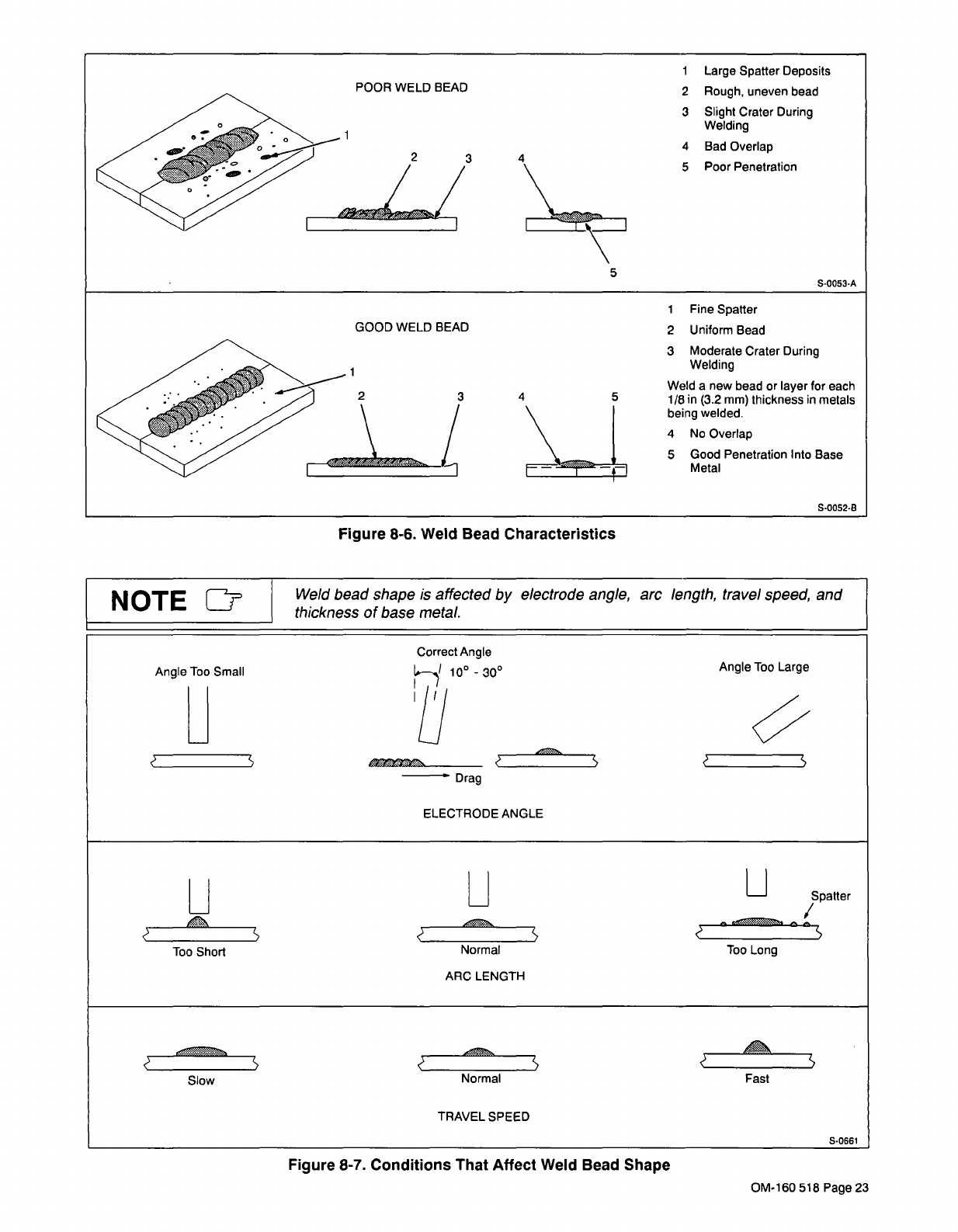

POOR

WELD

BEAD

1

Large

Spatter

Deposits

Figure

8-6.

Weld

Bead

Characteristics

Figure

8-7.

Conditions

That

Affect

Weld

Bead

Shape

2

Rough,

uneven

bead

3

Slight

Crater

During

Welding

4

Bad

Overlap

34~

5

Poor

Penetration

5

GOOD

WELD

BEAD

1

Fine

Spatter

S-0053.A

4

2

Uniform

Bead

3

Moderate

Crater

During

Welding

Weld

a

new

bead

or

layer

for

each

5

1/8

in

(3.2

mm)

thickness

in

metals

being

welded.

4

No

Overlap

5

Good

Penetration

Into

Base

Metal

S-0052-B

Angle

Too

Small

H

NOTE

~

Weld

bead

shape

is

affected

by

electrode

angle,

arc

length,

travel

speed,

and

______________________

thickness

of

base

metal.

Correct

Angle

Angle

Too

Large

Drag

ELECTRODE

ANGLE

Li

L_]

Spatter

Too

Short

Normal

Too

Long

ARC

LENGTH

Slow

Normal

Fast

TRAVEL

SPEED

S-066

1

OM160

518

Page

23