. A complete Parts List is available at www.MillerWelds.com

OM-1327 Page 28

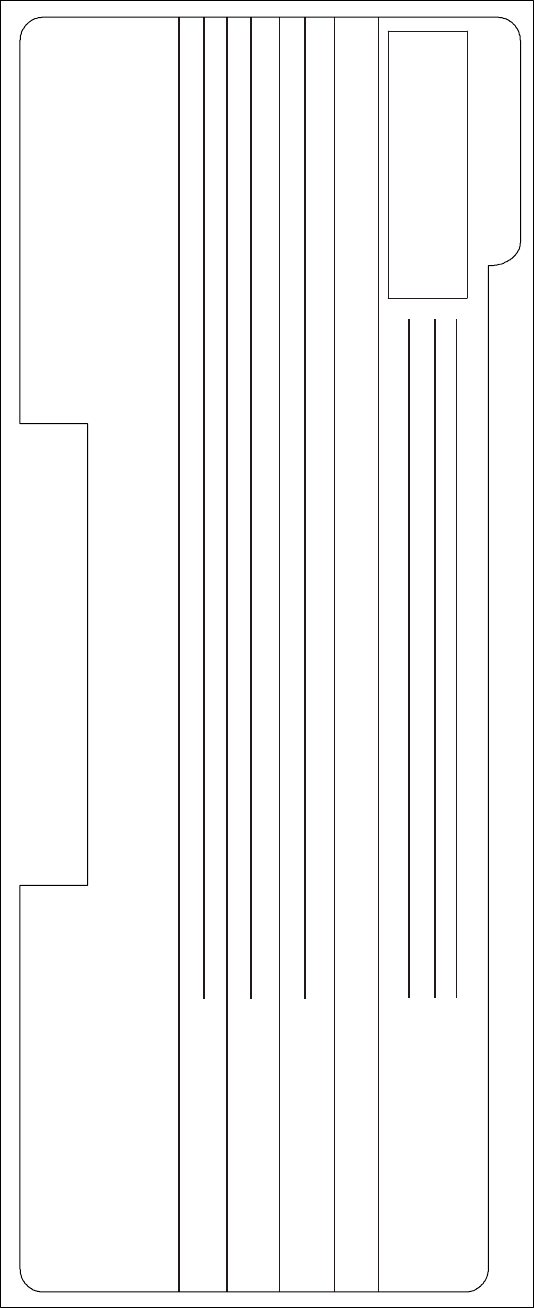

4-9. Weld Parameters For MIG Mode

Material

Steel

Steel

Aluminum

Stainless Steel

Gas

100% Co

2

75% Argon

25% Co

2

90% Helium

7.5% Argon

2.5% Co

2

100% Argon

Wire

1/2” 3/8” 1/4” 3/16” 1/8” 14ga 16ga 18ga 20ga 22ga

3/64 5356 24.0/535 23.5/500 22.5 /465 21.0 /375 19.0 /340

.035 4043

3/64 4043

.035 5356

−

23.5/700 18.2/300

24.0/475 23.5/435 23.0/375 21.5/305 19.5/250

−

Inductance = 20−40

23.5 /220

Volts/Wirefeed

Reference

Inductance = 20−40

Inductance = 60−80

Inductance = 30

.035

.035

.045

−

23.0 /325 21.5 /280 20.5 /240 20.0/210 19.0 /175 18.5/160 18.0/115 17.0/90 16.5/80

28.5 /485 19.5 /330 18.5 /275 18.0 /260 16.5 /200 16.0/155 15.5/135 15.0/100 14.5/95

USE SPRAY 19.0/220 18.0 /200 17.5 /170 16.2 /150 16.0/130 15.5/100 −

24.0/400 23.0/300 20.5/250 20.0/235 19.5/175 19.0/160

.045

.045

.035

−

23.0 /220 21.5 /200 20.5 /175 20.0 /150 19.0 /110 18.5/105 − − −

− 25.0 /450 22.5/440 21.5 /375 21.0/325 20.0/275 18.0/235 18.5/200 17.5/150 −

29.3/530

(12.7mm) (9.5mm)

(6.4mm)

(4.8mm) (3.2mm) (2.0mm) (1.6mm) (1.2mm) (0.9mm) (0.8mm)

Note: All chart parameters reference settings for Horizontal T fillet welds. Settings may need

to be modified for other types of welding joints or welding positions.

MIG CHART MIG CHART

Metal Core

Inductance = 30

.045

26.0/400 24.5/350 23.5/300

90% Argon

10% Co

2

−− −−

−−−−−

27.0/42529.0/475

−

19.2/380

19.0/450

21.5/450

21.0/520

23.0/530

23.0/66023.5/800