OM-225 590 Page 19

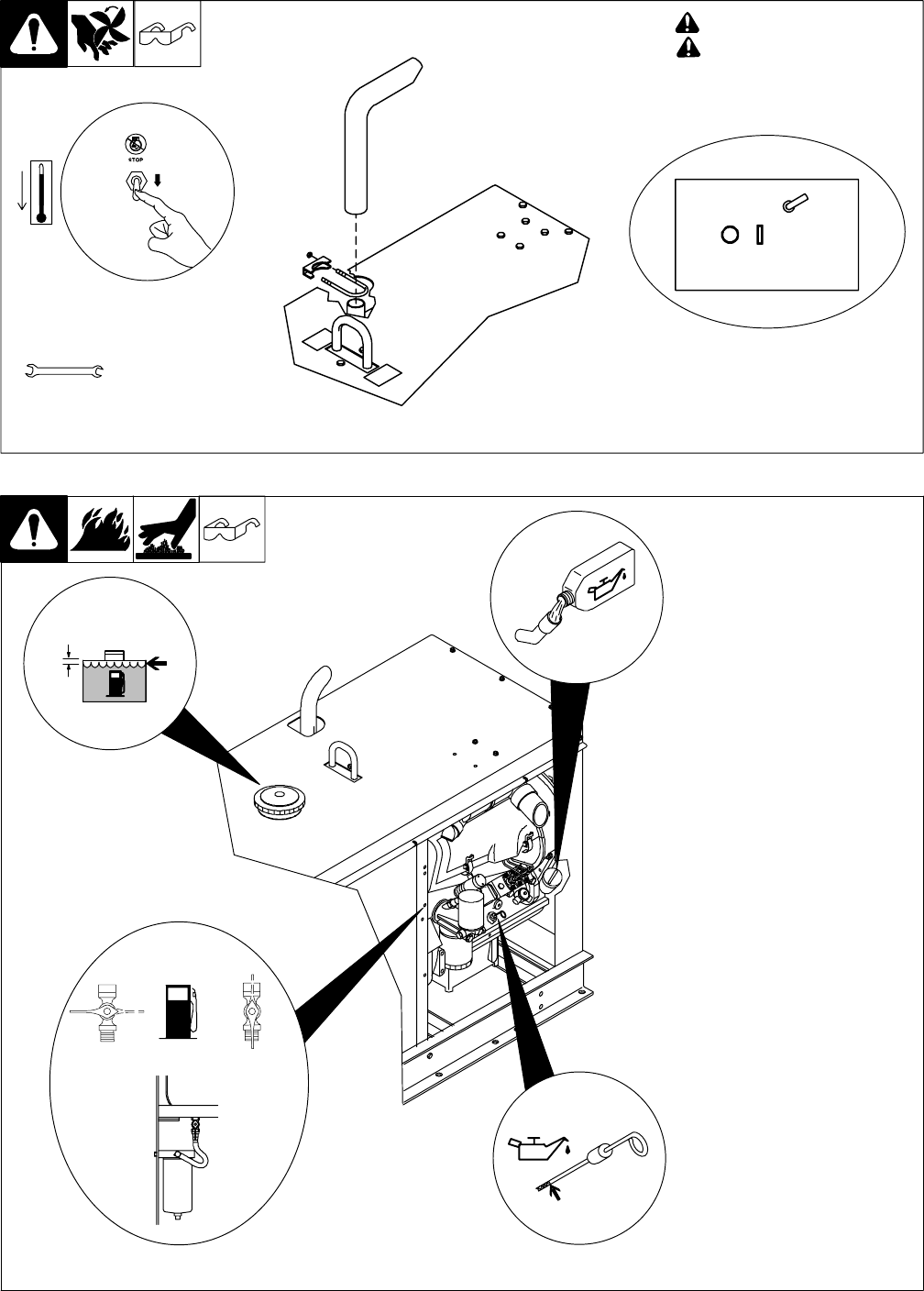

5-4. Installing Exhaust Pipe

! Stop engine and let cool.

1/2 in

Tools Needed:

exh_pipe2 4/96 − 154 089-A / 154 611 / 190 377

! Do not blow exhaust toward

air cleaner or air intake.

Top View

5-5. Engine Prestart Checks

Full

1/2 in

(13 mm)

Full

Ref 804 285 / 013 466

Diesel

Check all fluids daily. Engine must

be cold and on a level surface.

Follow run-in procedure in engine

manual. If unburned fuel and oil col-

lect in exhaust pipe during run-in,

see Section 10.

Fuel

NOTICE − Do not use gasoline.

Gasoline will damage engine.

Add diesel fuel before starting

engine the first time (see mainte-

nance label for specifications). Fill

fuel tank up to 1/2 in. (13 mm) from

top to allow room for expansion.

Open fuel shut-off valve.

Do not run out of fuel or air enters

fuel system and causes starting

problems. Use primer pump to

prime injector system (see Section

8-7).

Oil

After fueling, check oil with unit on

level surface. If oil is not up to full

mark on dipstick, add oil (see main-

tenance label).

. Engine stops if oil pressure is

too low.

. To improve cold weather

starting:

Keep battery in good condition.

Store battery in warm area.

Use fuel formulated for cold

weather (diesel fuel can gel in

cold weather). Contact local

fuel supplier for fuel in-

formation.

Use correct grade oil for cold

weather.

OFF

FUEL ON