. A complete Parts List is available at www.MillerWelds.com

OM-4430 Page 24

SECTION 6 − OPERATING WELDING GENERATOR

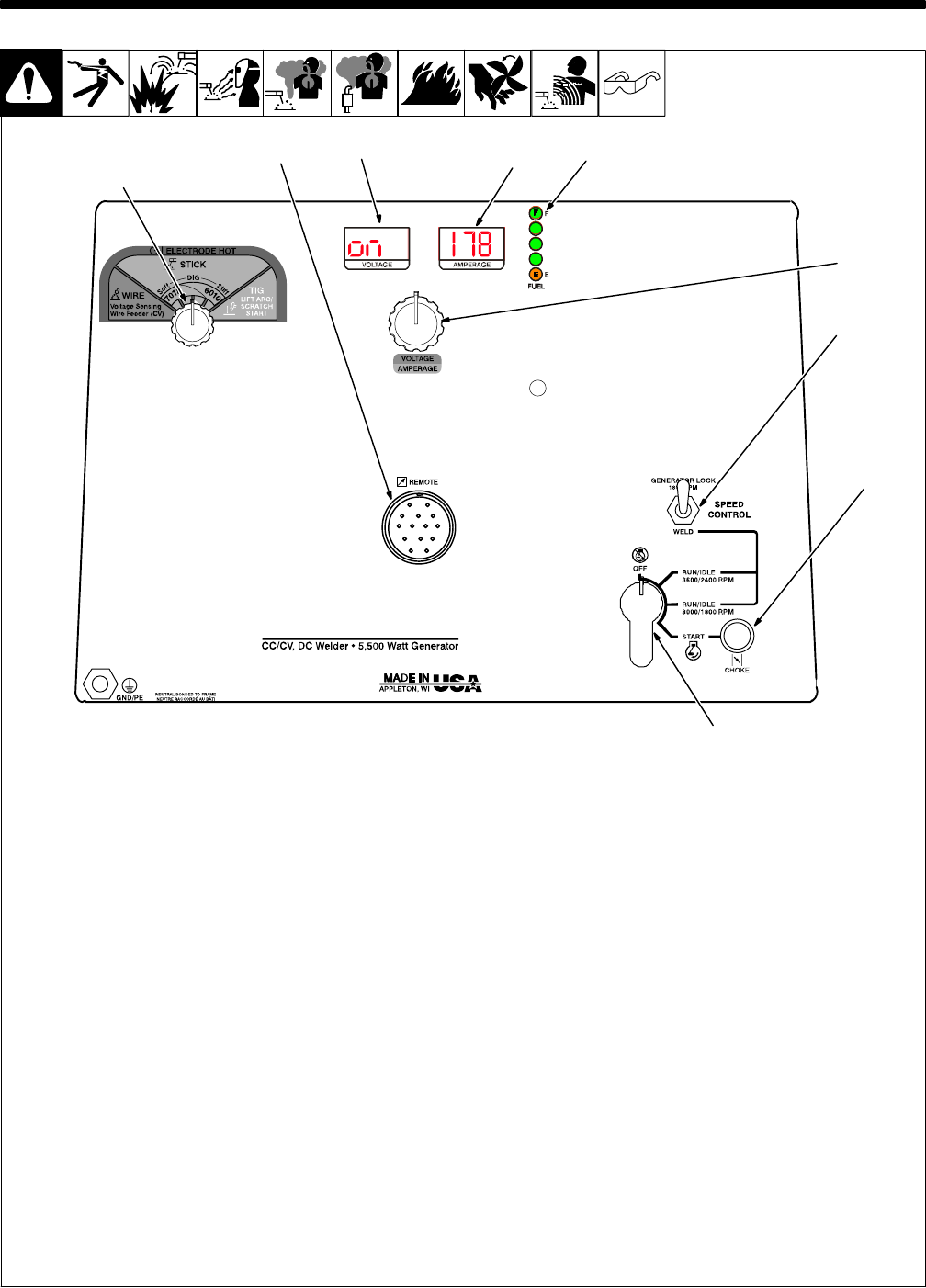

6-1. Front Panel Controls

2

1

4

3

Ref 216 172-D

7

5

6

8

9

1 Process Switch

See Section 6-5 for Process switch informa-

tion.

2 Remote Receptacle

Use receptacle to connect remote control.

When a remote voltage/amperage control is

connected to the Remote receptacle, the

Auto Sense Remote feature automatically

switches voltage/amperage control to the re-

mote control (see Sections 5-7 and 6-8).

With remote voltage/amperage control con-

nected, weld output in CC mode is deter-

mined by a combination of front panel and re-

mote control voltage/amperage settings.

If no remote voltage/amperage control is

connected to the Remote receptacle, the

front panel Voltage/Amperage control ad-

justs voltage and amperage.

3 And 4 Displays

Displays can show weld process information

(voltage and amperage) or maintenance in-

formation (hourmeter or oil change count-

down).

Meter Weld Functions: In Wire mode, Volt-

meter displays preset weld voltage when not

welding. Meters display actual voltage and

amperage when welding and for five sec-

onds after welding has stopped.

In Stick and TIG modes, Voltmeter reads ON

and Ammeter displays preset amperage

when not welding. Meters display actual volt-

age and amperage when welding and for five

seconds after welding has stopped.

Meter Engine Maintenance Functions:

Meters display engine hours when Engine

Control switch is in the Run/Idle 3600/2400

position but engine is not running.

Meter Oil Change Countdown: With en-

gine off, place Engine Control switch in Run/

Idle 3000/1800 position to see hours before

next recommended oil change. Oil change

hours start at 100 (fresh oil) and count down

to 0 (oil change due). The meters display

negative (−) hours if 100 hours is exceeded.

After changing oil, reset counter by cycling

Engine Control switch between Run/Idle

positions three times.

Place Engine Control switch in Off position

after reading meters.

5 Fuel Level Indicator

With Engine running or Engine Control

switch in either Run/Idle position, LED’s indi-

cate fuel left in tank.

6 Voltage/Amperage Control

Use control to select weld voltage or

amperage. Control may be adjusted while

welding.

. For maximum weld output (above 220

Amps), run unit at 3600 rpm. For weld

output below 220 Amps, operate unit at

3000 or 3600 rpm.

With Process switch in any Stick or TIG set-

ting, use control to adjust amperage. With

Process switch in Wire position, use control

to adjust voltage. When a remote voltage/

amperage control is connected to Remote

receptacle RC4, control sets the maximum

amperage in Stick and TIG modes, but has

no effect in MIG mode.

7 Engine Control Switch (see Section 6-2)

8 Engine Choke Control (see Section 6-2)

9 Engine Speed Control Switch (see Sec-

tion 6-2)