OM-225 590 Page 52

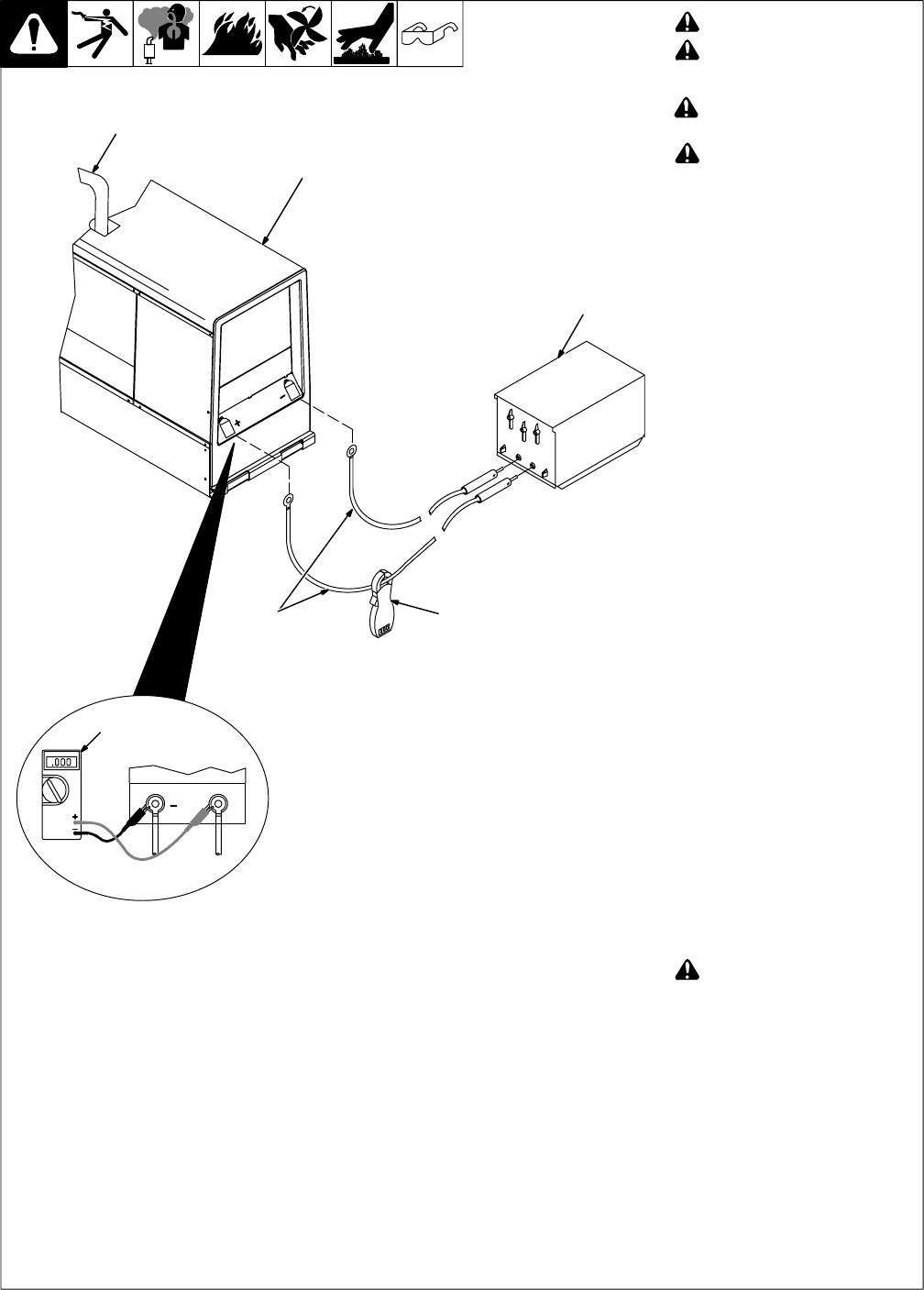

10-3. Run-In Procedure Using Resistance Grid

S-0684

! Stop engine.

! Do not touch hot exhaust

pipe, engine parts, or load

bank/grid.

! Keep exhaust and pipe away

from flammables.

! Do not perform run-in

procedure at less than 20

volts weld output and do not

exceed duty cycle or equip-

ment damage may occur.

1 Resistance Grid

Use grid sized for generator rated

output.

Turn Off grid.

2 Welding Generator

Place Welder Selector switch in

Welder B position (600 Amps), A/V

control in minimum position, and

both Process Selector switches in

Stick/TIG position.

3 Weld Cables

Connect grid to generator Welder B

(right) weld output terminals using

proper size weld cables with cor-

rect connectors (polarity is not im-

portant).

4 Voltmeter

5 Clamp-On Ammeter

Connect voltmeter and ammeter as

shown, if not provided on generator.

Start engine and run for several

minutes.

Set grid switches and then adjust

generator A/V control so load

equals 350 Amps at 40 volts.

Check generator and meters after

first five minutes then every fifteen

minutes to be sure generator is

loaded properly.

. Check oil level frequently dur-

ing run-in; add oil if needed.

It is recommended to run the weld-

ing generator for two hours mini-

mum and up to four hours under

load. Place A/V control in minimum

position, then shut down grid to

remove load. Run engine several

minutes at no load.

! Stop engine and let cool.

6 Engine Exhaust Pipe

Repeat procedure if wetstacking is

present.

1

3

5

+

4

2

6