUMES

AND

GASES

can

be

hazardous

to

your

health.

Keep

your

head

out

of

the

fumes.

Ventilate

area,

or

use

breathing

device.

Read

Material

Safety

Data

Sheets

(MSDSs)

and

manufacturers

instructions

for

material

used.

WELDING

can

cause

fire

or

explosion.

Do

not

weld

near

flammable

material.

Watch

for

fire;

keep

extinguisher

nearby.

Do

not

locate

unit

over

combustible

surfaces.

Do

not

weld

on

closed

containers.

Allow

work

and

equipment

to

cool

before

handling

ARC

RAYS

can

burn

eyes

and

skin;

NOISE

can

damage

hearing.

Wear

welding

helmet

with

correct

shade

of

filter.

Wear

correct

eye,

ear,

and

body

protection.

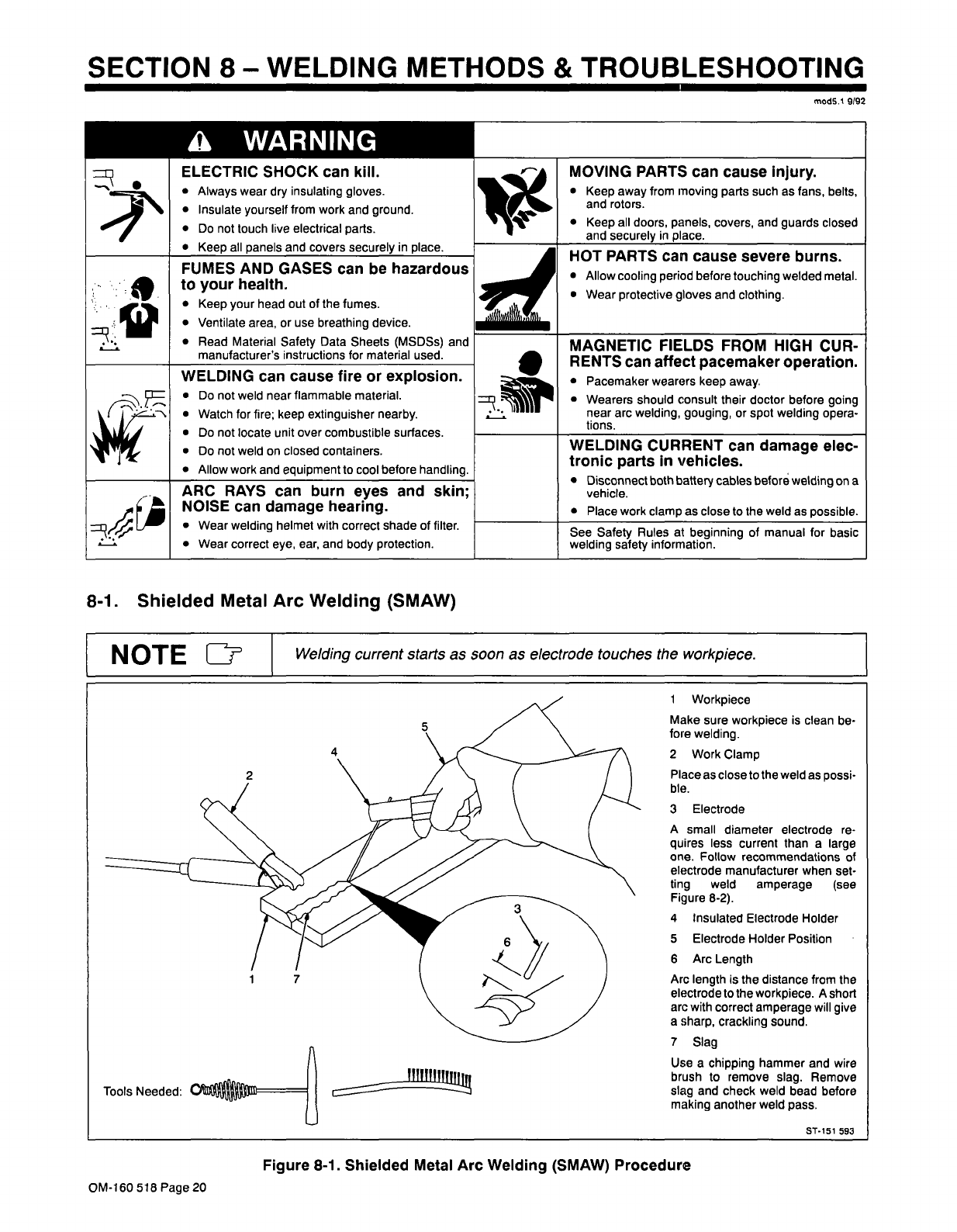

8-1.

Shielded

Metal

Arc

Welding

(SMAW)

MOVING

PARTS

can

cause

injury.

Keep

away

from

moving

parts

such

as

fans,

belts,

and

rotors.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

HOT

PARTS

can

cause

severe

burns.

Allow

cooling

period

before

touching

welded

metal.

Wear

protective

gloves

and

clothing.

MAGNETIC

FIELDS

FROM

HIGH

CUR

RENTS

can

affect

pacemaker

operation.

Pacemaker

wearers

keep

away.

Wearers

should

consult

their

doctor

before

going

near

arc

welding,

gouging,

or

spot

welding

opera

tions.

WELDING

CURRENT

can

damage

elec

tronic

parts

in

vehicles.

Disconnect

both

battery

cables

before

welding

on

a

vehicle.

Place

work

clamp

as

close

to

the

weld

as

possible.

See

Safety

Rules

at

beginning

of

manual

for

basic

welding

safety

information.

N

OTE

~

Welding

current

starts

as

soon

as

electrode

touches

the

workpiece.

1

Workpiece

Make

sure

workpiece

is

clean

be

fore

welding.

2

Work

Clamp

Place

as

close

to

the

weld

as

possi

ble.

3

Electrode

A

small

diameter

electrode

re

quires

less

current

than

a

large

one.

Follow

recommendations

of

electrode

manufacturer

when

set

ting

weld

amperage

(see

Figure

8-2).

4

Insulated

Electrode

Holder

5

Electrode

Holder

Position

6

Arc

Length

Arc

length

is

the

distance

from

the

electrode

to

the

workpiece.

A

short

arc

with

correct

amperage

will

give

a

sharp,

crackling

sound.

7

Slag

Use

a

chipping

hammer

and

wire

~

brush

to

remove

slag.

Remove

slag

and

check

weld

bead

before

making

another

weld

pass.

ST-151

593

4

4

2

7

Tools

Needed:

Figure

8-1.

Shielded

Metal

Arc

Welding

(SMAW)

Procedure

OM-160

518

Page

20