OM-225 590 Page 31

ether1 7/96 − 153 382-A / 225 543 / 804 289-A

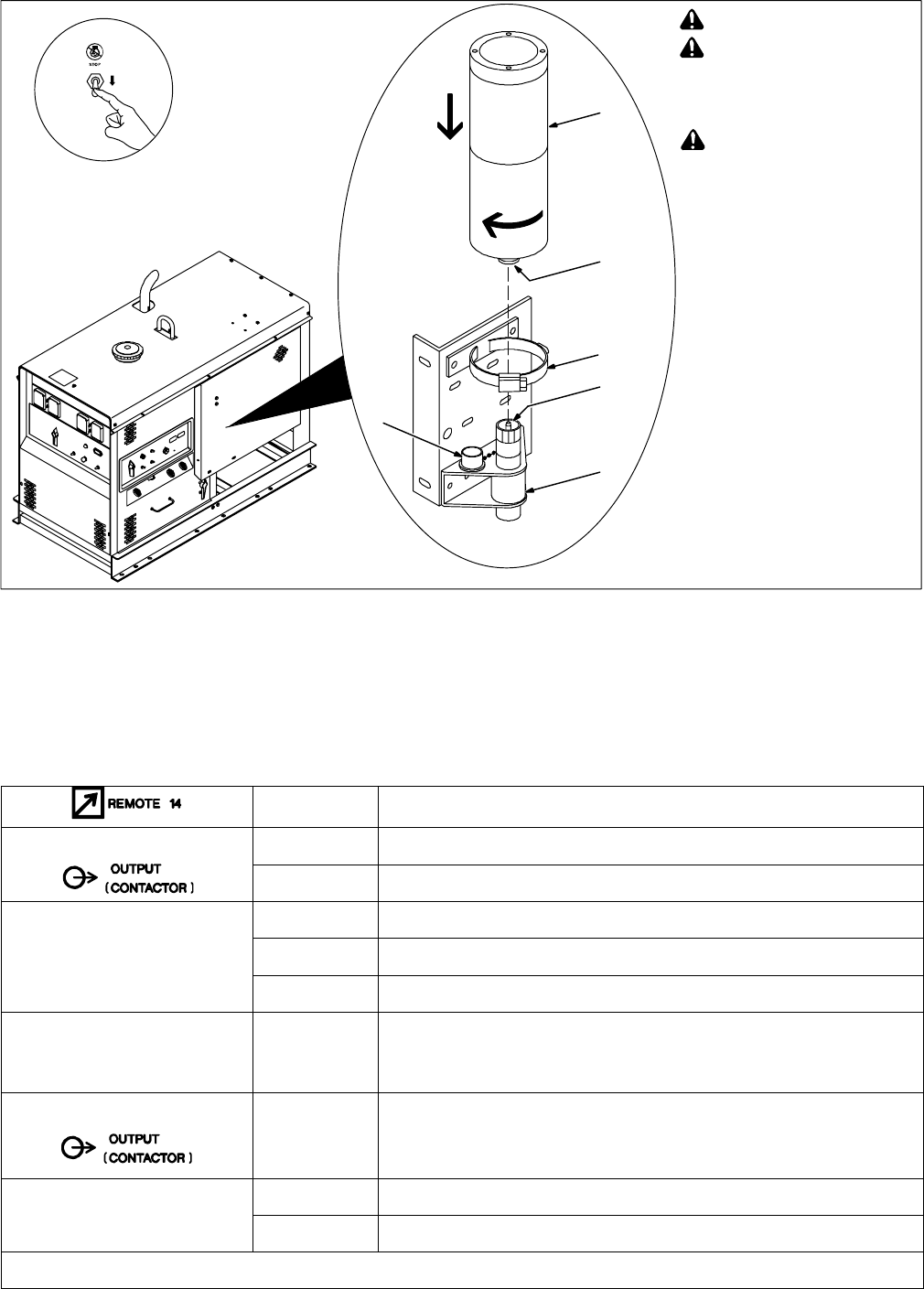

! Stop engine.

! Improper handling or expo-

sure to ether can harm your

health. Follow manufactur-

er’s safety instructions on

cylinder.

! Do not use Ether Starting Aid

while engine is running.

Open right side door.

1 Ether Cylinder

2 Nozzle

Remove cover and clean cylinder

nozzle.

3 Clamp

4 Fitting

5 Cap

6 Valve

Remove cap and clean fitting.

Install cylinder on fitting. Tighten

clamp.

. After installing cylinder, wait at

least 10 minutes before using

to let ether particles settle and

prevent atomizer plugging.

Put cap on fitting when cylinder is

removed.

5-16. Installing Ether Cylinder (Optional Ether Starting Aid)

1

2

3

4

6

5

5-17. Remote 14 Receptacle Information

. Place Welder Selector switch in Welder A/Welder B position (dual operator mode) for both remote receptacles to work. Welder A (left) remote

receptacle output contactor and control is disabled when switch is in Welder B position.

Socket* Socket Information

24 VOLTS AC

A 24 volts ac. Protected by supplementary protectors CB5 and CB6.

B Contact closure to A completes 24 volts ac contactor control circuit.

REMOTE

C Output to remote control; +10 volts dc in CV, 0 to +10 volts dc in CC.

REMOTE

OUTPUT

CONTROL

D Remote control circuit common.

CONTROL

E 0 to +10 volts dc input command signal from remote control.

A/V

AMPERAGE

VOLTAGE

F

H

Current feedback; 0 to +10 volts dc, 1 volt per 100 amperes.

Voltage feedback; +1 volts dc per 10 arc volts.

115 VOLTS AC

I

J

115 volts, 15 amperes, 60 Hz ac. Protected by supplementary protectors CB5 and

CB6.

Contact closure to I completes 115 volts ac contactor control circuit.

GND

K Chassis common.

GND

G Circuit common for 24 and 115 volts ac circuits.

*The remaining sockets are not used.